Designing a simple electronic component LED experiment requires detailed consideration of many factors, including the working principle of the LED, the required electronic components, circuit design and manufacturing process.

The process is introduced in detail below, but please note that this is a simple LED experimental example designed with electronic components. To learn more, please bookmark and follow our website, or contact us.

You may need to consult more information or guidance to obtain complete understanding and operational details.

All work on the LED project requires the selection and purchase of electronic components according to your needs.

Understand how LEDs work

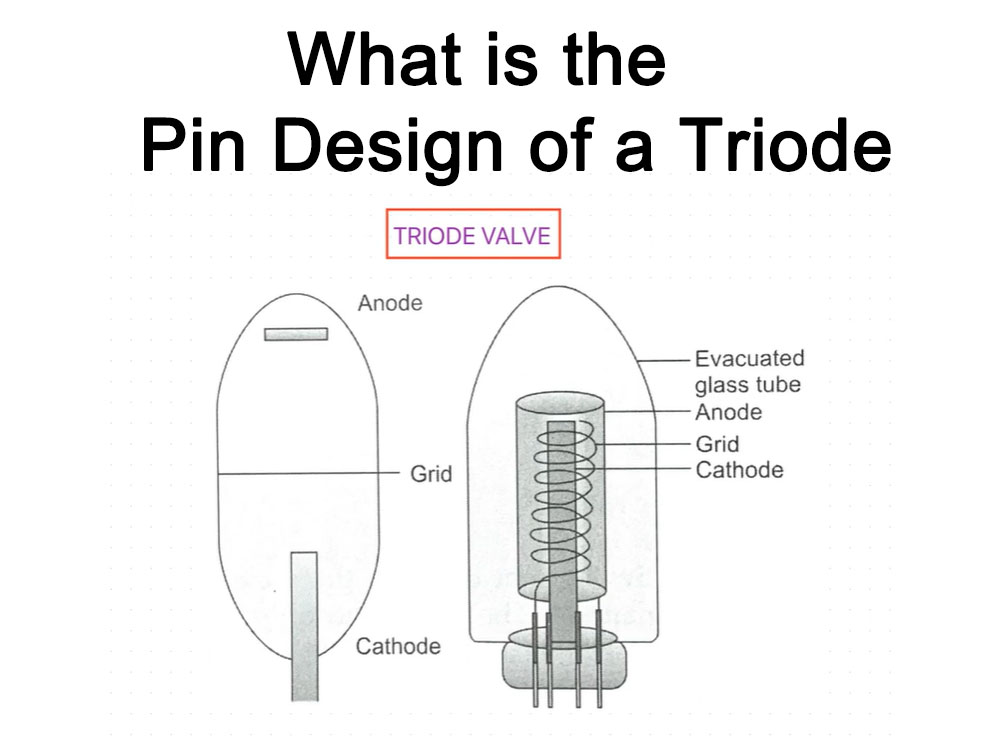

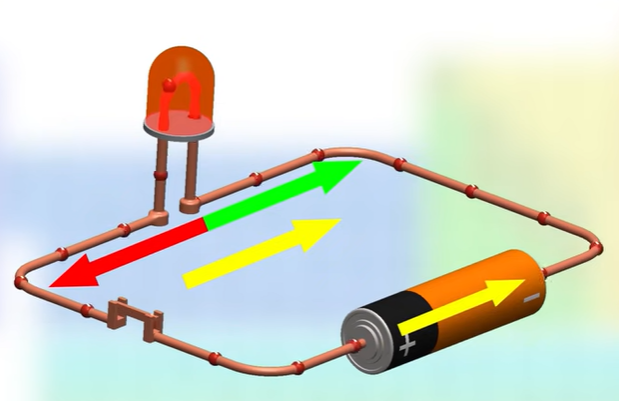

- LED (Light Emitting Diode) is a special electronic device that emits light when electric current passes through it. Its working principle is based on the characteristics of the PN junction. When forward biased, current flows from the anode to the cathode, and photons are emitted.

- There are many types of LEDs with different colors. Common colors include red, green, blue and other colors. The wavelength of their light is determined by the materials used in the manufacturing process.

Select the required electronic components

- LED: Choose an LED that suits your experimental needs, such as color, size, and brightness.

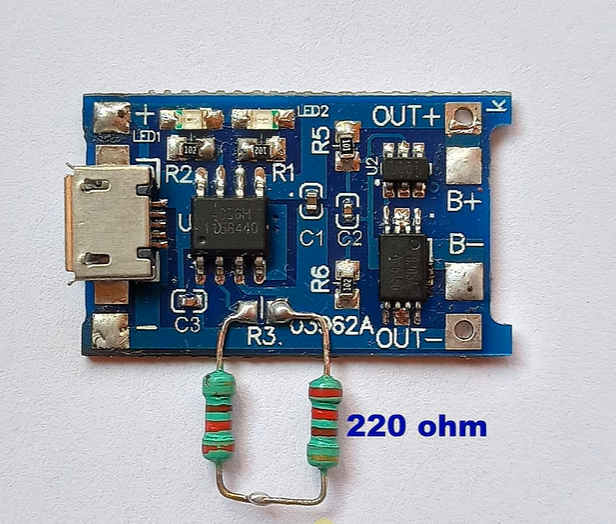

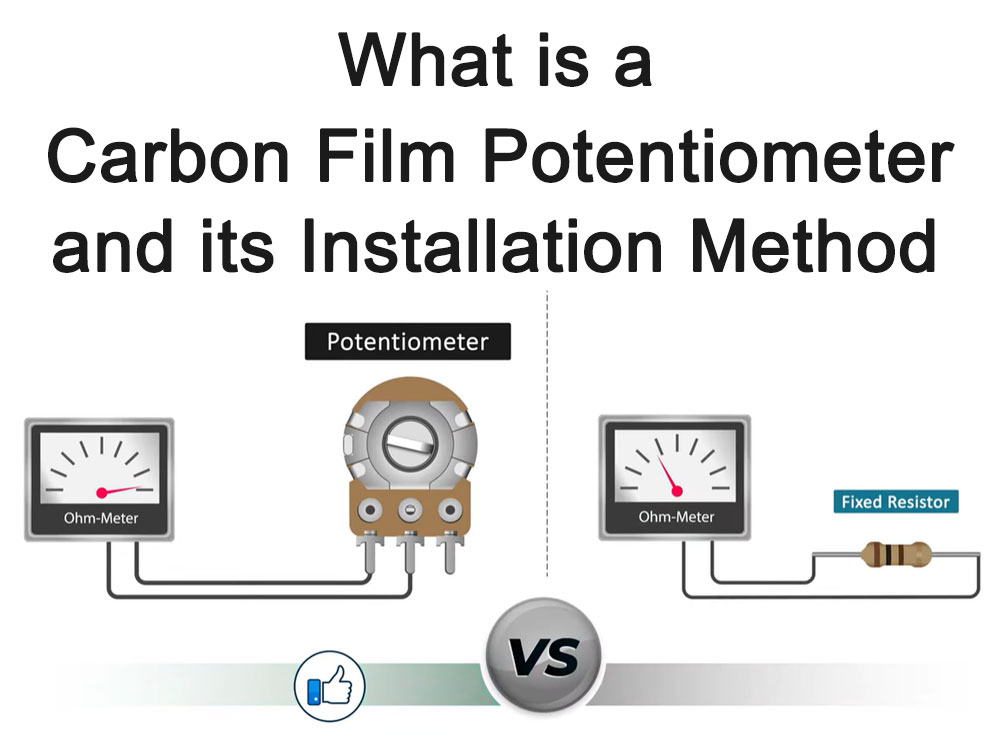

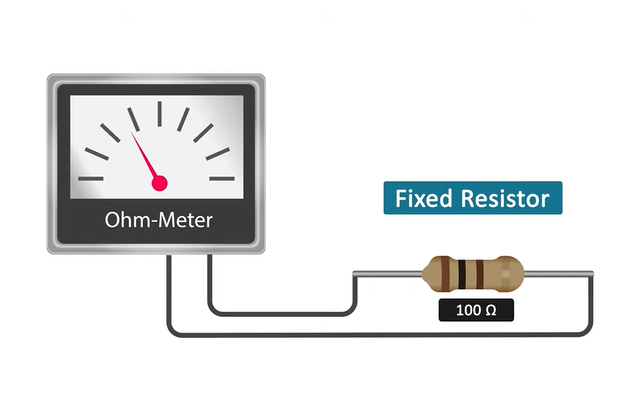

- Resistor: used to limit the current flowing through the LED to protect the LED from damage due to excessive current. The formula for calculating the required resistor value is: R = V/I, where R is the resistor value, V is the supply voltage, and I is the current expected to flow through the LED.

- Capacitor: used to filter noise in the circuit and protect the LED.

- Battery or power supply: Provides power to the LED.

- Breadboard: used to build and test circuits.

- Wires: used to connect various components.

Design circuit

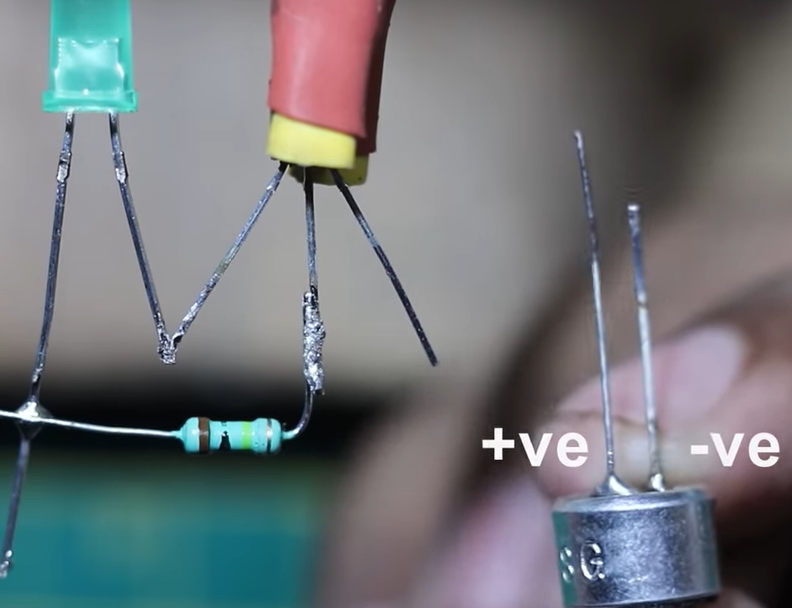

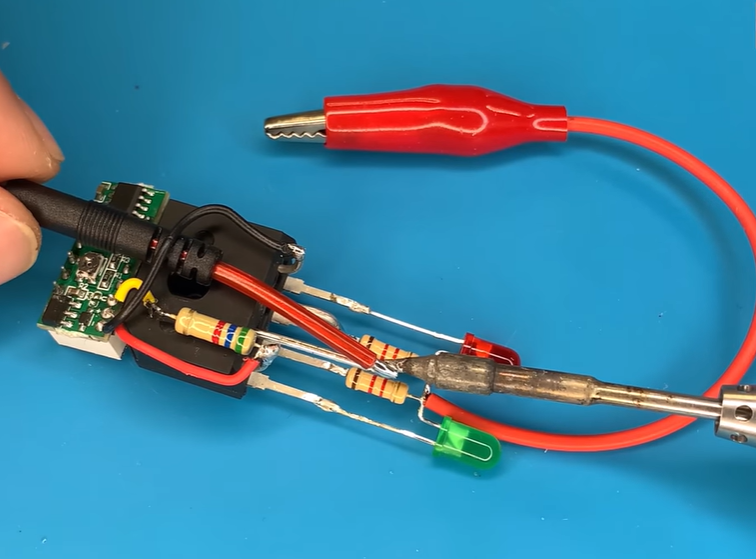

- Determine the positive and negative poles of the LED. Generally speaking, the long leg is the positive pole and the short leg is the negative pole.

- Design a simple circuit to connect the battery, resistor and LED. Make sure the resistor is connected between the positive terminal of the LED and the battery to limit the current flow.

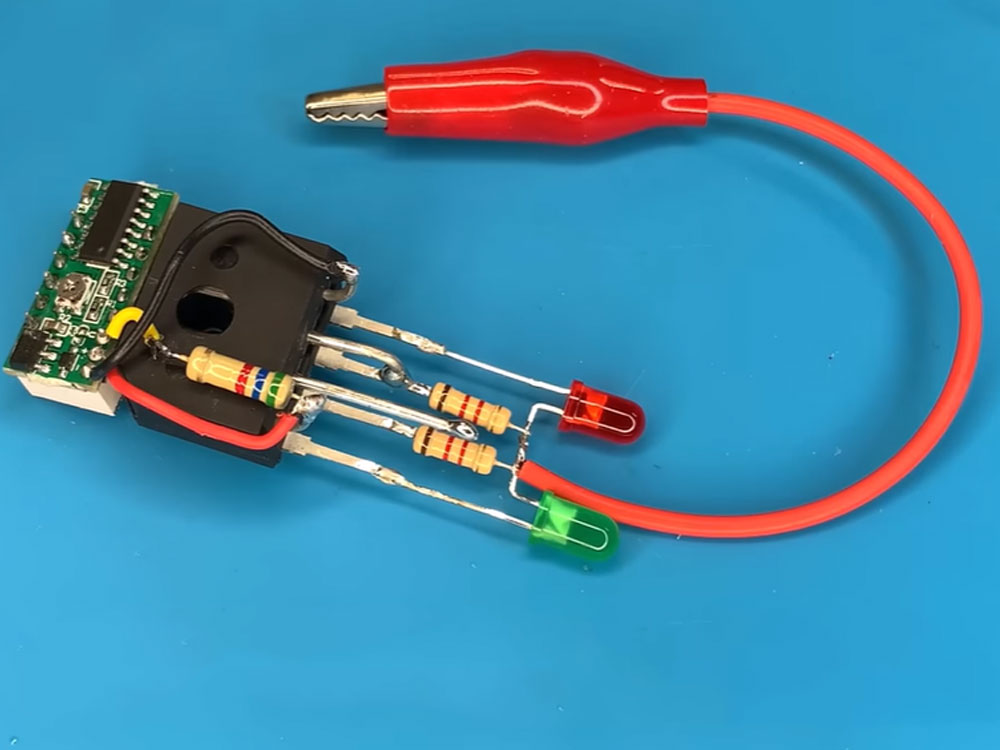

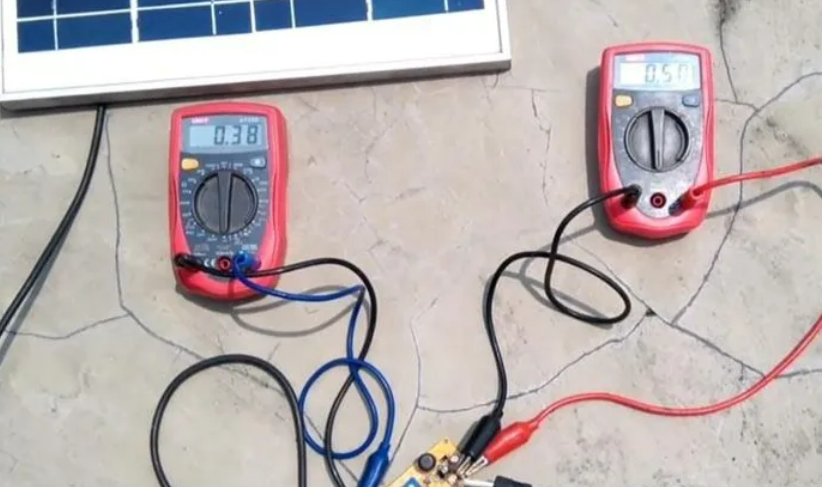

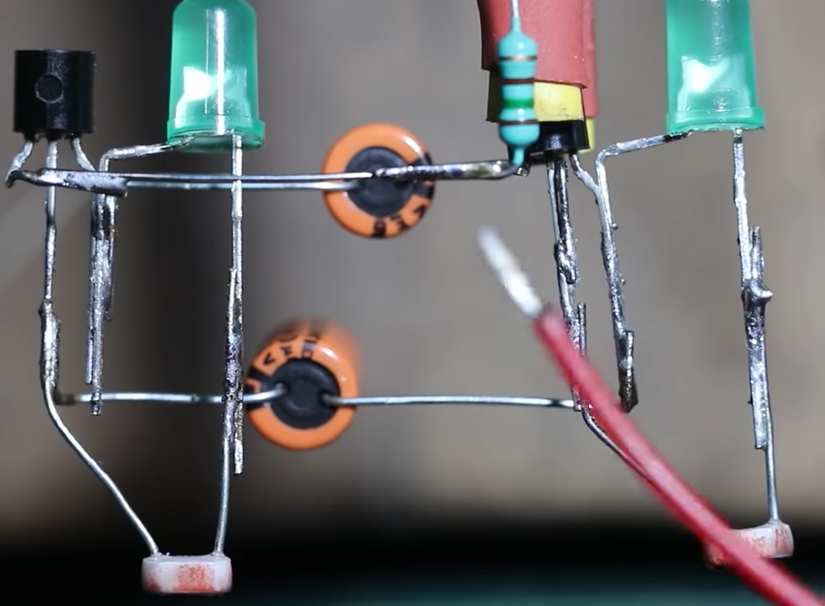

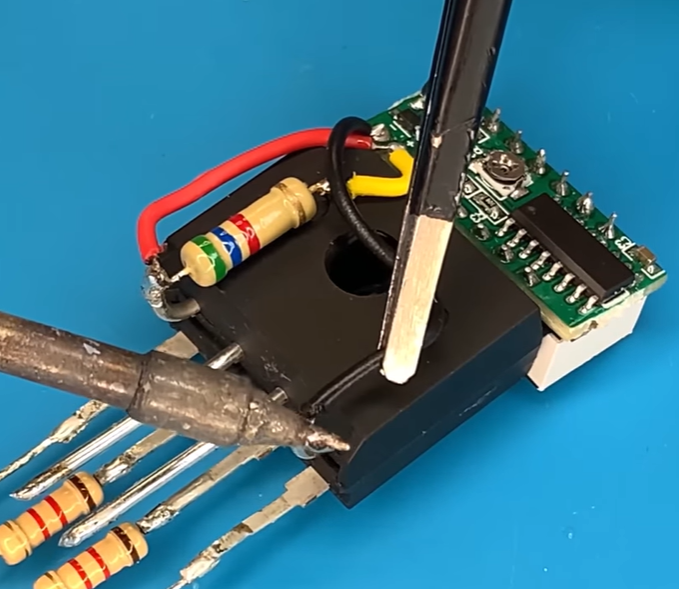

Build and test circuits

- Place all components on the breadboard and connect them using wires.

- Make sure all connections are tight and there is no risk of short circuit.

- Add power and observe whether the LED glows. If the LED does not light up, check that the connections are correct and that all components are working properly.

- Adjust the brightness of the LED by changing the resistor value or battery voltage.

Further experimentation and exploration

- Try using LEDs of different colors to observe their lighting effects under the same conditions.

- Use multiple LEDs to design different display modes or patterns.

- Connect the LED to the microcontroller and explore ways to program the LED to turn on and off.

- Explore using different types of LEDs, such as ultra-bright LEDs or infrared LEDs.

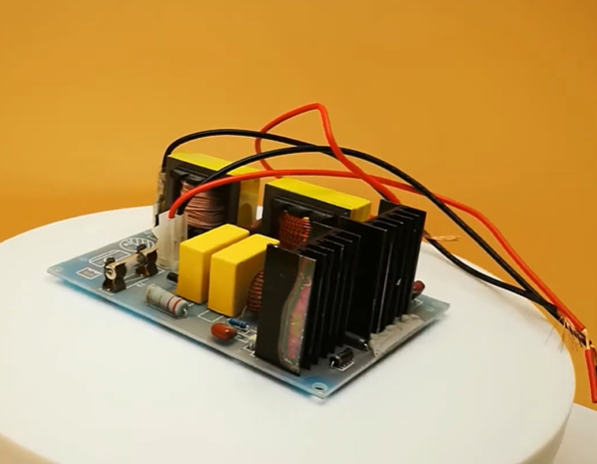

- Try connecting the LED to another type of power supply, such as AC power or an adjustable power supply.

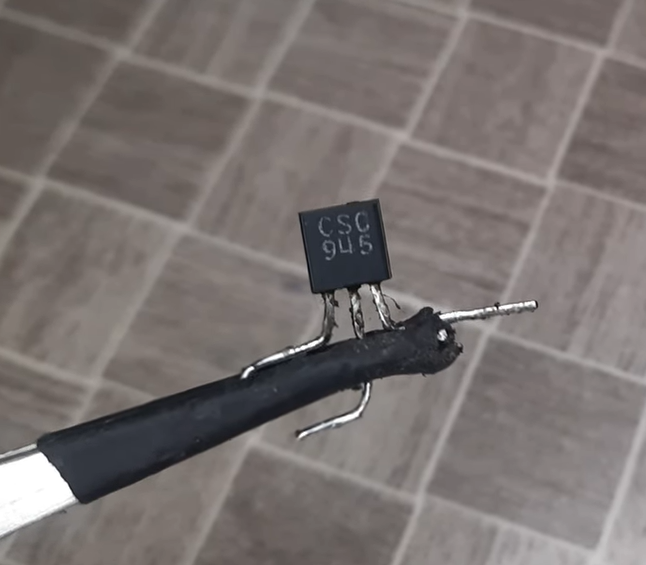

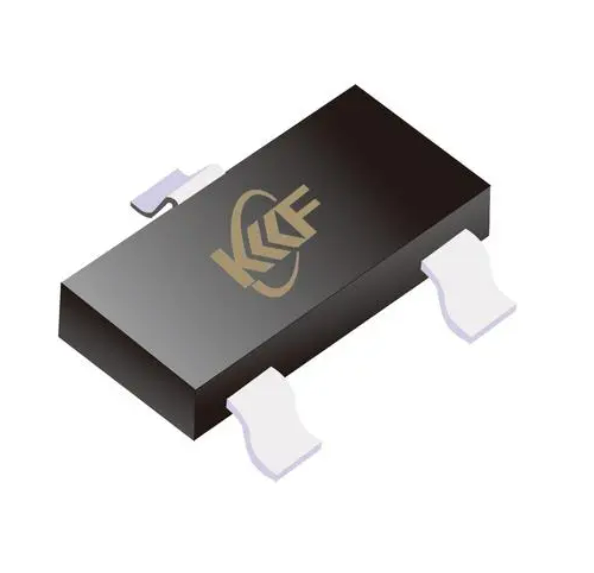

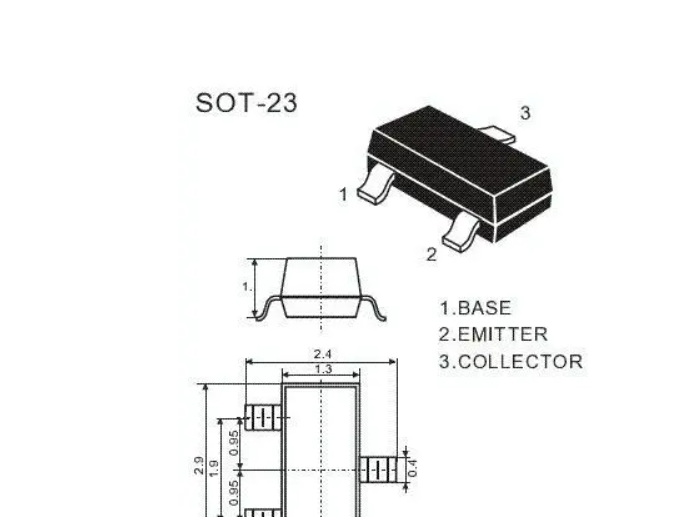

- Extend the experiment by adding other electronic components, such as using transistors to implement more complex control logic.

Safety Precautions

- Always use caution and follow basic safety guidelines when handling circuits and electronic components.

- Avoid short circuit or overload during operation to avoid damage to electronic components or risk of fire.

- Make sure the power supply voltage matches the rated voltage of the electronic component and avoid using too high or too low voltage.

- After the experiment, remember to disconnect the power supply and clean the work area.

- If you encounter difficulties or problems, seek professional guidance or consult relevant professionals.

Through this simple electronic component LED experiment, you can gain an in-depth understanding of the working principle of LED, electronic circuit design and basic electronic operation skills. Through continuous experimentation and exploration, you can expand your knowledge and improve your skill level. Remember to always focus on safety issues and follow correct operating procedures and technical requirements.

Understand the relationship between LED brightness and current

The brightness of an LED is directly related to the current flowing through it. By adjusting the resistor value in the circuit, you can change the current flowing through the LED, thereby adjusting the brightness of the LED. This characteristic makes LED a flexible light source that can be used in a variety of different application scenarios.

Understand the lifespan and reliability of LEDs

LEDs generally have longer lifespans because they are less prone to failure under normal operating conditions. However, if the current is too high or the temperature is too high, the LED may be damaged. Therefore, when designing a circuit, you should consider using appropriate protection components, such as resistors and capacitors, to ensure the normal operation of the LED.

Explore different LED applications

LEDs are used in a wide range of applications, including but not limited to lighting, displays, indicators, backlights, communications, etc. Through this experiment, you can explore the application of LEDs in various scenarios and understand their working principles and design requirements.

Cultivate practical ability and innovative spirit

By designing and building circuits with your own hands, you can develop your practical skills and innovative spirit.

Experiment with different circuit designs and component combinations to explore new applications and solutions. Along the way, you may encounter various problems, but by solving them, you can continue to grow and learn.

In general, through this simple electronic component LED experiment, you can have an in-depth understanding of the working principle, circuit design and electronic operation skills of LED.

At the same time, you can also cultivate your practical ability and innovative spirit, laying a solid foundation for future study and work.

I hope this experiment can stimulate your interest and enthusiasm for electronics and lead you to a broader world of technology.

Frequently Asked Questions

Because the characteristic of LED is forward conduction, forward voltage must be applied to both ends of it to light up. Usually the power supply is 5V. If no resistor is added, the current will be very large after being directly connected to the power supply, and it is easy to burn the LED. Adding a resistor can limit the current and protect the LED from being burned.

The anode of the LED is the positive pole and is connected to the positive pole of the power supply; the cathode is the negative pole and is connected to the negative pole of the power supply. If connected reversely, the LED will not light up and may burn out. Therefore, special attention is required when designing and connecting circuits.

Choosing the appropriate resistor depends on the rated voltage and current of the LED. For example, if you are using a 2V, 20mA LED, you can choose a 300 ohm resistor. The calculation formula is: (power supply voltage – LED voltage) / LED current = resistance value.

Connect one end of the LED to the positive terminal of the power supply and the other end to the negative terminal of the power supply through a resistor. Be careful not to connect the positive and negative poles of the LED directly, otherwise the LED will burn out.

You can tell whether it is working properly by observing whether the LED lights up. If the LED can light up after forward voltage is applied to both ends, then the LED is normal. If the LED does not light up, you can check whether the circuit is connected normally, or replace the LED with a new one for testing.