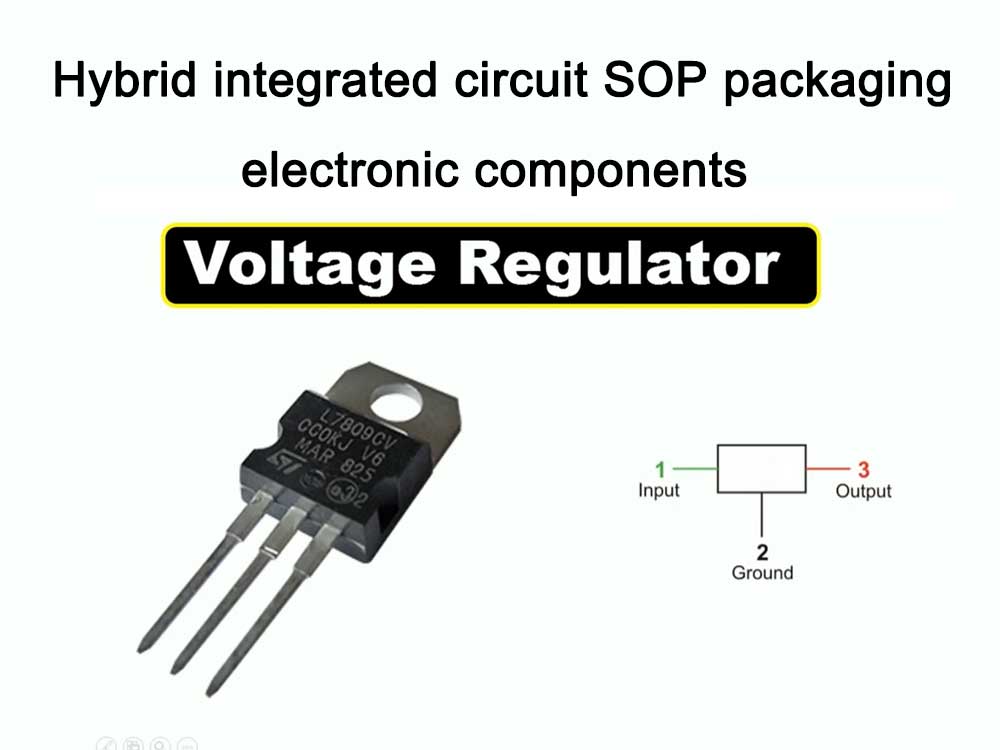

Hybrid integrated circuit SOP packaging electronic components

Hybrid integrated circuit SOP packaging, as an important technology in modern electronic manufacturing, combines the high integration level of hybrid integrated circuits and the advantages of SMT technology.

This article will conduct an in-depth discussion of the development history, technical advantages, and precautions for use of hybrid integrated circuit SOP packaged electronic components.

The development history of hybrid integrated circuit SOP packaging

Since the early 1970s, with the rapid development of microelectronics technology, integrated circuits have begun to be widely used in various electronic products. In the 1980s, the emergence of surface mount technology (SMT) brought about revolutionary changes in the packaging form of electronic components. As a type of SMT, SOP packaging has quickly become a mainstream technology in the field of electronic manufacturing due to its characteristics of miniaturization, lightweight and high integration.

Technical advantages of hybrid integrated circuit SOP packaging

- Miniaturization and lightweight: SOP packaging technology greatly reduces the size of electronic components, thereby realizing the miniaturization and lightweight of electronic products and meeting the needs of modern electronic products for portability.

- High integration: Hybrid integrated circuit technology integrates multiple electronic components on one substrate, which greatly improves the integration of the circuit and reduces the space occupied by the circuit board.

- High reliability: SOP packaging technology improves the mechanical strength and environmental resistance of components, reduces damage caused by environmental factors, and improves the reliability of electronic products.

- Low cost: Because SOP packaging technology improves production efficiency and reduces the consumption of raw materials, it can effectively reduce production costs.

Precautions for hybrid integrated circuit SOP packaging

- Component selection: When selecting hybrid integrated circuit SOP packaged electronic components, full consideration should be given to their electrical performance, mechanical performance, thermal performance and other parameters to ensure that they can meet actual application needs.

- Welding quality: When welding SOP components to the circuit board, the welding quality should be ensured to prevent virtual welding, cold welding and other phenomena from affecting the performance and reliability of electronic products.

- Environmental adaptability: Since hybrid integrated circuit SOP packaged electronic components are relatively sensitive to the environment, the impact of extreme temperature, humidity, salt spray and other environmental conditions on the components should be avoided during use.

- Maintenance and repair: The assembled hybrid integrated circuit SOP package circuit board should be maintained and inspected regularly. If any fault is found, it should be repaired in time to ensure its normal operation and extend its service life.

- Waste disposal: Wasted hybrid integrated circuit SOP packaged electronic components and circuit boards should be properly disposed of in accordance with relevant environmental protection regulations to avoid environmental pollution.

Conclusion on SOP packaged electronic components

Hybrid integrated circuit SOP packaged electronic components are widely used in various fields due to their unique technical advantages. With the continuous development of science and technology, I believe that hybrid integrated circuit SOP packaging technology will be further improved, bringing more innovations and breakthroughs to the electronics manufacturing industry. At the same time, for companies and engineers who use this technology, fully understanding and mastering its technical characteristics and precautions are the key to ensuring the performance and reliability of electronic products.