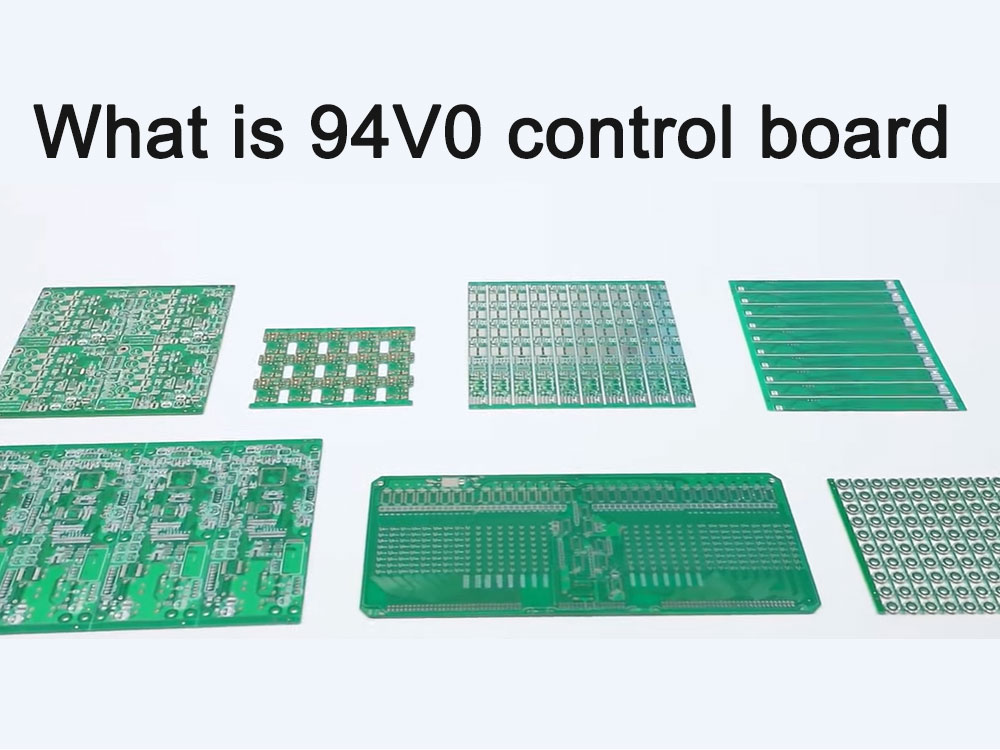

What is 94V0 control board

The 94V0 control board is an electronic control board that complies with the V-0 level in the UL94 standard.

The UL94 standard is an internationally widely used flammability performance evaluation standard for plastic materials. It is mainly used to evaluate the burning speed, burning time, dripping resistance and whether dripping beads burn after the material is ignited.

94V0 is the highest grade in this standard, which represents extremely low flammability and smoke generation, so it is widely used in situations with extremely high fire protection requirements.

Features of 94V0 control board

- Extremely low flammability: The 94V0 level control panel showed extremely low flammability in the test. When exposed to external fire sources, it will extinguish itself in a short period of time and will not continue to burn.

- Low Smoke Generation: During the combustion process, the 94V0 rated control panel generates extremely low amounts of smoke, which helps reduce reduced visibility and suffocation risks in fires.

- High heat resistance: 94V0 grade raw materials can withstand high temperatures up to 1050°C, which allows the control board to maintain stable performance in extreme environments.

- Wide application fields: Due to its excellent fire protection performance, 94V0 control board is widely used in servers, data centers, industrial equipment, medical equipment, aerospace and other fields, as well as other occasions with extremely high fire protection requirements.

Advantages and Disadvantages of 94V0 Control Board

The advantages and disadvantages of 94V0 control board are analyzed as follows:

Advantage:

- Excellent Fire Resistance: The 94V0 control panel meets the highest rating of V-0 in the UL94 standard, which means it has extremely low flammability and smoke production. In the event of a fire, this control panel can quickly self-extinguish, effectively reducing the risk of fire.

- High heat resistance: 94V0 grade raw materials can withstand high temperatures up to 1050°C, allowing the control board to maintain stable performance in extreme working environments.

- Wide range of applications: Due to its excellent fire resistance and high heat resistance, 94V0 control boards are widely used in situations with extremely high fire protection requirements, such as servers, data centers, industrial equipment, medical equipment, Aerospace and other fields.

- Good electrical performance: 94V0 control boards usually have excellent electrical performance and can meet the needs of various complex electronic systems.

Disadvantages:

- Higher cost: Since the 94V0 control board uses high-standard fireproof materials and manufacturing processes, its cost is usually higher. This may increase the overall cost of the product and affect market competitiveness.

- Higher manufacturing difficulty: To meet the requirements of UL94 V-0 level, the quality of each link in the manufacturing process needs to be strictly controlled. This can increase the difficulty and complexity of manufacturing.

- Weight and Volume: Due to the use of high-density fireproof materials and reinforced structures, the 94V0 control panel may be heavier and larger than other types of control panels. This may pose certain challenges to the design and layout of the product.

- Weather Resistance Limitation: Although the 94V0 control board has high heat resistance, its performance may be affected under extreme climate conditions (such as extremely cold or extremely hot environments).

To sum up, the 94V0 control board has significant advantages in fire protection performance, heat resistance, electrical performance, etc., but there are also challenges in cost, manufacturing difficulty, weight and volume, and weather resistance.

When choosing to use the 94V0 control board, you need to comprehensively consider its advantages and disadvantages as well as the needs of specific application scenarios.

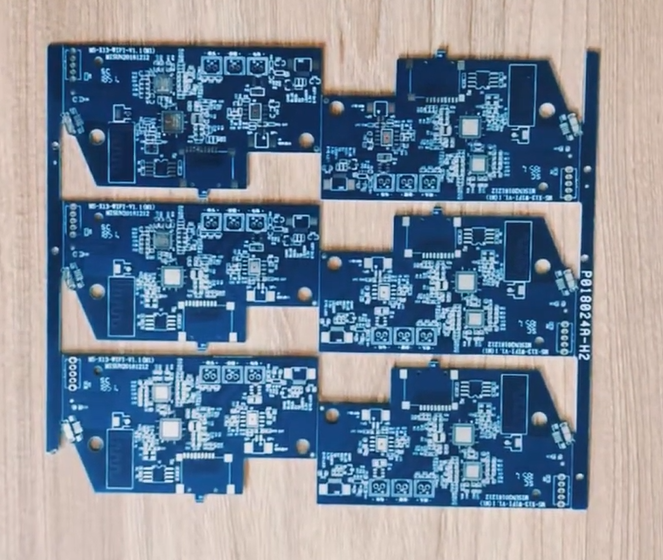

Manufacturing process of 94V0 control board

The manufacturing process of 94V0 control board involves multiple links, including raw material selection, circuit design, plate cutting, drilling, welding, testing, etc. During the manufacturing process, the quality of each link needs to be strictly controlled to ensure that the performance of the final product reaches the UL94 V-0 level requirements.

- Raw material selection: Selecting raw materials that meet the requirements of UL94 V-0 level is the first step in the manufacturing process. These raw materials often have excellent fire resistance, heat resistance and electrical properties.

- Circuit Design: According to the functional requirements and fire protection requirements of the product, designing a reasonable circuit diagram is the key to the manufacturing process. Circuit design needs to take into account signal transmission, power distribution, heat dissipation and other factors.

- Board Cutting and Drilling: Cut the raw materials into appropriate sizes and drill holes to install electronic components. In this process, it is necessary to ensure the accuracy of dimensions and hole position.

- Soldering: Solder the electronic components to the control board. The welding process requires control of temperature and time to avoid welding defects and affecting fire performance.

- Testing: After completing the welding, the control board needs to be tested in detail to ensure that its functionality and fire resistance meet the requirements. Testing includes electrical performance testing, temperature resistance testing, fire performance testing, etc.

Application fields of 94V0 control board

Due to its excellent fire resistance, 94V0 control panels are widely used in various fields.

- Servers and Data Centers: In these settings, equipment needs to operate for long periods of time and withstand high temperatures and fire risks. Using the 94V0 control panel can significantly reduce the risk of fire and ensure the safe operation of the equipment.

- Industrial Equipment: In industrial production, many equipment need to withstand harsh environments such as high temperature, moisture, and dust. Using the 94V0 control board can improve the stability and reliability of the equipment.

- Medical Equipment: The safety and reliability of medical equipment are crucial to the life and health of patients. Using the 94V0 control panel ensures that medical equipment can still work properly in emergencies such as fires.

- Aerospace: In the aerospace field, the requirements for the fireproof performance of materials are extremely high. 94V0 control board is widely used in the manufacturing of aircraft, rockets and other aerospace vehicles due to its excellent fire resistance.

- Energy and Infrastructure: In infrastructure such as electricity, oil, and natural gas, the safe operation of equipment is crucial to ensuring energy supply and social stability. 94V0 control panels are also widely used in these fields to ensure that equipment can still work normally in emergencies such as fires.

- Communication and network equipment: Communication and network equipment need to operate 24 hours a day and are usually deployed in densely populated areas. Using the 94V0 control panel can ensure that these devices can still work normally in emergencies such as fires, thereby ensuring the smooth flow of communications and networks.

In short, the 94V0 control board has been widely used in situations that need to withstand harsh environments such as high temperature, humidity, dust, or face the risk of fire to ensure the safe and stable operation of the equipment.

94v-0 led circuit board

94V-0 LED circuit board is a circuit board that complies with the V-0 level in the UL94 standard and is specially used for LED lighting products. Since LED lighting products generate a certain amount of heat during operation, circuit boards with high temperature tolerance and fire resistance are required to ensure the safety and stability of the product.

94V-0 LED circuit board is manufactured using special flame retardant materials and processes, with excellent fire resistance and heat resistance. It can withstand high temperatures and flames and is not easy to burn or produce harmful gases, thereby ensuring the safety of LED lighting products during use.

In addition, the 94V-0 LED circuit board also has good electrical performance and stability, which can ensure the normal operation of LED lighting products. It uses high-quality electronic components and advanced production technology to ensure the performance and reliability of the circuit board and improve the service life and stability of LED lighting products.

Therefore, choosing an LED circuit board that meets the 94V-0 standard is an important guarantee for ensuring the safe, stable and efficient operation of LED lighting products. When purchasing LED lighting products, consumers are advised to pay attention to whether the circuit boards used in the products comply with the 94V-0 standard, and choose products with well-known brands and quality assurance.

What are the safety standards for 94VO control board

The safety standard of the 94V0 control panel means that it meets the V-0 level requirements of the UL94 standard. UL94 is an internationally widely used flammability performance evaluation standard for plastic materials. The V-0 level is the highest level in the UL94 standard, which means the material has the lowest flammability and smoke production.

Specifically, the safety standards of the 94V0 control panel include the following aspects:

- Combustion Performance: The 94V0 control panel has extremely low flammability in flame tests. When the sample is affected by an external fire source, it will extinguish itself in a short period of time and will not continue to burn. In addition, the amount of smoke produced during the combustion process is also extremely low, helping to reduce reduced visibility and the risk of suffocation in a fire.

- Heat resistance: The raw materials used in the 94V0 control board can withstand high temperatures up to 1050°C, which means that it can maintain stable performance in extreme working environments and is not prone to deformation or failure.

- Environmental protection requirements: The use of hazardous substances needs to be strictly controlled during the production process of the 94V0 control panel to meet relevant environmental regulations and standards. For example, it cannot contain too many toxic substances to avoid causing harm to the human body and the environment.

- Safety Certification: In order to prove that the product complies with relevant safety standards, 94V0 control boards usually need to be certified and tested by authoritative organizations. These certifications and tests include UL certification, CE certification, etc. to ensure product safety and reliability.

In short, the safety standards of the 94V0 control board are to ensure that it can maintain stable performance and safety in various harsh environments and emergency situations. These standards cover combustion performance, heat resistance, environmental requirements, and safety certification to ensure product quality and reliability.

What is the production process of 94V-0 control board?

The production process of 94V-0 control board usually includes the following steps

- Material selection and procurement: Select raw materials that meet the UL 94V-0 flame retardant grade standard, such as substrates, electronic components, etc.

- Circuit design and production: Design the circuit according to product requirements, and then transfer the circuit pattern to the substrate.

- Component welding and assembly: Weld electronic components to the circuit board and perform necessary assembly work.

- Quality inspection and testing: Conduct quality inspection on the produced control boards, including appearance inspection, electrical performance testing, flame retardant performance testing, etc.

- Packaging and shipping: After passing the quality inspection control panel, the products are packaged and then shipped to the customer.

What should we pay attention to when using the 94V-0 control panel?

When using the 94V-0 control board, you need to pay attention to the following points:

- Avoid high temperature environments: Although the 94V-0 control board has good flame retardant properties, long-term exposure to high temperatures should still be avoided to avoid affecting its performance and safety.

- Regular inspection and maintenance: Regular inspection and maintenance of the control panel to ensure its normal operation and timely discovery of potential safety hazards.

- Follow the operating specifications: When using the control panel, you should follow the relevant operating specifications and safety requirements to avoid safety accidents caused by misoperation or improper use.

How to deal with control panels that do not meet the requirements of 94V-0 class?

If it is found that the control panel does not meet the 94V-0 level requirements, it should be stopped immediately and the following measures should be taken:

- Communicate with suppliers: Communicate with the control panel supplier to understand whether it meets the 94V-0 level requirements, and request a control panel that meets the standard.

- Replace the control board: If the supplier cannot provide a control board that meets the requirements of 94V-0 level, you should consider replacing the control board with another supplier or model.

- Strengthen quality management: For purchased control boards that do not meet the requirements of 94V-0 level, quality management should be strengthened to ensure that they are used within a safe and controllable range.

What is the future development trend of 94V-0 control board?

With the continuous advancement of technology and people’s increasing requirements for product safety, the future development trend of 94V-0 control boards may be manifested in the following aspects:

- Material innovation: Continuously develop new flame-retardant materials to improve the flame-retardant performance and safety of control panels.

- Intelligence and integration: Apply more intelligence and integration technologies to the control panel to improve its performance and reliability.

- Green and environmental protection: Pay attention to environmental protection and sustainable development, and promote the development of control panels in the direction of green and environmental protection.

- Customization and personalization: Meet the customized needs of different industries and customers, and provide more personalized and diversified control panel products.

What is the difference between 94VO control panel and MC control board?

There are obvious differences in design and application between the 94V0 control panel and the MC control panel.

First of all, the 94V0 control panel is a control panel manufactured according to the V-0 level in the UL94 standard. Its main features are excellent fire resistance and high heat resistance.

This kind of control panel is widely used in situations with extremely high fire protection requirements, such as servers, data centers, industrial equipment, medical equipment, aerospace and other fields. The main goal of the 94V0 control panel is to ensure that the equipment can still work normally during emergencies such as fire, thereby protecting the safety of personnel and equipment.

The MC control board, such as MC-BOARD, is a control board dedicated to specific applications. For example, the MC-BOARD motherboard is designed for use in laser engraving/cutting motion control systems.

It supports motion control of four axes, including linkage control of the X/Y axes and jog control of the Z/U axes. This control board is optimized for specific industrial applications, providing efficient motion control and precise positioning capabilities.

In addition, MC control board can also refer to other control boards with specific functions and uses, such as MC810 lifting electromagnet thyristor control board. This control board is specially used for electromagnet control occasions. It uses a 32-bit industrial-grade high-performance microprocessor and has functions such as fault alarm, interface parameter display, and automatic storage of set parameters.

It is suitable for controlling the excitation or demagnetization process of lifting electromagnets, and achieves precise control of the electromagnets through three-phase fully controlled bridge rectification and single-phase fully controlled bridge rectification.

To sum up, the main difference between the 94V0 control board and the MC control board lies in their design goals and application scenarios. The 94V0 control board focuses on fire resistance and heat resistance, and is suitable for occasions with extremely high safety requirements; while the MC control board is designed and optimized according to specific industrial application requirements, providing efficient motion control, electromagnet control and other functions.

Summarize

The 94V0 control panel is an electronic control panel that complies with the V-0 level in the UL94 standard and has the characteristics of extremely low flammability, low smoke generation and high heat resistance.

It is widely used in servers, data centers, industrial equipment, medical equipment, aerospace and other fields, as well as other occasions with extremely high fire protection requirements.

During the manufacturing process, the quality of each link needs to be strictly controlled to ensure that the performance of the final product reaches the UL94 V-0 level requirements. By using the 94V0 control panel, the risk of fire can be significantly reduced and the safety and reliability of the equipment improved.

94v 0 Control Board FAQs

94V-0 control panel refers to a control panel made of materials that meet the UL 94V-0 flame retardant grade standard. This type of control panel is often used in electronic equipment to ensure that the control panel does not cause a fire in the event of a malfunction or short circuit in the equipment.

The main difference between the 94V-0 control panel and ordinary control panels is the materials used. The 94V-0 control panel is made of materials with better flame retardant properties, which can maintain a lower risk of burning under high temperatures or short circuit conditions. Ordinary control panels may use materials that have not been tested for flame retardant ratings, and their combustion performance may be poor.

To determine whether a control panel meets the 94V-0 rating, you can check the UL certification report or flame retardant rating test report provided by its material supplier. In addition, some control panel manufacturers will also mark 94V-0 level information on their products for consumers’ reference.

The main reason for choosing a 94V-0 level control panel is to ensure the safety and reliability of the product. In electronic equipment, the control board is one of the core components and is responsible for the operation and control of the equipment. If the material used for the control panel has poor flame retardant properties, once the equipment fails or short-circuit, it is easy to cause a fire, causing serious consequences. Therefore, choosing a control panel that meets the 94V-0 level standard can effectively reduce this risk.

To ensure the quality of the 94V-0 control board, you first need to choose a reputable material supplier and manufacturer. In addition, product quality inspections and tests should be carried out regularly to ensure that the control panel meets relevant standards and requirements. At the same time, the use of materials that meet the UL 94V-0 flame retardant rating standard is also the key to ensuring the quality of the control board.

94V-0 control board is widely used in many fields due to its excellent flame retardant performance. Especially in the fields of electronics, communications, home appliances, automobiles, aerospace and other fields where product safety and reliability are extremely high, 94V-0 control boards have been widely used. For example, 94V-0 control boards can be seen in communication equipment, computers, medical equipment, and industrial automation control systems.