Assemble electronic components on LED PCB board

Assemble the electronic components on the LED PCB board, ensuring they are accurately positioned and securely connected together to form a reliable and high-performance LED lighting system.

This process requires delicate operating skills and strict quality control to ensure the long-term stability and reliability of the product.

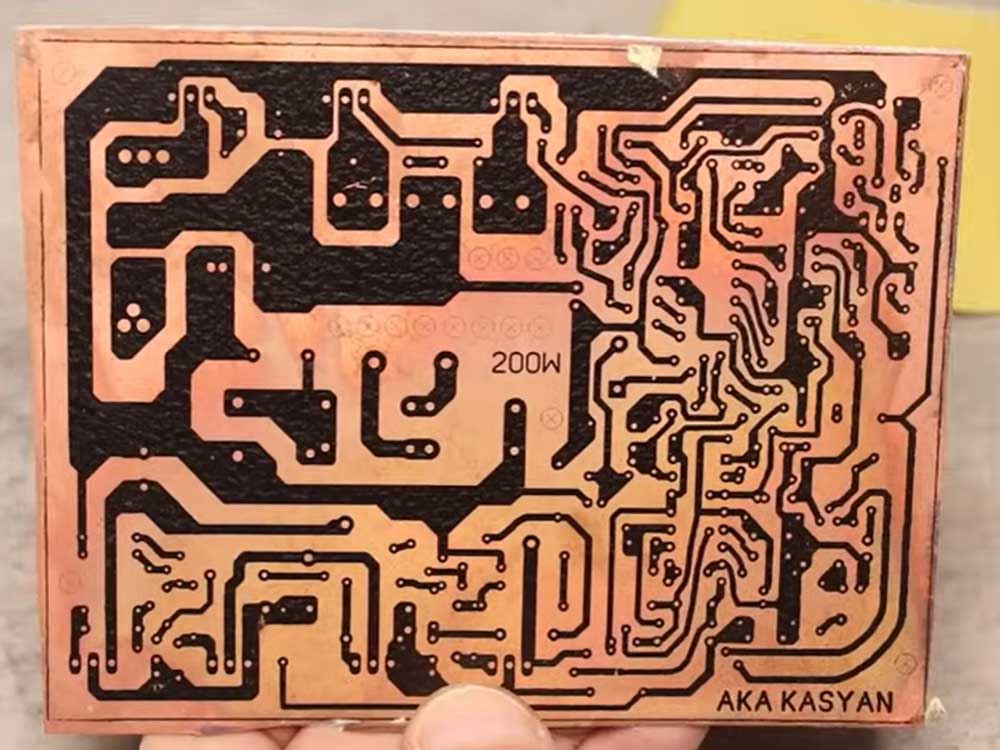

LED PCB board introduction

LED PCB board, also known as LED light board or LED circuit board, is an important electronic component, mainly used to connect LED lamp beads with circuits to achieve lighting, display or other functions. LED PCB boards are usually made of insulating materials, such as FR4 or aluminum substrates, with conductive lines and mounting locations for LED lamp beads designed on them.

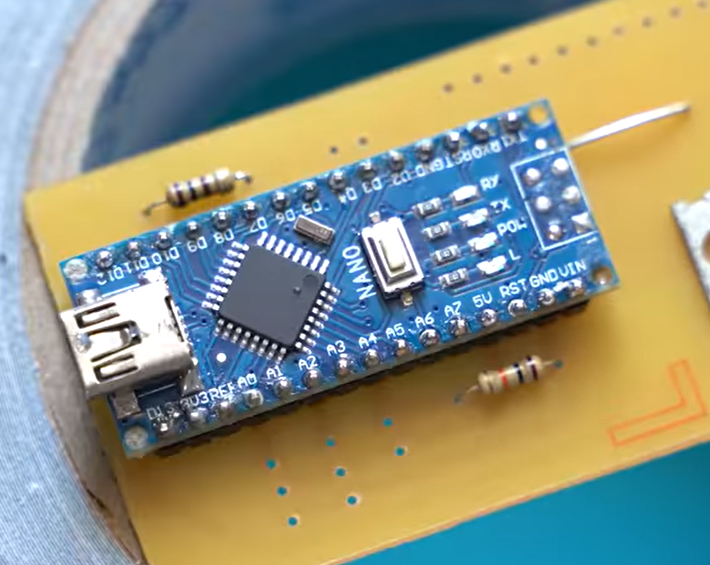

Types and selection of electronic components

Electronic components are the basic units that constitute electronic products, including resistors, capacitors, inductors, diodes, transistors, ICs, etc. In LED PCB boards, the following components are usually required:

- LED lamp beads: used to generate light and are the core components of LED PCB boards.

- Resistor: used to limit current and protect LED lamp beads from overcurrent damage.

- Capacitor: used for filtering and decoupling to improve circuit stability.

- Diode: used for rectification to ensure that the LED lamp beads work at the correct voltage.

- IC: used to control circuit functions, such as driver IC, etc.

Choosing the right electronic components is crucial to the performance of the LED PCB board. The selection needs to be based on specific application requirements, working voltage, current, working environment temperature and other factors.

Assembly process of electronic components

- Component inspection: Ensure that all components are intact and specifications meet design requirements.

- PCB board cleaning: Use alcohol or cleaning agent to remove dirt and grease on the surface of the PCB board.

- Apply flux: Apply an appropriate amount of flux on the PCB board wires that need to be welded.

- Component placement: According to the design requirements, place the electronic components on the PCB board in the correct direction and position.

- Welding: Use a soldering iron or a hot air gun to weld the components to the PCB board to ensure reliable welding quality.

- Solder joint inspection: Check whether all solder joints are full and there are no empty solder joints or continuous solder joints.

- Assembly quality inspection: Carry out functional testing and appearance inspection to ensure that the assembly quality meets the requirements.

- Finished product packaging: Pack the qualified LED PCB boards for transportation and storage.

Things to note when assembling electronic components on LED PCB boards

- During the welding process, the welding temperature and time must be controlled to avoid thermal damage to LED lamp beads and other components.

- When welding, pay attention to the quality of the solder joints to avoid false soldering, continuous soldering, etc., which will affect the continuity and reliability of the circuit.

- Keep it clean during the assembly process to avoid dust, dirt and other impurities from entering the inside of the PCB board and affecting the normal operation of the circuit.

- Some sensitive components, such as ICs, crystal oscillators, etc., need to be handled with special care to avoid being affected by excessive mechanical stress or static electricity.

- After assembly is completed, comprehensive quality inspection is required to ensure that the performance and reliability of the product meet the requirements.

LED PCB board electronic component assembly summary

Assembling electronic components on an LED PCB is a process that requires professional skills and experience. In order to ensure the quality and reliability of the product, it is necessary to select appropriate components, follow the correct assembly process, and pay attention to various precautions. Through continuous learning and practice, we can improve our skill levels and contribute to the production of high-quality LED PCB boards.