What is a glass glaze film resistor

Glass glaze film resistors, also known as glass glaze resistors, cermet resistors or thick film resistors, are a special type of resistor.

It is made by mixing the oxides (such as palladium oxide, ruthenium oxide, etc.) powder of precious metal silver, palladium, rhodium, ruthenium, etc. It is coated on the ceramic silicon substrate by screen printing method and sintered at high temperature.

Glass glaze resistors have a wide resistance range, relatively low price, small temperature coefficient, good moisture resistance, and good stability. In addition, it has a large rated power, low noise, good high-frequency characteristics, small size and light weight. The resistance range is 4.7Ω – 200MΩ, the rated power is generally 1/8W, 1/4W, I I2 W, lW, 2W, and the high power type is 500W.

In circuits, the name of glass glaze resistors is generally “R” or “RI”.

Glass glaze resistors are precision components mainly used in electronic equipment, such as electron tubes, radios, televisions, etc. In terms of appearance and structure, there are two common forms: cylindrical and flaky.

How does a glass glaze film resistor work

The working principle of glass glaze film resistors is based on Ohm’s law, that is, at a certain voltage, the current is proportional to the resistance. The resistance of a resistor is generated by the resistance of the resistive material inside it to the current flow. For glass glaze film resistors, its resistance is achieved by coating a glass glaze film on a ceramic substrate and controlling the thickness and composition of the film.

When electric current flows through a glass glaze film resistor, the electrons are hindered by the resistive material, thereby generating heat energy. This power conversion can be expressed by the formula P=VI or P=I²R, where P represents power, V represents voltage, I represents current, and R represents resistance.

Glass glaze film resistors have a wide resistance range and have good stability and reliability. Its temperature coefficient is small, that is, the resistance changes little with temperature, so it is suitable for circuits that need to work stably in different temperature environments. In addition, glass glaze film resistors also have high moisture resistance and corrosion resistance, and can maintain stable performance in harsh environments.

Design principles of glass glaze film resistors

The design principle of glass glaze film resistors is based on the inherent resistance characteristics of the material and Ohm’s law. A resistor is a passive electronic component used to limit the flow of current or reduce voltage.

Glass glaze film resistors are made of special materials. Metal oxides, metal powders and glass glazes are usually mixed to form a resistance slurry, and then the resistance slurry is coated on the insulating substrate through processes such as screen printing. And it is sintered at high temperature to form a hard resistor body.

The core design principles of glass glaze film resistors include the following points:

- Selection of resistance material: The resistance material of glass glaze film resistor is usually composed of metal oxide, metal powder and glass glaze. These materials have good electrical conductivity and stability, providing stable resistance values.

- Determination of resistance value: The resistance value of glass glaze film resistor is achieved by controlling the ratio of resistive materials and the size of the resistor body. According to Ohm’s law, the resistance value is related to the length, cross-sectional area of the resistor and the resistivity of the material. By adjusting these factors, the desired resistance value can be obtained.

- Formation of insulating protective layer: In order to protect the resistor and provide insulation function, glass glaze is coated on the surface of the resistor to form a hard protective layer. This protective layer not only provides good insulation properties, but also increases the mechanical strength and stability of the resistor.

When electricity passes through a glass glaze film resistor, the electrons are blocked by the resistive material, creating heat. The power dissipation capability of a resistor depends on its material and design, ensuring that its power rating is not exceeded under normal operating conditions to maintain stable resistance value and long-term reliability.

It should be noted that the above is only a brief introduction to the design principles of glass glaze film resistors. The actual design process may involve more details and complex process steps, which need to be considered and optimized based on specific application requirements.

Glass glaze film resistor circuit diagram

Material composition of glass glaze film resistor

The material composition of glass glaze film resistors mainly includes the following parts:

- Metal oxide: Glass glaze film resistors use oxides of precious metals such as silver, palladium, rhodium, etc. as conductive materials. These metal oxides conduct electricity and generate heat in resistors.

- Glass glaze: Glass glaze is a special glassy substance composed of oxides, borates, silicates, etc. It serves as the dielectric material of the resistor and plays the role of insulating, protecting and fixing the resistance wire.

- Organic binder: Organic binder is a substance used to mix metal oxide and glass glaze into a slurry. It gives the resistor slurry the appropriate viscosity and fluidity for easy coating and sintering to form a film.

- Skeleton: The skeleton is a structural member that supports the resistive film layer. It is usually made of insulating materials, such as ceramics, glass, etc. The shape and size of the bobbin determines the shape and size of the resistor.

- Screen printing method: Screen printing method is a process method that prints resistor paste onto the skeleton. By controlling the thickness and accuracy of printing, resistors with high precision and good stability can be produced.

After undergoing precise processing, these materials are combined to form a glass glaze film resistor. Its resistance range, accuracy, temperature coefficient and other parameters can be adjusted and optimized as needed.

What is the accuracy level of glass glaze film resistors

There is no fixed standard for the accuracy level of glass glaze film resistors, but is determined based on the specific product and manufacturing process. Generally speaking, glass glaze film resistors can achieve relatively high accuracy levels, such as ±1%, ±2% or higher. However, the exact level of accuracy depends on the manufacturer’s product specifications and manufacturing processes.

When selecting glass glaze film resistors, the required accuracy level should be determined based on the specific application needs. For circuits that require precise measurements, resistors with higher accuracy grades should be selected to ensure measurement accuracy.

What are the models and specifications of glass glaze film resistors

There are many types and specifications of glass glaze film resistors, and different manufacturers may have different naming and specification standards. The following are the models and specifications of some common glass glaze film resistors:

- Model naming: The model number of a glass glaze film resistor usually consists of letters and numbers, which are used to indicate the type, size, resistance, accuracy and other characteristics of the resistor. For example, a model might be named “RX70-10M-1%,” where “RX70” indicates the series or type of resistor, “10M” indicates a resistance of 10 megaohms, and “1%” indicates the accuracy level.

- Resistance range: The resistance range of glass glaze film resistors is very wide, ranging from a few ohms to hundreds of megaohms. Common resistance ranges include 5.1 ohms to 200 megohms, or even wider.

- Rated power: Rated power refers to the maximum power that a resistor can sustain continuously under normal operating conditions. Glass glaze film resistors generally have a power rating of 0.05W to 2W, but there are some high-power models with power ratings of up to 500W or higher.

- Accuracy level: The accuracy level indicates the accuracy of the resistor resistance value. Common accuracy levels include ±1%, ±2%, ±5%, etc. High-precision glass glaze film resistors are commonly used in circuits where precise measurements are required.

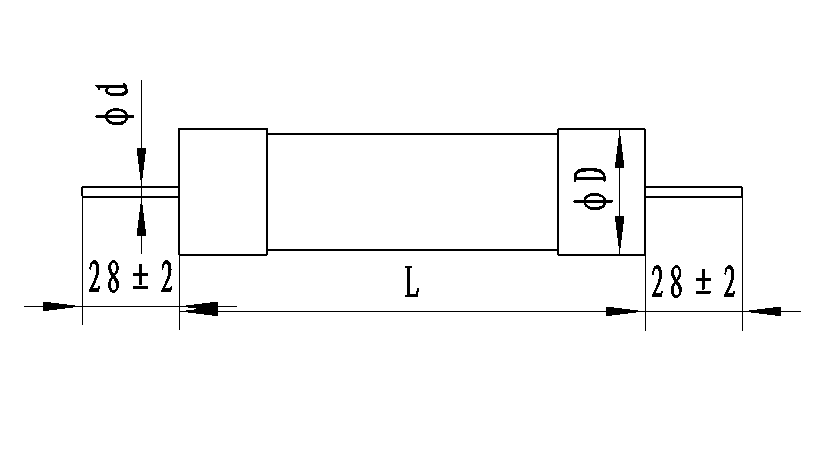

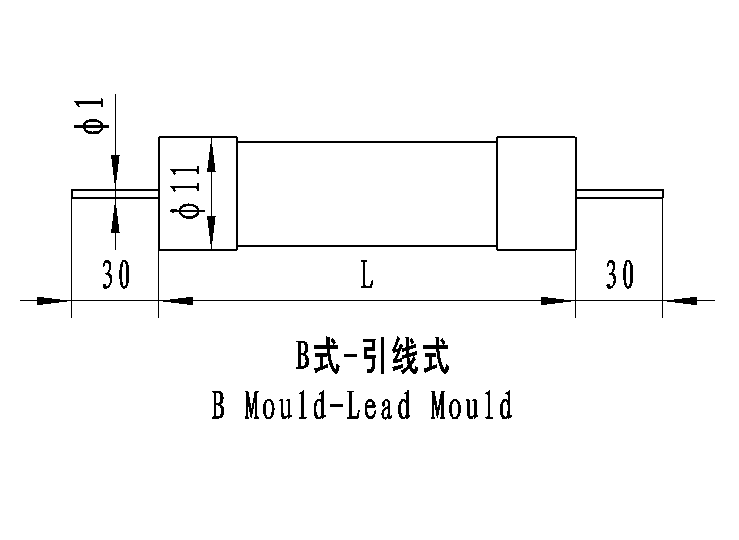

- Size and packaging: The size and packaging form of glass glaze film resistors vary depending on the manufacturer and application scenario. Common packaging forms include cylindrical, sheet, tubular, etc., and the size is determined according to specific needs.

It should be noted that the above are just some common models and specifications of glass glaze film resistors, and actual selection needs to be considered based on specific application requirements.

In addition, different manufacturers may have different model naming and specification standards, so you should refer to the technical documentation provided by the manufacturer or consult the relevant sales staff when choosing.

Example of glass glaze film resistor: RI40A glass glaze film high voltage resistor

The RI40A glass glaze high-voltage resistor 5W10KJ manufactured by a Chinese electronic component manufacturer is used in photovoltaic industry equipment. It is often used in inverter circuit boards. It is characterized by high power, high voltage resistance and stable resistance value.

If you need to obtain specific RI40A glass glaze film high voltage resistor technical documentation or product specifications, please contact us.

What are the advantages of glass glaze film resistors

Glass glaze film resistors have the following advantages:

Good high-temperature stability

The working temperature of glass glaze resistors can reach over 300°C. At the same time, its resistance value basically remains unchanged in high-temperature environments, making it suitable for some high-temperature application scenarios.

Strong corrosion resistance

Glass glaze resistors have good chemical stability and are not easily corroded by chemicals such as acids and alkalis.

Good precision

The resistance value of glass glaze resistor has high precision and small error, so it is suitable for circuits with high precision requirements.

Excellent insulation properties

Glass glaze resistors have good insulation properties and can be used in high-voltage environments.

Small size and light weight

Glass glaze resistors are small and lightweight, making them easy to install by press-fitting and wiring.

Non-inductive, high power

Glass glaze high voltage resistors have the characteristics of non-inductive, high power, high voltage resistance, pulse resistance, high and low temperature resistance, low temperature coefficient, high frequency, stable resistance, small size, high power, low noise, etc. Advantage.

Large resistance range

The resistance range of glass glaze film resistors is relatively large, which can meet the needs of different circuits.

Low noise

It has certain advantages in terms of accuracy of measurement and use.

Overall, the advantages of glass glaze film resistors include good stability, high accuracy and reliability, and a wide range of applications. Therefore, they become an indispensable component in many electronic devices.

What are the disadvantages of glass glaze film resistors

The main disadvantages of glass glaze film resistors include:

Resistance range limitation

Glass glaze film resistors usually cannot provide resistance values below 1KΩ, which may limit their use in certain low resistance applications.

Large temperature coefficient

Although glass glaze film resistors have good high-temperature stability, their temperature coefficients are relatively large, that is, the resistance value will change greatly with changes in temperature. This may have an impact on some applications that require higher temperature stability.

Higher cost

Glass glaze film resistors are more expensive to manufacture than some other types of resistors. This is mainly due to the higher cost of its production process and materials used.

Long-term stability issues

When the working voltage is exceeded for a long time or there is infiltration of external moisture, the glass glaze film resistor may suffer from electrical corrosion, causing the film to gradually peel off and increase the resistance value or damage it. Therefore, you need to pay attention to keep it dry when using it and avoid exceeding the working voltage for a long time.

It should be noted that the above shortcomings are not common to all glass glaze film resistors, and users should weigh and consider them based on specific needs and scenarios when choosing.

At the same time, with the advancement of technology and improvements in manufacturing processes, the shortcomings of some glass glaze film resistors may be improved and optimized to a certain extent.

What is the difference between glass glaze film resistors and other resistors

The main differences between glass glaze film resistors and other resistors are reflected in the following aspects:

- Materials and processes: The main materials for making glass glaze resistors are molybdenum and glass glaze. The production process is relatively complex, including preparation of molybdenum film, printing insulating layer, aluminum wire connection and glass glaze sintering. Ordinary resistors are usually made of carbon, ferrite, alloy and other materials, and the production process is relatively simple. It usually only needs to be sprayed with carbon film or coated with alloy resistance wires.

- Electrical properties: Glass glaze resistors have relatively higher temperature resistance and can withstand temperatures up to 400°C, while ordinary resistors have lower temperature resistance and can usually only be used at around 100°C. In addition, glass glaze resistors also have better corrosion resistance than ordinary resistors. This is mainly due to the fact that glass glaze has excellent acid resistance, alkali resistance, oxidation resistance, moisture resistance and electrical insulation properties, and can operate in harsh environments for a long time.

- Usage environment: Glass glaze resistors are mainly used in ordinary electronic equipment. The working temperature they can withstand is generally -55℃~+125℃, and they can be used in dry and humid environments. Ceramic resistors can withstand higher operating temperatures, generally +155°C to +375°C, and are suitable for use in various high-temperature, high-precision electronic equipment.

- Structure: The glass glaze resistor with higher power is a wire-wound resistor. The center of the magnetic tube is hollow, while the center of the magnetic tube of ordinary resistors is solid.

According to the above description, it can be seen that there are obvious differences between glass glaze film resistors and other resistors in terms of materials, processes, electrical properties, use environment and structure. These differences give glass glaze film resistors unique advantages in certain applications.

Which is more durable, glass glaze film resistor or ordinary resistor

The durability of glass glaze film resistors and ordinary resistors varies depending on the specific use environment and conditions, and it is impossible to generalize which one is more durable. However, from the perspective of temperature resistance, glass glaze resistors have higher temperature resistance than ordinary resistors and can withstand temperatures up to 400°C. This means that glass glaze resistors may be more durable than ordinary resistors in high temperature environments.

However, it should be noted that the durability of the resistor is also affected by other factors, such as usage environment, operating voltage, current, etc. Therefore, when selecting a resistor, comprehensive consideration should be given to the specific application scenarios and needs to select the most suitable resistor type.

Additionally, as with any type of resistor, proper use and maintenance are also important factors in ensuring its durability.

The manufacturer’s instructions and recommendations should be followed to avoid exceeding the rated operating conditions of the resistor to ensure its long-term stable operation.

Which one is more expensive, glass glaze film resistor or ordinary resistor

The prices of glass glaze film resistors and ordinary resistors vary depending on many factors such as brand, specifications, market demand and supply, so it is impossible to generalize which one is more expensive.

Generally speaking, glass glaze film resistors have higher accuracy, stability and temperature resistance than ordinary resistors. Therefore, in some application scenarios that require higher resistance performance, glass glaze film resistors may be better than ordinary resistors. The price is more expensive.

However, in some conventional application scenarios, the demand for ordinary resistors is greater, and production and supply are relatively sufficient, so the price may be more affordable.

When actually purchasing electronic components, the specific price needs to be comprehensively considered based on various factors such as brand, specifications, market demand and supply.

When selecting resistors, it is recommended to choose according to specific application scenarios and needs to achieve the best cost-effectiveness.

What are the application ranges of glass glaze film resistors

Glass glaze film resistors have a wide range of applications, mainly including the following aspects:

- Electronic products: Glass glaze film resistors are often used in circuit boards in electronic products, such as consumer electronics such as mobile phones, televisions, and computers, to limit the flow of current and reduce voltage.

- Power equipment: In power equipment, such as transformers, generators and transmission lines, glass glaze film resistors also play an important role in stabilizing current and distributing voltage.

- Sensors: Glass glaze film resistors are also used in sensors. For example, temperature sensors and photoelectric sensors require resistors to achieve accurate measurement of circuits.

In addition, due to its high precision, low noise, low temperature drift, high durability, good stability and high temperature resistance, glass glaze film resistors are also widely used in various precision electronic instruments, circuit boards and other applications that require high precision and high temperature resistance. In the case of stability resistance.

In what scenarios is it better to use glass glaze film resistors than ceramic resistors

Glass glaze film resistors and ceramic resistors each have their application scenarios, but the following are some recommended usage scenarios, among which glass glaze film resistors may have more advantages:

- High temperature environment: Glass glaze resistors have good temperature resistance and can withstand temperatures up to 400°C. Therefore, glass glaze resistors may be more durable than ceramic resistors in high temperature environments.

- Harsh environment: Glass glaze resistors have good corrosion resistance and oxidation resistance, and can be used in harsh environmental conditions, such as moisture, acid and alkali, etc.

- High precision requirements: Glass glaze resistors have high precision and stability and are suitable for circuits with high precision requirements.

- High voltage and current: Glass glaze resistors have the ability to withstand high voltage and current, and are suitable for high power and high current application scenarios.

According to the above advantages of glass glaze film resistors, glass glaze film resistors may have more advantages in application scenarios with high temperature environments, harsh environments, high precision requirements, and high voltage and current. However, the specific choice should be comprehensively considered based on specific needs and application scenarios.

How to find a glass glaze film resistor distributor or manufacturer

There are several ways to find a distributor or manufacturer of glass glaze film resistors:

- Electronic component distributor websites: Many electronic component distributors have their own websites where you can search for glass glaze film resistors and filter out the distributors or manufacturers that meet your needs. Some well-known electronic component distributors include DigiKey, Mouser, Arrow, etc.

- Electronic market: In some electronic markets, such as Shenzhen Huaqiangbei Electronic Market, you can find a large number of electronic component suppliers, including manufacturers and distributors of glass glaze film resistors. You can obtain relevant information through on-site visits or online inquiries.

- Professional exhibitions: Participate in professional exhibitions in the electronics industry, such as China Electronics Show, etc., where you can communicate face-to-face with many electronic component manufacturers and distributors, learn about their products and services, and find glass glaze film resistor suppliers that meet your needs. business.

- Ask professionals: If you have relevant connections or friends in the electronics industry, you can consult them to see if they have recommendations for suitable glass glaze film resistor suppliers.

When looking for suppliers, it is recommended that you pay attention to the following points:

- Understand the credibility and reputation of suppliers and choose suppliers with good reputation;

- Understand the supplier’s product quality and after-sales service, and choose suppliers who can provide high-quality products and services;

- Understand supplier prices and delivery times and choose the supplier that can meet your needs.

Hopefully this information will help you find the right distributor or manufacturer of glass glaze film resistors.

Of course you can contact us. We are an electronic component distributor and supplier in China. We have various electronic component brand products and have long-term cooperation with global electronic component manufacturers.