Method for manufacturing base metal glass glaze resistor slurry for potentiometers

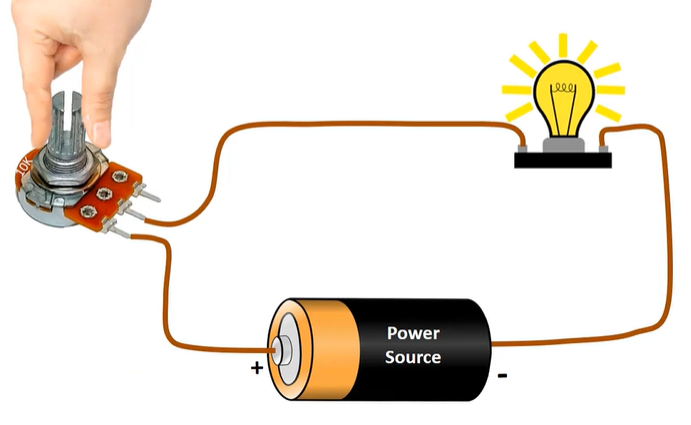

A potentiometer is an adjustable electronic component widely used in electronic equipment. Base metal glass glaze resistor slurry is an important material in potentiometer manufacturing, and its performance directly affects the quality and stability of the potentiometer.

This article will introduce in detail the manufacturing method of base metal glass glaze resistor slurry for potentiometers, including raw material selection, batching, mixing, grinding, modulation, filtration, inspection and packaging.

Raw material selection

- Base metal powder: Choose base metal powder with high purity, uniform particle size and stable resistivity, such as nickel, chromium, copper, etc. These metals have good electrical conductivity and stability and can meet the requirements of potentiometers.

- Glass glaze: Glass glaze is an inorganic non-metallic material with high temperature stability, chemical stability and good insulation properties. To select a glass glaze suitable for potentiometers, it is required that its composition has good compatibility with the base metal powder and can form a dense resistive film during the sintering process.

- Organic carrier: Organic carrier is an important component of resistor slurry, which plays the role of dispersing metal powder and glass glaze and adjusting the viscosity of the slurry. Choose organic carriers with moderate volatility and good environmental performance, such as terpineol, butyl carbitol, etc.

Ingredients

Base metal powder, glass glaze and organic carrier are mixed according to a certain proportion. The proportion of ingredients is adjusted according to the performance requirements and manufacturing process of the potentiometer.

Generally speaking, the higher the content of base metal powder, the lower the resistivity; the higher the content of glass glaze, the higher the resistivity.

mix

Put the prepared raw materials into the mixing equipment and mix them so that the base metal powder, glass glaze and organic carrier are fully and evenly mixed together. The mixing time and speed should be moderate to avoid agglomeration of metal powder and excessively large glass glaze particles.

Grind

The mixed slurry needs to be ground to reduce the particle size and improve the fineness and uniformity of the slurry. Grinding equipment can use ball mills, sand mills, etc. During the grinding process, the grinding time and the type and quantity of grinding media should be controlled to avoid excessive grinding that will lead to a decrease in slurry performance.

modulation

The ground slurry needs to be modulated to adjust the viscosity and fluidity of the slurry. Appropriate amounts of diluents, thickeners and other auxiliary materials can be added during the preparation process. The prepared slurry should have good brushability and adhesion to form a uniform resistance film on the potentiometer substrate.

filter

The prepared slurry needs to be filtered to remove impurities and particles. Filtration equipment can use wire mesh filters, filter cloth filters, etc. The filtered slurry should be clean and free of impurities to ensure the quality and stability of the potentiometer.

test

Conduct quality inspection on the filtered slurry, including appearance, viscosity, fineness, solid content, resistivity and other indicators. Only the slurry that has passed the inspection can be packaged and used. Unqualified slurry needs to readjust the proportion of ingredients or undergo other processing until it meets the quality requirements.

Package

The slurry that has passed the inspection should be packaged in containers with good sealing, corrosion resistance, non-toxic and odorless packaging materials. During the packaging process, long-term contact between the slurry and the air should be avoided to avoid volatilization of the organic carriers in the slurry causing performance changes. The packaged slurry should be marked with product name, batch number, production date and other information to facilitate traceability and management.

Summary and Outlook

This article introduces in detail the manufacturing method of base metal glass glaze resistor slurry for potentiometers, including the steps of raw material selection, batching, mixing, grinding, modulation, filtration, inspection and packaging. These steps are of great significance to ensure the quality and stability of the potentiometer.

In the future, with the advancement of science and technology and the development of the market, the performance requirements for base metal glass glaze resistor slurries used for potentiometers will become higher and higher, and the manufacturing methods will also be continuously optimized and improved.

By adopting new raw materials, optimizing process flow, improving automation and other measures, more efficient, environmentally friendly and more stable manufacturing of base metal glass glaze resistor slurries for potentiometers can be achieved.

Metallic Glass Glaze Resistors and Potentiometers FAQ

A potentiometer is an adjustable electronic component used to adjust the voltage or resistance value in a circuit. It usually consists of a resistor and a movable brush. The brush changes the resistance of the resistor by rotating or sliding, thereby adjusting the voltage or resistance value in the circuit. Potentiometers are widely used in various electronic devices, such as volume adjustment, brightness adjustment, power switches, etc. Depending on the application requirements, potentiometers can be divided into wirewound potentiometers, carbon film potentiometers, photosensitive potentiometers and other types.

A linear potentiometer is a special potentiometer whose resistance changes linearly with the movement of the slider. Linear potentiometers are often used in applications that require precise control of voltage or current, such as audio equipment, analog circuits, etc. Because its resistance value changes linearly, it can provide smooth adjustment effect and has a wide adjustment range. The accuracy and stability of linear potentiometers are key factors affecting their performance, so precise control and testing are required during the manufacturing process.

Glass resistor is a fixed resistor, usually composed of a metal conductor and a layer of glass. The glass is evenly coated on the surface of the resistor core through special process technology to form a protective layer, so that the resistor has good insulation properties. The working principle of glass resistors is based on Ohm’s law, which states that at a certain voltage, the current is proportional to the resistance. When electricity flows through a glass resistor, the electrons experience resistance, creating heat. This power conversion can be expressed as P=VI or P=I²R. Glass resistors mainly play a role in limiting current in circuits. They can be designed to limit voltage, control current, and measure electrical signals. At the same time, due to its high temperature resistance, corrosion resistance, moisture resistance and other characteristics, glass resistors are often used as circuit regulators, power filters and test components of various instruments and equipment.

The working principle of glass resistors is based on Ohm’s law, which states that at a certain voltage, the current is proportional to the resistance. When electricity flows through a glass resistor, the electrons experience resistance, creating heat. This power conversion can be expressed as P=VI or P=I²R. In a glass resistor, the glass acts as a medium to insulate and isolate, and the metal conductor acts as a resistor. When current passes through the metal conductor and the glass layer, the current is blocked due to resistance, causing the electrons in the metal conductor to slow down in the glass layer, thus producing resistance. The resistance value of a glass resistor will also vary due to the different resistivities of the metal conductors, as well as the thickness and uniformity of the glass layer. Therefore, by controlling parameters such as the material, shape and size of the metal conductor, as well as the thickness and uniformity of the glass layer, glass resistors with different resistance values can be produced.

Metallic glass glaze resistor is a coated resistor made of a mixture of metal oxide and glass glaze. The manufacturing process of this kind of resistor usually involves mixing metal oxides (such as ruthenium, silver, palladium, rhodium, tin, antimony, etc.) and glass glaze adhesives into a slurry, coating it on the insulating skeleton, and sintering it at high temperature. become. Metallic glass glaze resistors have excellent heat resistance, stability, reliability, corrosion resistance, moisture resistance and other properties, so they are widely used in electronic equipment. It can be used in electronic equipment such as signal generators, oscillators, and amplifiers to accurately control current and voltage to ensure the stability and reliability of electronic equipment. According to different combinations of metal oxides and glass glazes, the resistance and accuracy of metal glass glaze resistors can also be adjusted and controlled differently. In short, metallic glass glaze resistor is an important electronic component with wide application prospects.