The manufacturing process of electronic component manufacturers is the key to the quality of electronic products. The process involves multiple links from raw material preparation to finished product assembly, including cutting, forming, processing, welding, etc.

High-quality materials and advanced equipment are the basis of manufacturing, while technology is the core. In the future, intelligent manufacturing, green manufacturing and personalized customization will become trends.

Summary

This article studies the manufacturing process of electronic component manufacturers, including manufacturing processes, equipment, materials, technology, etc. By comparing and analyzing the manufacturing processes of different manufacturers, this article summarizes the characteristics and trends of electronic component manufacturing processes, and puts forward corresponding suggestions and improvement measures.

Keywords: electronic components, manufacturing technology, manufacturing process, equipment, materials, technology

introduction

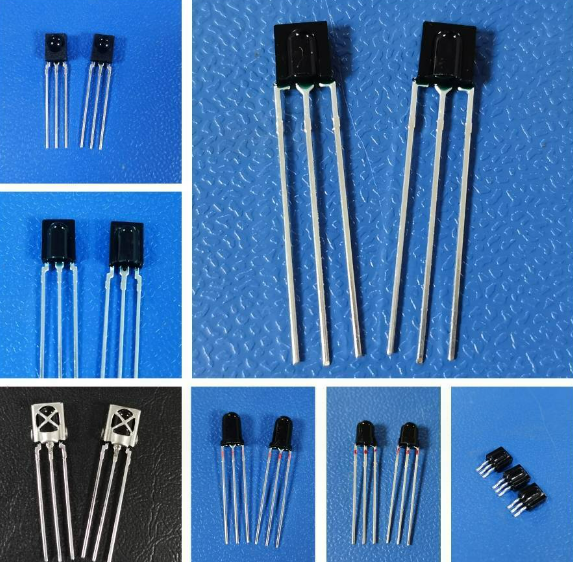

Electronic components are the core components of electronic products, and their manufacturing process is crucial to the performance and quality of the product. With the continuous development of science and technology, the manufacturing process of electronic components is also constantly improving and improving. This article aims to study the manufacturing processes of electronic component manufacturers and provide reference and reference for related companies and researchers.

Overview of electronic component manufacturing process

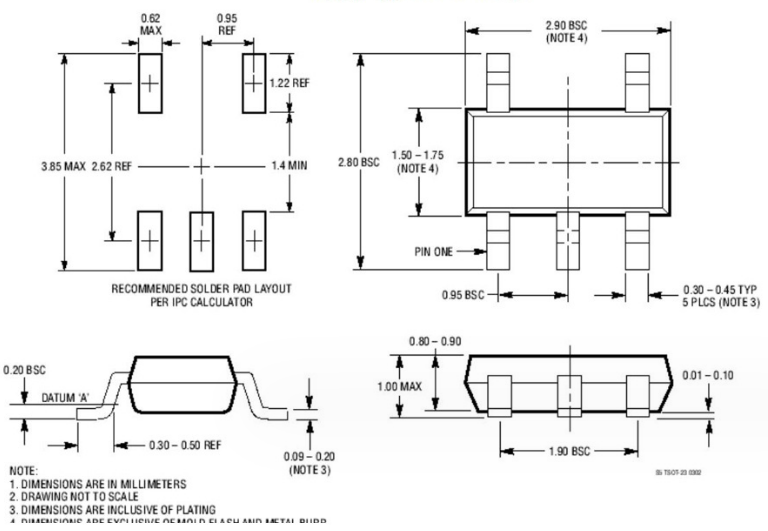

The manufacturing process of electronic components mainly includes manufacturing processes, equipment, materials and technologies. The manufacturing process refers to the entire process from raw materials to finished products, including raw material preparation, processing, assembly, testing and other links. Equipment is an important tool in the manufacturing process, including various machine tools, molds, fixtures, etc.

Materials are the basis of the manufacturing process, including conductive materials, insulating materials, magnetic materials, etc. Technology is the core of the manufacturing process, including manufacturing technology, detection technology, control technology, etc.

Comparison and analysis of electronic component manufacturing processes

Manufacturing process of electronic components

Different manufacturers have differences in their manufacturing processes, but generally they follow the process from raw material preparation to finished product assembly. Among them, the raw material preparation link includes procurement, inspection, storage, etc.; the processing link includes cutting, forming, processing, etc.; the assembly link includes welding, assembly, testing, etc.; the testing link includes functional testing, performance testing, etc.

Equipment required for electronic components

Different manufacturers also have differences in equipment, but generally they use advanced equipment and technology. Among them, cutting equipment includes laser cutting machines, mechanical cutting machines, etc.; molding equipment includes stamping machines, injection molding machines, etc.; processing equipment includes milling machines, lathes, etc.; welding equipment includes automatic welding machines, manual welding stations, etc.

Materials required for manufacturing electronic components

There are also differences in materials between different manufacturers, but generally they all use high-quality materials. Among them, the conductor materials use metal materials such as copper and aluminum; the insulating materials use polymer materials such as polyimide (PI) and polytetrafluoroethylene (PTFE); the magnetic materials use ferrite, neodymium iron boron, etc.

Electronic component manufacturing technology

There are also differences in technology between different manufacturers, but generally they all use advanced manufacturing technology. Among them, manufacturing technology includes precision processing technology, surface treatment technology, etc.; detection technology includes X-ray detection technology, ultrasonic detection technology, etc.; control technology includes computer-aided design (CAD), computer-aided manufacturing (CAM), computer-aided process planning (CAPP) )wait.

Electronic component manufacturing process characteristics and trends

Characteristics of electronic component manufacturing

(1) High precision: With the improvement of the performance of electronic products, the precision of electronic components is getting higher and higher, which requires the use of high-precision manufacturing equipment and processes.

(2) High efficiency: In order to meet market demand and improve competitiveness, the manufacturing of electronic components needs to achieve high-efficiency production.

(3) Environmental protection: With the improvement of environmental awareness, the manufacturing of electronic components needs to use environmentally friendly materials and processes to reduce the impact on the environment.

Trends in electronic component manufacturing

(1) Intelligent manufacturing: With the development of artificial intelligence technology, the manufacturing of electronic components will realize intelligent production, improving production efficiency and product quality.

(2) Green manufacturing: With the improvement of environmental awareness, the manufacturing of electronic components will use more environmentally friendly materials and processes to achieve green production.

(3) Personalized customization: With the diversification of consumer needs, the manufacturing of electronic components will realize personalized customized production to meet the needs of different customers.

Suggestions and improvement measures

Strengthen technological innovation

Enterprises should strengthen technological innovation and research and development, improve the technical level of manufacturing processes, reduce production costs and improve product quality.

Optimize manufacturing processes

Enterprises should optimize and improve manufacturing processes to improve production efficiency and quality levels. For example, advanced management methods and technical means such as concurrent engineering and lean production can be adopted.

Use advanced equipment

Enterprises should adopt advanced equipment and process technology to improve production efficiency and product quality levels. For example, advanced production equipment and technical means such as automated production lines and robots can be used.

Strengthen quality management

Enterprises should strengthen quality management and establish complete quality management systems and testing methods to ensure that product quality meets standards and customer requirements. For example, advanced management methods and technical means such as total quality management (TQM) and Six Sigma management can be adopted.

Difficulties and challenges in studying electronic component manufacturing processes

The difficulties and challenges in studying electronic component manufacturing processes mainly include the following aspects:

- Rapid technological updates: With the rapid development of science and technology, the manufacturing process of electronic components is also constantly updated. This means that researchers need to constantly learn and master new technologies to adapt to changing market needs.

- High equipment investment costs: The update of manufacturing processes often requires advanced equipment support. The procurement and maintenance costs of these equipment are usually high, which puts certain economic pressure on enterprises.

- Unstable supply of raw materials: The manufacturing of electronic components requires high-quality raw materials, and the supply of these raw materials is often affected by a variety of factors, such as market supply and demand, international trade policies, etc., resulting in unstable supply of raw materials.

- Increased environmental protection requirements: With the improvement of environmental awareness, the manufacturing process of electronic components needs to pay more attention to environmental protection and sustainable development. This requires companies to take more environmental protection measures during the production process to meet increasingly stringent environmental regulations.

- Diversified market demand: Different customers have different demands for electronic components, requiring companies to provide diversified products and services. This brings certain challenges to the company’s R&D and production, and the manufacturing process needs to be continuously adjusted and optimized to meet market demand.

In order to deal with these difficulties and challenges, companies can take the following measures:

- Strengthen technological R&D and innovation: By increasing investment in technological R&D and innovation, we will improve the technological level and core competitiveness of enterprises to adapt to changing market demands.

- Optimize equipment configuration and update: According to the actual situation of the enterprise and market trends, rationally configure and update equipment to improve equipment usage efficiency and economic benefits.

- Strengthen supply chain management: establish stable cooperative relationships with suppliers to ensure stable supply and quality assurance of raw materials.

- Promote environmental protection concepts: Actively promote environmental protection concepts during the production process, adopt environmental protection measures, and reduce environmental pollution during the production process.

- Improve customized service capabilities: Strengthen communication and cooperation with customers, improve customized service capabilities, and meet the diverse needs of customers.