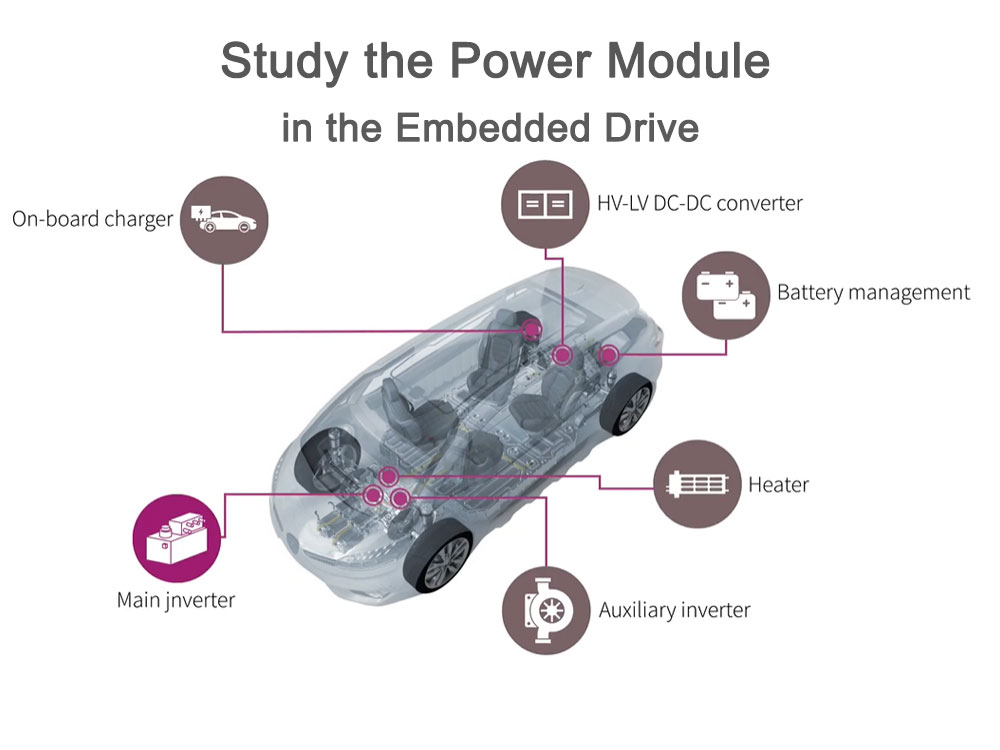

Research on power modules in embedded drives focuses on improving their energy efficiency, stability and lifespan to adapt to changing application requirements and promote energy conservation, emission reduction and system performance optimization.

Embedded discussion

With the rapid development of technology, the application of embedded systems in various fields is becoming more and more widely used, such as smart homes, industrial control, medical equipment, etc.

As an important part of the embedded system, the power module provides a stable energy source for the entire system, and its performance directly affects the stability and reliability of the entire system.

Therefore, in -depth research on the power module in embedded drivers has important theoretical and practical significance.

Overview of the power module in the embedded drive

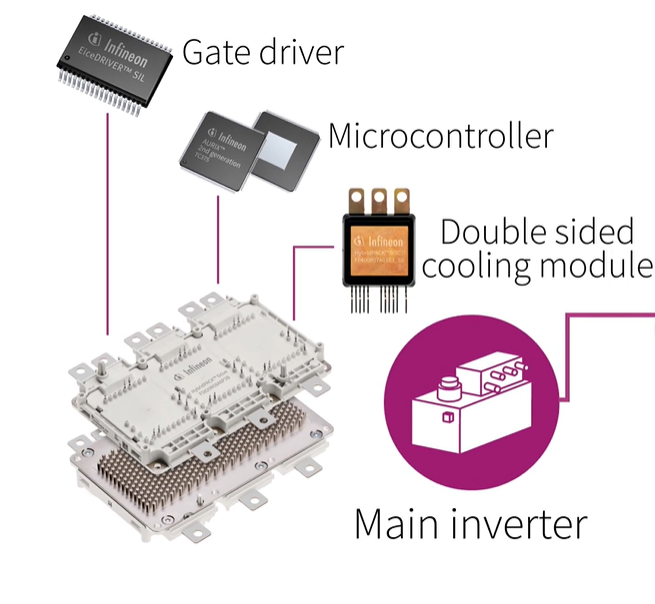

The power module is the core part of the embedded drive, which is mainly responsible for converting the input power energy to the voltage and current suitable for embedded systems. It usually includes a rectifier circuit, filter circuit, voltage voltage circuit and other parts, which can realize functions such as voltage conversion, stability and protection.

The performance indicators of the power module mainly include efficiency, power density, and reliability. Among them, the efficiency determines the energy conversion efficiency of the power module, and is an important indicator of the performance of the power module. The power density reflects the performance of the volume and weight of the power module; reliability is an important thing for the power module to run stable for a long time. Assure.

Power module design in embedded drive

The design of the power module requires comprehensive consideration of system requirements, electrical characteristics, and heat design. During the design process, the input and output voltage, current and other parameters of the power module need to be determined according to the maximum power consumption and voltage requirements of the system. At the same time, it is also necessary to consider the requirements of the efficiency, power density, and reliability of the power module to ensure that the power module can meet the long -term stable operation of the system.

In addition, in order to improve the reliability of the power module, a series of optimization measures are needed, such as choosing high-quality electronic components, optimizing circuit design, and strengthening heat dissipation design.

How does the power module in the embedded driver be designed with the power module

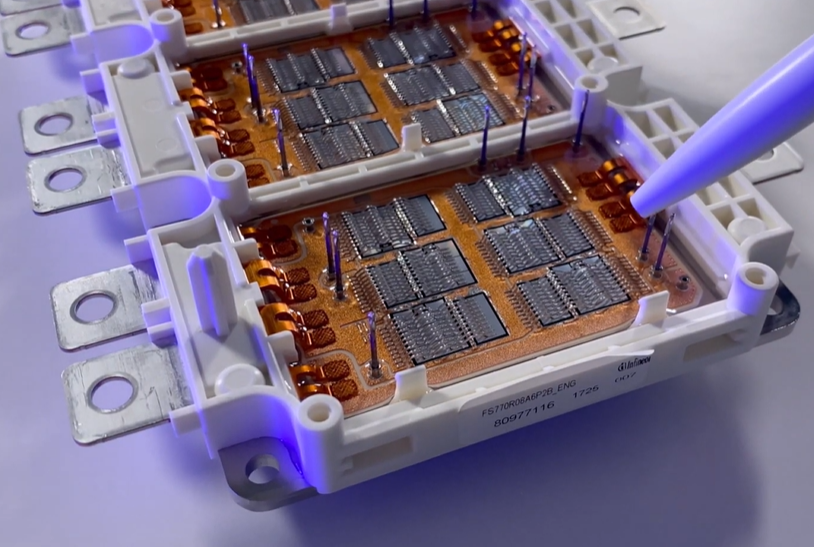

In the cooling design of the power module in the embedded drive, the main consider how to effectively export the heat from the power module and reduce its working temperature to ensure the stable operation of the power module and extend its service life. Here are some points of some cooling design:

- Understand the heat source: First of all, you need to understand the main thermal sources in the power module, such as power semiconductors, inductors and capacitors. These components generate a lot of calories when converting electrical energy.

- Natural cooling or forced cooling: According to the heat dissipation needs of the power module, you can choose natural cooling or forced cooling method. Natural cooling mainly relies on the natural flow of air to dissipate heat, which is suitable for lower thermal density. For compulsory cooling, it is necessary to use a fan or other forced ventilation equipment to be suitable for high -heat flow density.

- The radiator design: If you need to use a radiator, you should choose the appropriate material (such as copper or aluminum) and shape to effectively export the heat from the power module. At the same time, the surface area of the radiator should be large enough to quickly emit calories.

- Heating material: The heat conduction material (such as thermal grease or thermal pad) should be used between the power module and the radiator to transmit the heat from the power module to the radiator.

- Isolation and protection: In order to prevent dust and other impurities from affecting the heat dissipation effect, appropriate protection and isolation measures should be set around the power module.

- Monitoring and control: You can install the temperature sensor to monitor the working temperature of the power module, and use the control circuit to adjust the working state of the power module to maintain it within the appropriate temperature range.

- Consider cost and space limit: In the design of heat dissipation, cost and space restrictions should be considered. Select the appropriate heat dissipation solution to meet the heat dissipation needs of the power module, and also consider the cost and size requirements of the product.

In short, in the cooling design of the power module in the embedded drive, multiple factors need to be comprehensively considered, such as heat sources, heat dissipation methods, heat sink design, heat conduction materials, protection measures, cost and space restrictions. Through a reasonable heat dissipation design, the working temperature of the power module can be effectively reduced to ensure its stable operation and extend its service life.

What is the difference between linear power module and switching power module

There are significant differences in linear power modules and switching power modules in multiple aspects:

- Working principle: The working principle of the linear power module is to reduce the voltage and stable output through the coil transformer. The working principle of the switching power module uses the switch device (such as MOSFET) to convey and adjust the voltage by high frequency switching.

- Efficiency: The efficiency of the switching power module is usually high, which can reach more than 80%of the energy conversion efficiency, and the efficiency of linear power modules is relatively low, generally between 50%and 60%.

- Volume and weight: Because the switching power module uses a high -frequency switch to switch to achieve voltage conversion, its components can complete the voltage conversion in a smaller space, so the volume is small and the weight is relatively light. The linear power module needs to use large coil transformers and radiator components, and the volume and weight are relatively large.

- Cost: Generally, the manufacturing cost of switching power modules is relatively low because they use less materials and components. The manufacturing cost of linear power modules is relatively high because more coil transformers and larger radiators need to be used.

- Stability: Linear power modules usually have lower noise and good stability, and can provide clean output power. The switching power module may produce some electromagnetic interference and noise due to high -frequency switching.

In summary, linear power modules and switching power modules have their own advantages and disadvantages in terms of efficiency, volume, weight, cost, and stability. In practical applications, you can choose the appropriate power module type according to the needs.

Are there any environmentally friendly power modules, can I introduce it?

Environmental protection power module refers to the power module that meets environmental protection requirements. It uses environmental protection materials and production processes, which has a small impact on the environment.

Here are some common environmental protection power modules:

- Green power module: The green power module is an efficient power -saving power module. It uses advanced control technology and high -efficiency switching power supply. It has the characteristics of energy saving, low noise, and low pollution. It is in line with the development trend of computer technology and can be recycled and reuse after the service life is over.

- Switching power module: The switching power module is a small, high-efficiency, and high reliability power module. It uses switch tube or power MOSFET and other devices to achieve voltage conversion and adjustment through high -frequency switch switching. It has the advantages of small size, light weight, high efficiency, high reliability, and meets the requirements of energy saving and emission reduction.

- Converter: The converter can convert a fixed DC voltage to a variable DC voltage, which is applied to the field -free transmission and control of trackless trams, subway trains, electric vehicles. This power module uses advanced control technology to reduce energy consumption and improve energy utilization efficiency, and at the same time can reduce noise and pollution to the environment.

- UPS: UPS (uninterrupted power supply) is a power module that can provide continuous stable power supply, which is mainly used in the fields of computer, communication systems and data storage devices. It can ensure the normal operation of the device and the integrity of data in the case of power outage or voltage fluctuations. The UPS power module adopts high -efficiency switching power supply technology and advanced uninterrupted power supply technology, which can reduce energy waste and environmental pollution.

These environmentally friendly power modules use environmentally friendly materials and advanced production processes, which have the characteristics of efficient, energy saving, low noise, low pollution, etc., and meet the current society’s requirements for environmental protection and sustainable development.

The latest development of the power module in the embedded drive

With the continuous advancement of technology, the power module in embedded drivers is also developing. At present, the switching power supply technology has become the mainstream, and it has the advantages of high efficiency, small volume, and light weight. At the same time, some new power management technologies have also emerged, such as distributed power management systems based on power electronic technology, high -density integration power modules based on magnetic components. The development of these new technologies provides more choices and possibilities for power modules in embedded drives.

In addition, in order to meet the needs of green and environmental protection, lead and halogen -free environmental protection power modules have also been widely used. These power modules have higher reliability and longer service life, which meets the current society’s requirements for environmental protection and sustainable development.

The power module in the embedded driver concludes

The power module in the embedded drive is an important guarantee for the stable operation of the entire system. With the continuous development of technology, the performance of the power module is also continuously improved, and the application of new power management technology and environmental protection power modules is becoming wider and wider.

In order to better meet the needs of the system, future power module design needs to pay more attention to the performance of efficiency, power density and reliability.

At the same time, with the development of emerging technologies such as artificial intelligence and the Internet of Things, the power module in the embedded drive also faces new challenges and opportunities. Therefore, we need to continuously study and explore to promote the continuous development and progress of power module technology in embedded drivers.

Frequently Ask Q & A in the power module in embedded drivers

The power module in the embedded driver is an energy converter in the entire system. It is responsible for converting the input electrical energy into voltage and current suitable for embedded systems to provide stable power supply for each part of the system.

There are two types of power modules: linear power modules and switching power modules. The linear power module adopts linear voltage voltage technology, which has a lower voltage noise and better stability. The switching power module uses switching voltage technology, which has high efficiency and miniaturization characteristics.

The performance of the evaluation of the power module mainly includes indicators such as efficiency, power density, and reliability. Among them, efficiency determines the energy conversion efficiency of the power module, and the power density reflects the performance of the volume and weight of the power module, and reliability is an important guarantee for the power module to run stable for a long time.

Selecting the right power module needs to be determined according to the needs of the system and electrical characteristics. The factors that need to be considered include input output voltage, current, power density, efficiency, reliability, etc. In addition, the size, weight, and cost of the power module must be considered.

Optimizing the design of the power module requires comprehensive consideration of multiple aspects. Including choosing high -quality electronic components, optimizing circuit design, strengthening heat dissipation design, etc. In addition, new power management technology and environmentally friendly power modules can be used to improve the performance and reliability of the power module.