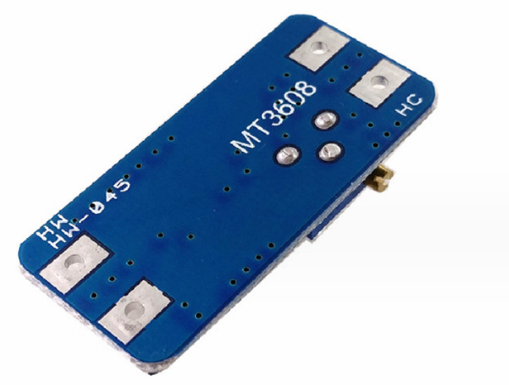

What is MT3608 boost module converter?

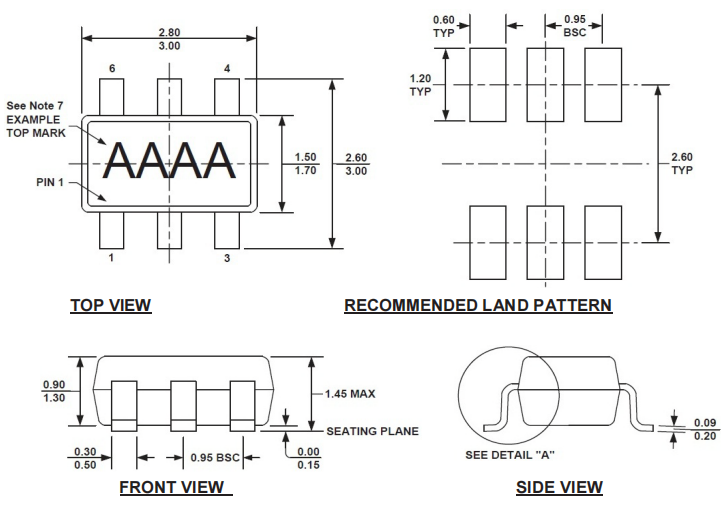

The MT3608 is a high-efficiency, 1.2MHz, 2A boost converter with the characteristics of a constant frequency, 6-pin SOT23 current mode boost converter. It is suitable for small, low-power applications. The MT3608’s switching frequency is 1.2MHz, allowing the use of tiny, low-cost capacitors and inductors with a height of 2mm or less. An internal soft-start feature reduces inrush current, extending battery life. In addition, MT3608 also has the function of automatically switching to pulse frequency modulation mode under light load. It also includes undervoltage lockout, current limiting, and thermal overload protection to prevent damage if the output is overloaded. MT3608 is available in 6-pin SOT-23 package.

What are the features of the MT3608 DC-DC boost power converter module?

Key features of the MT3608 DC-DC boost power converter module include:

Wide input voltage range

MT3608 can accept a wide input voltage range, making it suitable for different power supply situations, including battery power supply or regulated power supply.

high efficiency

MT3608 adopts an efficient switching regulator working principle, which can reduce energy loss and improve energy efficiency.

small package

MT3608 is packaged in a 6-pin SOT-23, which takes up little space and is easy to integrate into small devices.

Current limit and thermal protection features

MT3608 has built-in current limit and thermal protection functions to prevent overload and circuit damage and improve system reliability.

Automatically switch to pulse frequency modulation mode

Under light load, MT3608 can automatically switch to pulse frequency modulation mode to reduce power consumption and extend battery life.

The MT3608 boost converter is suitable for applications such as battery-powered equipment, set-top boxes, LCD backlight power supply, DSL and cable modems and routers. When selecting MT3608, factors such as input voltage range, output current requirements, efficiency requirements, and package size need to be considered.

Can you give more functions of MT3608?

MT3608 has the following functions:

Internal soft start function

This feature reduces inrush current during startup, thereby extending battery life.

Automatically switch to pulse frequency modulation mode

At light load, MT3608 automatically switches to pulse frequency modulation mode, which helps reduce power consumption.

Undervoltage lockout, current limit and thermal overload protection

These protection functions can prevent damage when the output is overloaded and improve the stability and reliability of the system.

Allows the use of tiny, low-cost capacitors and inductors

Since the MT3608 switches at a frequency of 1.2MHz, it is possible to use tiny, low-cost capacitors and inductors with a height of no more than 2mm, which helps reduce the size and cost of the entire circuit.

Overall, the MT3608 is an efficient and reliable boost converter with multiple protection features and a small package, making it suitable for a variety of small, low-power applications. At the same time, it also has functions such as internal soft start and automatic switching of pulse frequency modulation mode, which can reduce power consumption and extend battery life.

In addition, MT3608 also has the characteristics of wide input voltage range and high efficiency. These features make the MT3608 an efficient and reliable solution in a variety of applications.

How is the internal soft-start function of MT3608 implemented?

The internal soft-start function of MT3608 is achieved by controlling the current slope when the power supply is started. When the power supply is turned on, internal circuitry gradually increases the output voltage, thereby limiting sudden inrushes of current. This can reduce the impact when the power supply is started and avoid excessive current stress on the components in the circuit, thus extending the service life of the power supply and related components.

The working principle of the internal soft-start function is that when the power is turned on, the control circuit inside the MT3608 will monitor the output voltage and gradually adjust its slope to control the increase rate of the current. By gradually increasing the output voltage, you can reduce the inrush current at startup and reduce the current stress on the power supply and related components.

This soft-start function can effectively protect the circuit from the impact of power startup and improve the stability and reliability of the entire system. It is particularly suitable for applications that require frequent starts or require a smooth start of the power supply, such as portable devices, electronic equipment, and battery-powered systems.

In short, the internal soft-start function of MT3608 is achieved by controlling the slope of the output voltage, which can effectively reduce the inrush current during startup and protect the circuit from the impact of power supply startup. This function can improve the stability and reliability of the system and is especially suitable for applications with high power startup requirements.

How is the efficiency of MT3608 calculated?

The efficiency of MT3608 can be calculated by the following formula:

Efficiency = (Output Voltage / Input Voltage) x 100%

Among them, the output voltage refers to the output terminal voltage of MT3608, and the input voltage refers to the input terminal voltage of MT3608.

Efficiency is an important indicator of the performance of a power converter. It indicates how efficiently the power converter converts input voltage into output voltage. High efficiency means less energy is lost during the conversion process, which can reduce energy waste and improve power usage efficiency.

MT3608 is a boost converter, which usually has high conversion efficiency. In practical applications, the efficiency of MT3608 will be affected by many factors, such as input voltage, output voltage and load. Therefore, in order to obtain the best efficiency, it is necessary to select the appropriate input voltage, output voltage and load conditions according to the actual application scenario.

In addition, in order to improve the efficiency of MT3608, some design measures can also be taken, such as optimizing the circuit topology, selecting low-loss components, reducing heat loss, etc. These measures can help reduce the energy loss of the power converter and improve the efficiency of power supply.

Is there any other formula to calculate the efficiency of a power converter?

In addition to the formulas mentioned above, the following formula can be used to calculate the efficiency of a power converter:

Efficiency = (output power / input power) x 100%

Among them, the output power refers to the product of the output voltage and current of the power converter, and the input power refers to the product of the input voltage and current of the power converter.

This formula is slightly different than the above formula, but they are actually equivalent. When calculating the efficiency of a power converter, parameters such as input voltage, output voltage, and current need to be considered, and an appropriate formula should be selected for calculation based on the actual situation.

In addition, the efficiency of power converters can also be measured experimentally. Usually, an experimental circuit is built to measure the input voltage, output voltage, current and other parameters of the power converter, and calculate the efficiency value. The experimental method can more accurately reflect the actual performance of the power converter, but requires certain experimental conditions and equipment.

In short, calculating the efficiency of a power converter requires using appropriate formulas and selecting input voltage, output voltage, current and other parameters for calculation according to the actual situation. The experimental method can more accurately reflect the actual performance of the power converter, but requires certain experimental conditions and equipment.

What factors affect the efficiency of MT3608?

The efficiency of the MT3608 is affected by many factors, including input voltage, output voltage, load conditions, circuit topology, component selection, and heat loss.

Among them, input voltage and output voltage are one of the important factors affecting the efficiency of MT3608. When the input voltage and output voltage differ greatly, the conversion efficiency decreases because more energy is required to maintain the conversion process. At the same time, the higher the output voltage, the higher the conversion efficiency will be.

Load conditions are also one of the factors affecting the efficiency of MT3608. The efficiency of the converter may be reduced when the load is light because the losses in the converter may increase at light loads. Conversely, when the load is heavier, the converter efficiency may be higher because the load current can share some of the conversion losses.

Circuit topology is another important factor affecting the efficiency of MT3608. Different circuit topologies will have different energy losses and efficiency performances. Optimizing the circuit topology can improve conversion efficiency and reduce energy loss.

In addition, component selection and heat loss can also affect the efficiency of the MT3608. Choosing low-loss components can reduce energy loss in the circuit and improve efficiency. At the same time, heat loss is also one of the factors that needs to be considered. Excessively high temperatures will lead to component performance degradation and increased energy loss, thereby reducing conversion efficiency.

To sum up, the efficiency of MT3608 is affected by many factors, including input voltage, output voltage, load conditions, circuit topology, component selection and heat loss, etc. In order to obtain the best efficiency, it is necessary to select the appropriate input voltage, output voltage and load conditions according to the actual application scenario, and take corresponding design and optimization measures.

What other factors affect the efficiency of a power converter?

The efficiency of MT3608 is mainly affected by the following factors:

Input voltage

The size of the input voltage directly affects the efficiency of MT3608. If the input voltage is too high or too low, the conversion efficiency will decrease. Therefore, choosing the appropriate input voltage range is very important to improve the efficiency of MT3608.

The output voltage

The level of the output voltage will also affect the efficiency of MT3608. Generally speaking, the higher the output voltage, the higher the conversion efficiency will be. However, if the output voltage is too high, it may cause the circuit to overheat, reducing efficiency.

load conditions

Load conditions are also one of the factors affecting the efficiency of MT3608. The efficiency of the converter may be reduced when the load is light because the losses in the converter may increase at light loads. Conversely, when the load is heavier, the converter efficiency may be higher because the load current can share some of the conversion losses.

Circuit topology

Circuit topology is another important factor affecting the efficiency of MT3608. Different circuit topologies will have different energy losses and efficiency performances. Optimizing the circuit topology can improve conversion efficiency and reduce energy loss.

Component Selection and Heat Loss

Choosing low-loss components can reduce energy loss in the circuit and improve efficiency. At the same time, heat loss is also one of the factors that needs to be considered. Excessively high temperatures will lead to component performance degradation and increased energy loss, thereby reducing conversion efficiency.

In summary, to improve the efficiency of MT3608, factors such as input voltage, output voltage, load conditions, circuit topology, component selection, and heat loss need to be comprehensively considered, and corresponding design and optimization measures must be taken.

How to use mt3608?

When using the MT3608 boost module, you can follow the steps below:

Confirm input voltage range

Check the MT3608 specification sheet or data sheet to confirm whether the input voltage range matches your power supply voltage.

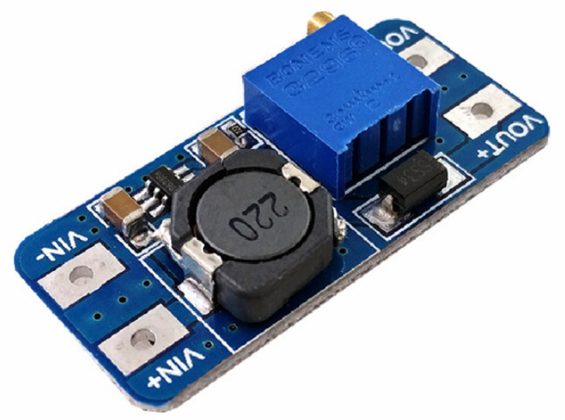

Circuit connection

Connect the input of the MT3608 module to your power supply and the output to your load. Make sure the power supply voltage is higher than the minimum startup voltage of MT3608.

Adjust output voltage

According to your needs, the voltage of the load can be controlled by adjusting the output voltage of the module. Usually, you can adjust the output voltage by adjusting the potentiometer on the module or using an adjustable resistor.

Connect protection circuit

In order to protect the MT3608 module and your load, you can add some protection circuits, such as overvoltage protection, overcurrent protection, and overtemperature protection.

Testing and Debugging

After connecting the circuit, perform testing and debugging. Check whether the output voltage meets your requirements and make sure the module can work stably under various conditions.

It should be noted that the MT3608 boost module is a professional electronic component and requires certain basic knowledge of electronics when using it. If you are not familiar with electronic circuits and component selection, it is recommended to operate under the guidance of professionals.

mt3608 module not working

The MT3608 module may not work for the following reasons:

Input voltage is too low

The MT3608 boost module has a minimum starting voltage requirement. If the input voltage is lower than this requirement, the module will not start and work properly. Please ensure that the input voltage is higher than the minimum startup voltage specified in the MT3608 specifications.

Wrong circuit connections or component selection

Please check whether your circuit connections are correct, including input and output power wiring, capacitor and inductor selection, circuit layout, etc. Make sure the components you use meet the specifications of the MT3608.

Overloaded

If the load current exceeds the rated current capability of MT3608, the module may not be able to boost normally. Please ensure that the load current is within the specifications of MT3608.

Where can I find the mt3608 datasheet?

You can click here to download the mt3608 datasheet PDF, which can be downloaded directly from our website.

Of course, you can also find the MT3608 data sheet on the electronic component supplier’s website or data sheet library.

Some well-known electronic component suppliers include TI (Texas Instruments), Maxim (Maxim), NXP (NXP), etc. You can search for MT3608 related information on the websites of these companies. In addition, you can also search for MT3608 data sheets on the websites of electronic component distributors, such as Mouser, Digikey, Farnell, etc. When looking for a datasheet, be sure to select the one that matches the MT3608 package and batch number you are using.