Are boost modules and buck modules electronic components?

Boost modules and buck modules are electronic components. These modules are usually composed of electronic components (such as inductors, capacitors, diodes, transistors, etc.) and are used to convert and regulate voltage.

A boost module is a circuit module that can increase the input voltage. It is usually used to convert low voltage to high voltage to meet the needs of a specific device or system. The buck module is a circuit module that can reduce the input voltage. It is usually used to convert high voltage to low voltage to adapt to different load conditions.

These modules are widely used in various fields such as electronic equipment, industrial automation, automotive electronics, new energy fields, aerospace, etc., and play an important role in improving equipment performance, reducing energy consumption, and improving system stability.

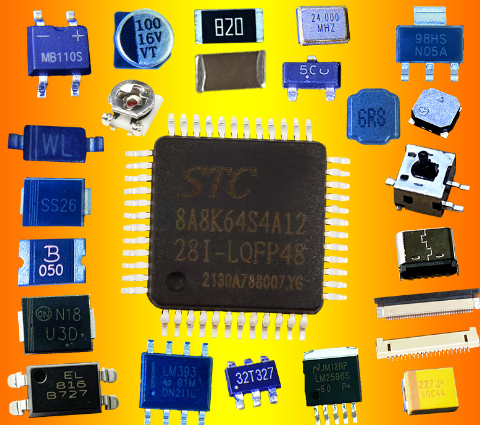

What electronic components do boost modules and buck modules consist of?

Boost modules and buck modules are usually composed of a variety of electronic components, including but not limited to:

Inductor

Inductors are used to store energy and pass current in a circuit. In the boost module, the inductor is usually used in conjunction with the switching tube to increase the voltage. In buck modules, the inductor is used to smooth the output voltage and reduce ripple.

capacitor

Capacitors are used to store electrical charge and pass voltage in a circuit. In boost and buck modules, capacitors are often used to filter and smooth the output voltage.

diode

Diodes are used to control the flow of electrical current. In boost modules, diodes are often used to prevent current from flowing back into the supply. In buck modules, diodes are used to reduce the voltage.

transistor

Transistors are used to amplify and control electrical current. In boost modules and buck modules, transistors are usually used as switching tubes to control the on and off of current to achieve voltage conversion.

It should be noted that the above are only common electronic components in boost modules and buck modules. The specific component composition may vary depending on circuit topology, output voltage, input voltage and other factors.

In addition, in order to improve efficiency and stability, the boost module and the buck module may also contain other auxiliary components, such as protection circuits, feedback circuits, etc. These auxiliary components help realize circuit protection, regulation and monitoring functions.

Which one has greater loss, the boost module or the buck module?

Under the same load conditions, the loss of the boost module is usually greater than that of the buck module. This is because the boost module requires higher input current to produce the required output voltage, resulting in higher internal resistance losses and coil losses. In addition, the boost module also requires a higher switching frequency, which also increases switching losses.

However, it is important to note that the amount of loss is also affected by factors such as circuit topology, component selection, and thermal management. Therefore, in practical applications, the loss size should be evaluated and optimized on a case-by-case basis.

When selecting a boost or buck module, a variety of factors need to be considered, including the required output voltage, input voltage range, load conditions, efficiency requirements, and circuit and component complexity. In some cases, using a buck scheme may be more appropriate, as buck conversion typically has higher efficiency and can provide better performance under certain load conditions.

What are the advantages of boost modules and buck modules with low losses?

Low-loss boost modules and buck modules have the following advantages:

high efficiency

Boost modules and buck modules with small losses usually have high conversion efficiency and can effectively convert the input voltage into the required output voltage, thereby reducing energy waste.

Energy saving and environmental protection

High-efficiency boost modules and buck modules generate less heat during operation, reducing heat dissipation problems and thereby reducing thermal pollution to the environment. In addition, reducing energy waste also helps reduce carbon emissions and meets the requirements of energy conservation and environmental protection.

Extended service life

Boost modules and buck modules with low losses generate less heat when working, thus reducing the aging and damage of components, thereby extending the service life of the module.

cut costs

High-efficiency boost and buck modules reduce energy waste, thereby lowering operating costs. In addition, extended service life also reduces the frequency of module replacement and maintenance costs.

Improve system stability

Boost modules and buck modules with small losses usually have better temperature stability and load stability, and can maintain stable output voltage and current under various operating conditions, thus improving the stability of the entire system.

It should be noted that to achieve low-loss boost modules and buck modules, a series of design and optimization measures need to be taken, such as selecting appropriate circuit topology, selecting low-loss components, optimizing thermal management, etc. In addition, in practical applications, it is necessary to select an appropriate boost or step-down solution based on specific load conditions and efficiency requirements.

In what fields are boost modules and buck modules with low losses widely used?

Low-loss boost modules and buck modules are widely used in many fields, including but not limited to:

Electronic equipment

In electronic equipment such as smartphones, tablets, and laptops, a boost module is needed to convert the low voltage of the battery into the high voltage required by the equipment. Likewise, step-down modules are also used to convert high voltage into low voltage for use in different parts of the equipment.

Industrial automation

In industrial automation systems, various sensors, actuators and controllers require different voltage levels. Low-loss boost and buck modules can help achieve these voltage conversions, thereby improving system efficiency and stability.

Automotive electronics

In automotive electronic systems, a boost module is needed to convert the 12V voltage of the battery into high voltage to supply components such as motors and generators. At the same time, the voltage step-down module is also used to convert high voltage into low voltage for use in vehicle electronic equipment.

New energy fields

In new energy fields such as solar energy and wind energy, boost modules are needed to convert the low voltage output by solar panels or wind turbines into the high voltage required for grid connection. Likewise, step-down modules are used to convert high voltage to low voltage suitable for use in home appliances or industrial equipment.

Aerospace

In the aerospace field, high-efficiency, high-reliability boost modules and buck modules are needed to meet the strict requirements of aircraft, satellites and other equipment. These modules need to have features such as wide input voltage range and high temperature operating capability.

In short, boost modules and buck modules with small losses are widely used in various fields and play an important role in improving equipment performance, reducing energy consumption, and improving system stability.