Research on the reliability of DC/DC power module

Reliability research on DC/DC power modules is a multi-faceted topic that requires analysis from multiple perspectives such as module principles, applications, environmental factors, and failure modes.

The following is a brief research report summary designed to provide an in-depth understanding of this topic.

Introduction to DC/DC module reliability research

As a key component of power conversion, DC/DC power modules are widely used in various electronic equipment.

Due to their compact size, high efficiency and high reliability, DC/DC power modules have become the first choice for many applications. However, as the complexity of electronic equipment increases, the reliability problem of power modules becomes more and more prominent. Therefore, it is of great practical significance to study the reliability of DC/DC power modules.

Working principle of DC/DC power module

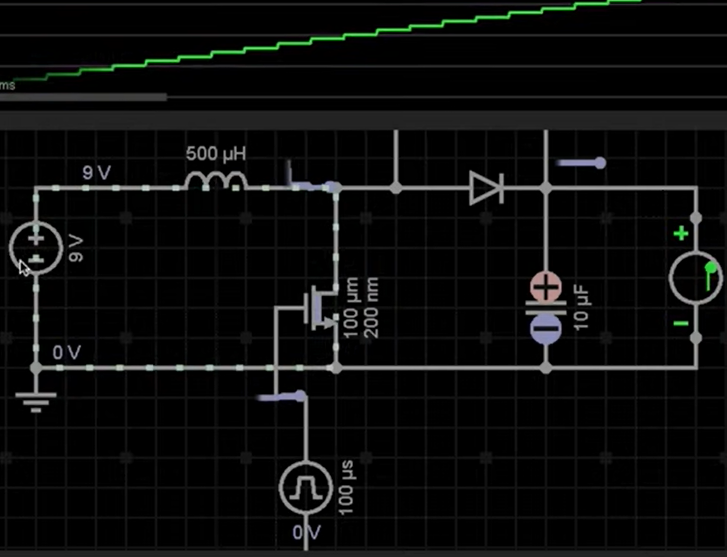

DC/DC power module is a power supply that converts DC input voltage into DC output voltage. Its working principle mainly includes two processes: voltage conversion and current control. Voltage conversion is achieved through switching tubes and magnetic components (such as transformers and inductors), while current control is achieved through error amplifiers and feedback loops.

Factors affecting the reliability of DC/DC power modules

- Component aging: Components in the power module, such as switching tubes, magnetic components and capacitors, will gradually age with time, affecting the reliability of the module.

- Environmental factors: Environmental factors such as ambient temperature, humidity, vibration, and electromagnetic interference will also affect the reliability of the power module.

- Load characteristics: The load characteristics of the power module, such as the size and change of the load current, also have an important impact on the reliability of the power module.

- Design and manufacturing process: The design and manufacturing process of the power module also have a great impact on its reliability. Reasonable circuit design, high-quality components and strict manufacturing processes can improve the reliability of power modules.

- Use and maintenance: Improper use and maintenance will also affect the reliability of the power module. For example, excessive use, lack of regular cleaning and maintenance, etc.

Methods to improve the reliability of DC/DC power modules

- Choose high-quality components: Choosing high-quality components can effectively improve the reliability of the power module.

- Optimize circuit design: Optimizing circuit design can improve the stability and efficiency of the power module, thereby reducing the failure rate.

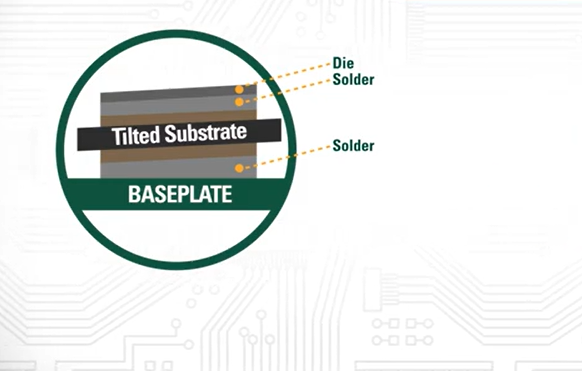

- Enhanced heat dissipation design: Enhanced heat dissipation design can prevent the power module from overheating, thereby reducing the aging rate of components.

- Improve the level of manufacturing technology: Improving the level of manufacturing technology can reduce damage to components during the manufacturing process, thereby improving the reliability of the power module.

- Implement regular maintenance: Regular inspection and maintenance of the power module can detect and solve potential problems in time, thus improving its reliability.

- Choose a suitable application environment: Understanding and choosing a suitable application environment can prevent power module failures caused by environmental factors.

- Properly select and use loads: Understanding and rationally selecting and using loads can prevent power module failures caused by load problems.

- Enhance the maintainability of the power module: Considering the maintainability of the power module during the design stage can reduce troubleshooting and repair time during later use, thereby improving its reliability.

How to design DC/DC power module to improve its reliability

To improve the reliability of DC/DC power modules, you can start to consider it from the design stage. Here are some design tips:

- Redundant design: In situations with high reliability requirements, even if the power module is damaged, the system cannot be powered off. At this time, redundant power supply can be used to improve system reliability. When one power module is damaged, the other module can continue to provide power.

- Temperature Management: Properly arrange radiators, fans and other cooling devices to ensure that the module works within a suitable temperature range, which can reduce the failure rate.

- Electromagnetic compatibility design: Ensure that the module has good anti-interference ability and avoid electromagnetic radiation and electromagnetic susceptibility interference. For example, the input and output ends of the module need to be filtered and isolated.

- Voltage margin design: Set a reasonable margin for the operating voltage, and consider voltage fluctuations and ripple factors in module design to prevent power supply collapse.

- Protection measures: Use overvoltage, overcurrent and overheating protection circuits to prevent the module from being damaged under extreme working conditions.

- Unbalanced dual-channel power and voltage output design: For modules with unequal output power, there are two main design methods: one is to use transformer windings and use coupled inductors and low-voltage stabilizing circuits Perform secondary voltage stabilization method. The second is to use multiple secondary windings of the transformer to output two relatively independent voltages. Although method one can improve the stability of the circuit and ensure the accuracy of the output voltage, it will increase the loss of the circuit. If method 2 is adopted, since the feedback can only control one voltage, the accuracy of only one output voltage can be guaranteed. The voltage of the other voltage can only be pre-stabilized by the transformer and filter inductor, and the main output power will inevitably change greatly. It brings about large changes in the secondary voltage of the auxiliary circuit transformer, so the accuracy of the output voltage cannot be guaranteed. To this end, this design uses two outputs for independent control and feedback, so that the output voltage can be accurately controlled and the losses caused by secondary voltage stabilization can be reduced.

- Derating design: When the power supply is fully loaded for a long time, its service life will be shortened. The derating design can effectively increase the service life of the power supply. The high-energy cubic ACDC module power supply is recommended to be used within the load range of 30%~80% for the best performance in all aspects.

- Peripheral protection design: Reasonable design can protect the power module from the external environment. For example, appropriate filter circuits or capacitors can be added to reduce ripple noise or improve power supply stability.

These design techniques can improve the reliability of DC/DC power modules to a certain extent, but it should be noted that each application scenario has its own unique environment and requirements, so selections need to be made based on the actual situation during the specific design process. and applications.

DC/DC power module reliability conclusion

The reliability of DC/DC power modules is crucial to their wide application. From component selection, circuit design, manufacturing process to use and maintenance, all aspects need to be fully considered and effective strategies implemented to improve its reliability.

With the continuous development of science and technology, we also need to continue to conduct in-depth research on new technologies and methods to further improve the reliability of DC/DC power modules and meet the growing demand for electronic equipment.