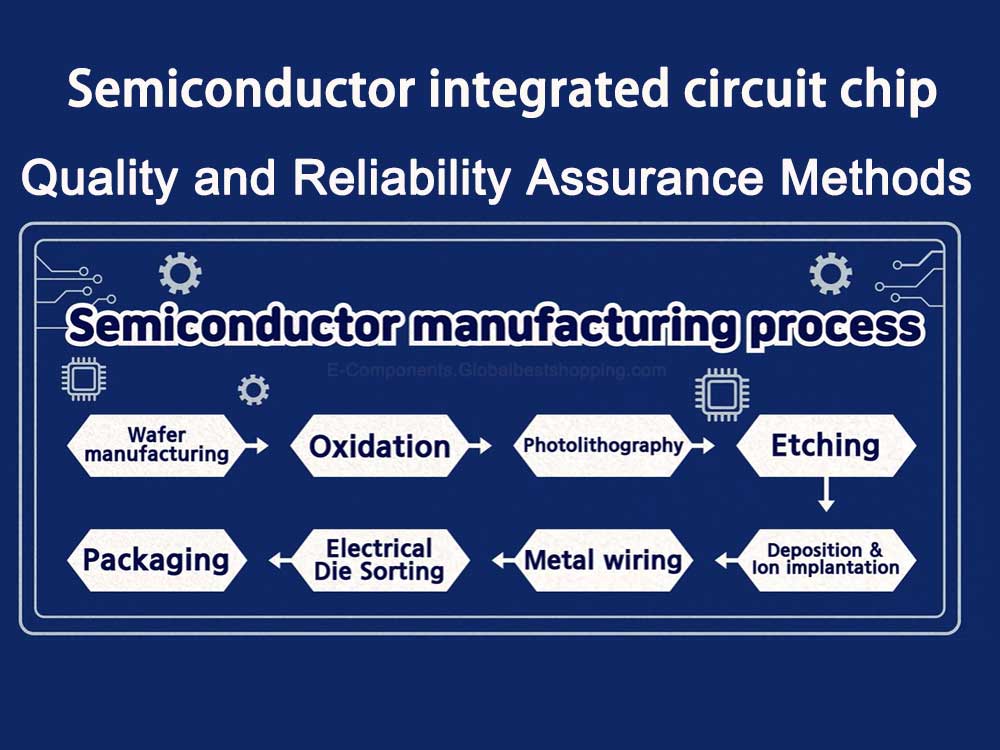

Semiconductor integrated circuit chip quality and reliability assurance methods

Semiconductor integrated circuit chip quality and reliability assurance methods include strict selection of raw materials, refined manufacturing processes, multi-level testing and verification, and continuous quality monitoring.

Through these methods, the chip performance is ensured to be stable and reliable, and to meet various application needs.

Overview

With the rapid development of science and technology, semiconductor integrated circuits (ICs) have become the core part of modern electronic products.

Whether it is mobile phones, computers, automobiles, or industrial equipment, they are all inseparable from semiconductor integrated circuits.

However, due to the complexity of semiconductor integrated circuits, how to ensure their quality and reliability has become the focus of the industry.

The quality and reliability assurance method of semiconductor integrated circuit chips is to ensure that the chip can perform well in various application environments through strict design verification, precise production process control, comprehensive reliability testing, in-depth failure analysis and continuous optimization and improvement. Demonstrate superior performance and stability to meet customers’ demanding needs.

This article will conduct a detailed study and analysis of quality and reliability assurance methods for semiconductor integrated circuit chips.

Semiconductor integrated circuit chip quality assurance

- Design verification: During the design phase, the correctness of the design is verified through simulation and testing. Use high-precision models and simulation tools to simulate circuit behavior under actual working conditions to ensure the functionality and stability of the design.

- Process control: During the manufacturing process, process parameters are strictly controlled to ensure that each step of the process meets the preset standards. This includes temperature, pressure, time, chemical concentration, etc. to reduce errors in the manufacturing process and improve chip consistency and reliability.

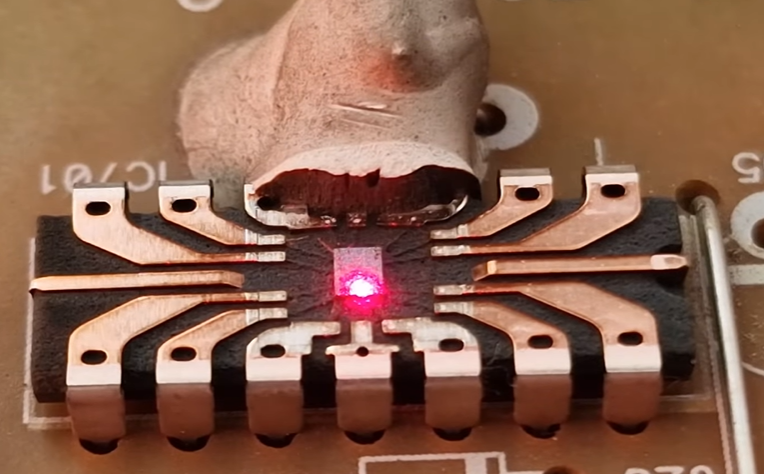

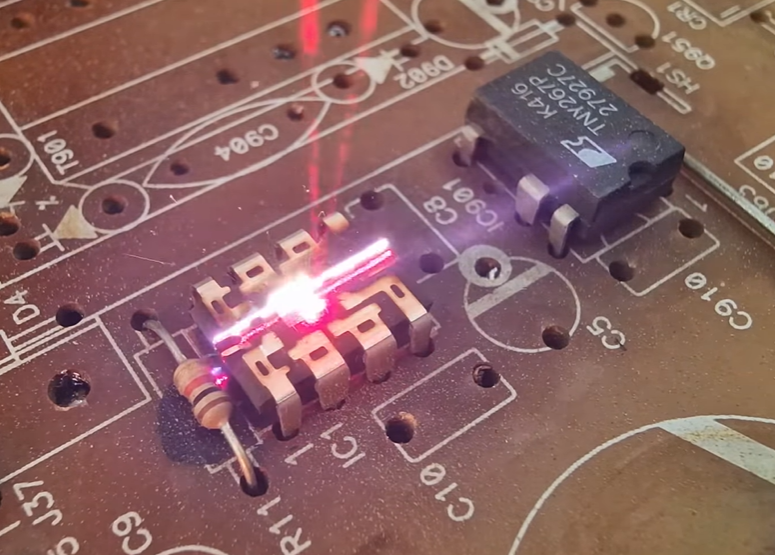

- Defect detection and control: Use non-destructive testing technology, such as X-ray testing, acoustic testing, etc., to conduct comprehensive defect detection on the chip. In addition, by improving the manufacturing process and introducing defect repair technology, the defect density in the chip is reduced, thereby improving its reliability.

- Packaging and testing: Use high-quality packaging materials and advanced testing technology to ensure that the chip is not damaged during the packaging and testing process. During the testing phase, all functions and performance indicators should be covered to ensure that each chip can meet the design requirements.

Semiconductor integrated circuit chip reliability guarantee

- Environmental adaptability design: For different application scenarios, consider the impact of temperature, humidity, mechanical stress and other factors on the chip. Environmental adaptability design is carried out in the design stage so that the chip can work stably in various harsh environments.

- Fault-tolerant and redundant design: In order to improve the reliability of the chip, fault-tolerant and redundant design can be adopted. For example, through multiple redundant structural designs, when some circuits fail, other parts can still continue to work, thus improving the reliability of the system.

- Reliability assessment and life prediction: Predict and evaluate the life and reliability of the chip by establishing mathematical models and simulation tools. This helps to detect potential problems in advance and take appropriate measures for improvement and optimization.

- Failure analysis: Conduct in-depth failure analysis on the failed chip to find out the root cause of the failure and take corresponding measures to improve it. In addition, failure analysis can provide valuable feedback and suggestions for design, manufacturing and testing.

- Reliability engineering: Implement reliability engineering throughout the entire chip life cycle. From design, manufacturing, packaging to testing, reliability evaluation and control must be carried out at every stage. Through continuous improvement and optimization, the reliability level of the chip is continuously improved.

Which semiconductor integrated circuit chip manufacturers use these two methods

Many well-known semiconductor integrated circuit chip manufacturers adopt quality assurance and reliability assurance methods to ensure the quality and reliability of their products. Here are some well-known vendors using these methods:

- TSMC: As the world’s largest semiconductor foundry, TSMC adopts strict quality and reliability assurance methods in the production process to ensure the performance and reliability of its products.

- Intel: As one of the world’s leading semiconductor manufacturers, Intel adopts advanced quality and reliability assurance methods in its products to ensure the long-term stability and reliability of its products.

- Qualcomm: As one of the world’s leading mobile phone chip suppliers, Qualcomm has adopted strict quality and reliability assurance methods in its products to ensure the performance and reliability of its products.

- Texas Instruments(TI): As one of the world’s leading analog chip suppliers, Texas Instruments adopts strict quality and reliability assurance methods in its products to ensure the performance and reliability of its products .

These manufacturers are just one of many using quality assurance and reliability assurance methods. As the semiconductor industry continues to develop, more and more manufacturers are beginning to pay attention to these methods to ensure the quality and reliability of their products.

Differences in Quality and Reliability Assurance Methods for Semiconductor Integrated Circuit Chips

There are some differences in the quality and reliability assurance methods of semiconductor integrated circuit chips.

Quality assurance methods focus primarily on measurement of product performance and compliance with specifications. This typically includes testing and verification during design and manufacturing to ensure that the product meets expected performance indicators within specifications. The goal of quality assurance methods is to ensure that a product conforms to design requirements and meets performance standards throughout its life cycle.

Reliability assurance methods focus more on the product’s ability to maintain performance over time. This involves testing and evaluation of product durability, such as life testing under various environmental conditions, failure mode and effects analysis (FMEA), etc. The goal of the reliability assurance method is to ensure that the product will not fail and meet reliability standards during its expected life.

In general, quality assurance methods focus on the performance of the product at the current stage, while reliability assurance methods focus on the reliability of the product over a period of time. Both methods are designed to ensure that the quality and performance of semiconductor integrated circuit chips meet expected requirements, but the focus and methods are different.

Which method is more suitable for improving the reliability of semiconductor integrated circuit chips

For improving the reliability of semiconductor integrated circuit chips, quality assurance and reliability assurance methods are both important means, but each has its own emphasis.

Quality assurance methods mainly focus on quality control in product design and manufacturing processes, and ensure the quality and reliability of each link through strict production process management and testing.

This approach focuses on prevention, that is, identifying problems during the manufacturing process and correcting them in time to avoid problems from occurring.

The reliability assurance method pays more attention to the durability and long-term stability of the product, and evaluates the performance and reliability of the product under various environmental conditions through life testing, failure mode and effect analysis and other means. This approach focuses on identifying problems and taking steps to improve them to increase product reliability.

In practical applications, quality assurance and reliability assurance methods are not mutually exclusive, but rather complementary. Manufacturers can adopt a comprehensive approach, combining quality assurance and reliability assurance methods, to comprehensively improve product quality and reliability in all aspects from design, manufacturing, testing to maintenance. Such a comprehensive approach can better meet customer needs and improve product competitiveness, and is a more suitable solution for improving the reliability of semiconductor integrated circuit chips.

Summary of integrated circuits

With the continuous development of semiconductor integrated circuit technology, how to ensure its quality and reliability has become the focus of the industry. Only through the comprehensive use of various quality assurance and reliability assurance methods and comprehensive control and management of all aspects from design, manufacturing, packaging to testing can the quality and reliability of semiconductor integrated circuit chips be ensured.

In the future, as technology advances and application requirements continue to increase, the quality and reliability of semiconductor integrated circuits will face greater challenges. Therefore, continuous research and exploration of new quality and reliability assurance methods are of great significance to promote the development of semiconductor integrated circuit technology.

Quality and Reliability Outlook for Semiconductor Integrated Circuits

With the development of emerging technologies such as 5G, Internet of Things, and artificial intelligence, the application scenarios of semiconductor integrated circuits will become more extensive and complex.

This not only puts forward higher requirements for the quality and reliability of semiconductor integrated circuits, but also brings new opportunities and challenges to quality and reliability assurance methods.

In the future, we look forward to achieving more breakthroughs and innovations in the quality and reliability assurance of semiconductor integrated circuits.