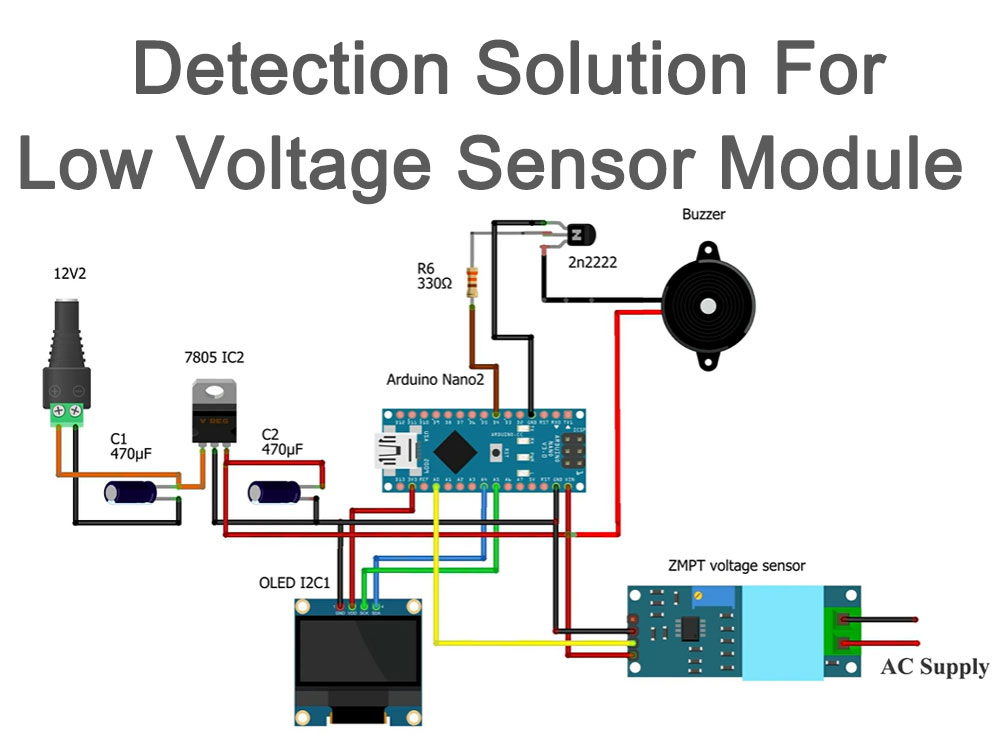

The low-voltage sensor module testing solution is a set of systematic and standardized testing processes, aiming to ensure that the module performance meets standards and has high reliability.

Through multiple tests such as environmental adaptability testing and electrical performance testing, the various indicators of the module are comprehensively evaluated to provide Provide a strong basis for product optimization.

Introduction

With the continuous development of industrial automation and intelligence, low-voltage sensor modules have been widely used in various equipment and systems.

In order to ensure the performance and quality of low-voltage sensor modules, it is crucial to develop an effective detection program.

This solution aims to conduct a comprehensive and accurate detection of the low-voltage sensor module to ensure its normal and stable operation.

Testing purpose

- Verify whether the performance indicators of the low-voltage sensor module meet the design requirements;

- Test the performance of the low-voltage sensor module under actual working conditions;

- Discover potential problems and failures of low-voltage sensor modules and reduce product repair rates;

- Provide a basis for quality assessment and continuous improvement of low-voltage sensor modules.

Detection content and methods

Appearance inspection

Observe the appearance of the low-voltage sensor module and check whether there is damage, deformation, stains, etc., and whether the markings are clear and accurate.

Dimensional measurement

Use measuring tools to measure the critical dimensions of the low-voltage sensor module to ensure that it meets the design requirements.

Electrical performance test

Input voltage range test

Test whether the low-voltage sensor module can work normally within the specified input voltage range;

Output accuracy test

Pass the standard signal source input signal, measure the output signal of the low-voltage sensor module, and calculate its accuracy;

Response time test

When the input signal changes, measure the time it takes for the output signal of the low-voltage sensor module to change.

Environmental adaptability test

Temperature test

Test the performance of the low-voltage sensor module under different temperature conditions (such as -20°C, 25°C, 65°C, etc.);

Humidity test

Test the performance of the low-voltage sensor module under different humidity conditions;

Vibration test

Conduct a vibration test on the low-voltage sensor module to detect its anti-vibration performance.

Functional test

According to the specific functions of the low-voltage sensor module, simulate the actual working scenario and test its various functions.

Reliability test

Test the reliability of the low-voltage sensor module through accelerated life tests, fatigue tests and other methods.

Testing process and steps

- Prepare testing equipment and environment to ensure compliance with testing requirements;

- Carry out appearance inspection and dimensional measurement, and record the inspection results;

- Conduct electrical performance tests and record various parameter indicators;

- Conduct environmental adaptability testing and record performance;

- Conduct functional tests to verify the normality of various functions;

- Conduct reliability testing to evaluate product life and reliability;

- Analyze and evaluate the test results and form a test report;

- According to the test report, unqualified products are processed, and qualified products are marked and stored in the warehouse.

Test report and summary

After completing the inspection of the low-voltage sensor module, a detailed inspection report should be prepared. The report should include the following:

- Testing purposes and requirements;

- Test content and methods;

- Detection process and steps;

- Test results and analysis;

- Conclusion and recommendations.

Through the implementation of this solution, the low-voltage sensor module can be comprehensively and accurately tested to ensure that its performance and quality meet the requirements.

At the same time, this solution can also provide basis and suggestions for the continuous improvement and optimization of low-voltage sensor modules.

In practical applications, the solution can be adjusted and optimized according to specific circumstances to better meet actual needs.

What are the commonly used testing equipment for low-voltage sensor modules?

Commonly used testing equipment for low-voltage sensor modules include the following:

- Signal source: used to provide standard signals to test the output accuracy and response time of the low-voltage sensor module.

- Oscilloscope: used to measure and observe the output signal of the low-voltage sensor module to evaluate its performance.

- Power supply: Provide stable DC or AC power to test the performance of the low-voltage sensor module under different input voltages.

- Environmental chamber: used to simulate different temperature and humidity environments for environmental adaptability testing.

- Vibration table: used to simulate a vibration environment to test the anti-vibration performance of the low-voltage sensor module.

- Data acquisition and analysis system: used to collect and analyze test data of low-voltage sensor modules in order to quantitatively evaluate their performance.

- Calibration equipment: used to calibrate testing equipment and tools to ensure the accuracy and reliability of testing results.

These devices are commonly used tools in low voltage sensor module testing, and which device is used depends on the testing needs and requirements.

When selecting testing equipment and tools, ensure that their accuracy, reliability and applicability meet the testing requirements.

What testing tools need to be included in the testing solution for low-voltage sensor modules?

The detection solution for the low-voltage sensor module needs to include the following detection tools:

- Voltage test tool: such as a multimeter, used to measure whether the output voltage of the low-voltage sensor module is within the normal range.

- Current testing tools: such as ammeters, used to test whether the output current is normal and whether it meets the relevant parameters of the sensor.

- Internal resistance test tool: such as a multimeter or independent resistance meter, used to test whether the output resistance of the low-voltage sensor module is correct and stable.

- Environmental adaptability testing equipment: such as temperature chambers, humidity chambers and shaking tables, etc., used to simulate different environmental conditions and test the performance of low-voltage sensor modules.

- Signal source and oscilloscope: used to provide standard signals and measure the output signal of the low-voltage sensor module to evaluate its accuracy and response time.

- Calibration equipment: used to calibrate testing equipment and tools to ensure the accuracy and reliability of testing results.

These tools are commonly used equipment in low-voltage sensor module testing. According to the specific testing needs and requirements, the corresponding equipment and tools can be selected for testing.

When selecting testing tools, ensure that their accuracy, reliability and applicability meet the testing requirements.

Low voltage sensor module testing FAQs

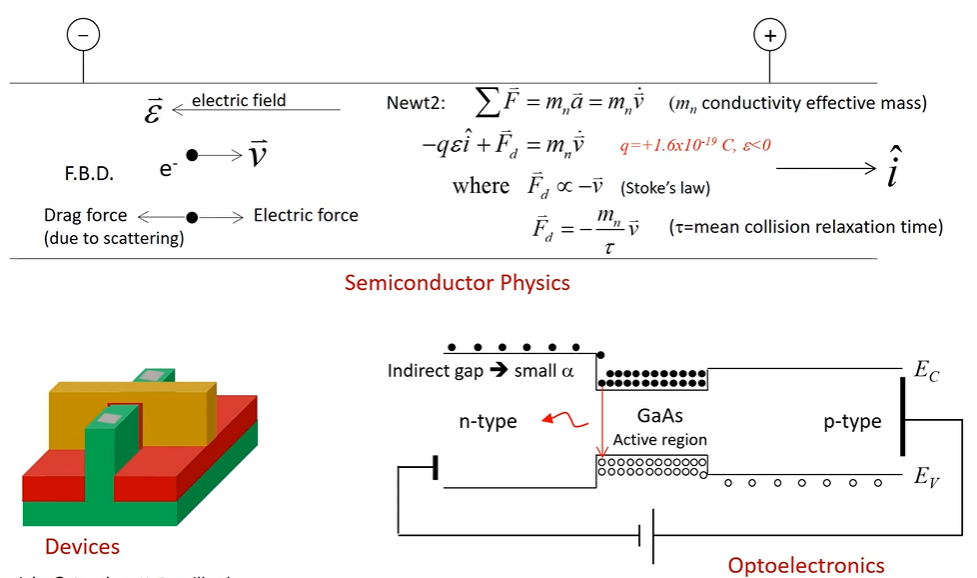

The low-pressure sensor module is an electronic component used to measure low-voltage, weak electrical signals. It can sense pressure changes of liquids, gases, solids and other substances and convert them into electrical signal output.

Low-voltage sensor modules are widely used in industrial automation and intelligence. It is crucial to detect their performance and quality to ensure their normal and stable operation, reduce product repair rates, and provide a basis for continuous improvement.

Electrical performance testing includes input voltage range testing, output accuracy testing, response time testing, etc. Input the signal through the standard signal source, measure the output signal of the low-voltage sensor module, calculate its accuracy, and observe the response time.

The testing content of low-voltage sensor modules mainly includes appearance inspection, dimensional measurement, electrical performance testing, environmental adaptability testing and functional testing, etc.

The environmental adaptability test includes temperature test, humidity test and vibration test, etc. It is designed to detect the performance of the low-voltage sensor module under different environmental conditions to ensure that it can work normally in various environments.

Test the performance of the low-voltage sensor module under different stress conditions and evaluate its reliability through accelerated life tests, fatigue tests and other methods.

During the testing process, you need to pay attention to preventing overloading, preventing static electricity, ensuring good grounding, etc. to ensure the accuracy and reliability of the testing results. At the same time, relevant safety regulations and operating procedures should be followed to ensure the safety of personnel and equipment.