How to make a temperature sensor element?

Manufacturing temperature sensor components refers to the process of designing and actually manufacturing temperature sensors. This involves selecting appropriate materials, such as thermistors, semiconductors, etc., and performing processing according to design requirements, such as thin film deposition, photolithography, etc., to form the required component structure.

It is then packaged and tested to ensure its accuracy and stability. Modern temperature sensor component manufacturing also includes the use of automated equipment and advanced processes such as surface mount technology and cleanliness control to ensure quality and efficiency in mass production.

The process of manufacturing a temperature sensor element includes the following steps:

Material preparation

According to the sensor type and requirements, the corresponding materials are selected and preprocessed, such as platinum wire drawing and purification.

Component processing

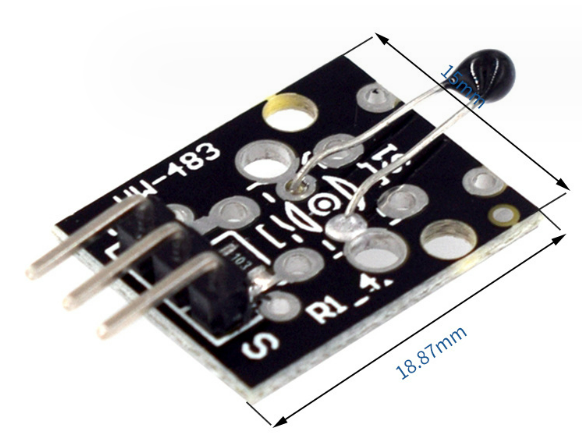

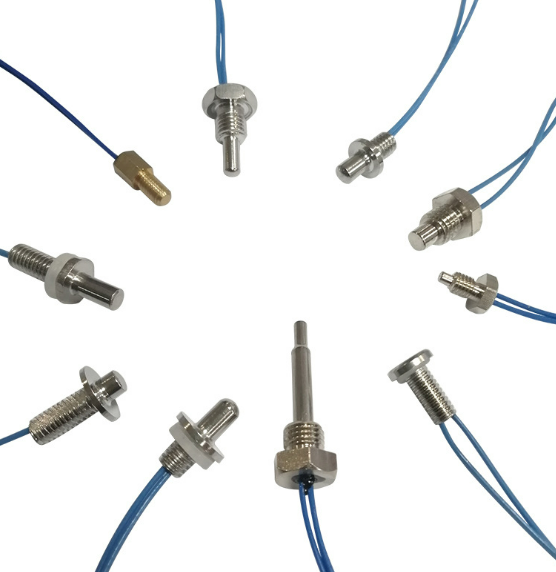

According to the design requirements, the material is cut, bent, etched and other processing steps are performed to produce components that conform to the shape and structure of the sensor.

Component assembly

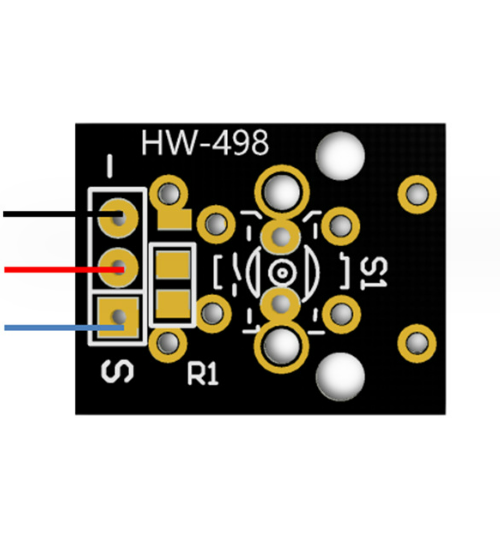

Assemble the processed components and connect them with circuit boards, connecting wires and other components to form a complete temperature sensor.

Please note that these steps are just a general process for manufacturing a temperature sensor element and the actual manufacturing process may vary depending on the specific sensor type and design requirements. During the manufacturing process, some auxiliary operations need to be performed according to specific needs, such as ceramic shell packaging, circuit board welding, etc.

What qualifications does a factory that manufactures temperature sensor components have?

Factories that manufacture temperature sensor components need to have the following qualifications:

Production License

Factories need to obtain corresponding production licenses to ensure that they have the manufacturing capabilities and conditions to comply with national laws and regulations.

Quality management system certification

The factory needs to establish a complete quality management system and pass ISO 9001 and other quality management system certifications to ensure that it has a scientific and standardized management system in product development, raw material procurement, production process control, product inspection, etc.

certified product

As an important sensor product, temperature sensor components need to comply with relevant product standards and quality requirements. Factories need to have corresponding product certifications, such as CE certification, RoHS certification, etc., to ensure that their products comply with national and international standards.

Technical strength

Manufacturing temperature sensor components requires certain technical strength and R&D capabilities. The factory needs to have a professional technical team and advanced production equipment, as well as technology research and development and innovation capabilities in related fields.

Environmental protection and safety certification

Factories need to comply with national and local environmental protection and safety regulations, establish corresponding environmental protection and safety management systems, and obtain corresponding environmental protection and safety certifications to ensure their environmental protection and safety performance during the production process.

Factories that manufacture temperature sensor components need to have corresponding production licenses, quality management system certifications, product certifications, technical strength, environmental protection and safety certifications and other qualifications to ensure that they have the ability and conditions to manufacture high-quality, high-performance temperature sensor components.

What issues need to be paid attention to when manufacturing temperature sensors?

When manufacturing temperature sensors, you need to pay attention to the following issues:

Accuracy and stability

The accuracy and stability of the temperature sensor have a great impact on its measurement results. During the manufacturing process, it is necessary to ensure that the output signal of the sensor is proportional to the temperature change, and at the same time, measures should be taken to improve the stability of the sensor, such as using high-quality materials and advanced manufacturing processes.

Sensitivity and response time

The sensitivity and response time of the temperature sensor are also very important parameters. Appropriate materials and design structures should be selected to improve the sensitivity of the sensor and shorten the response time as much as possible to monitor temperature changes in real time.

Usage environment

The usage environment of the temperature sensor also has a great impact on its measurement results. For example, sensors operating in high-temperature environments need to be able to withstand high temperatures while also considering their impact on environmental factors. Therefore, during the manufacturing process, the impact of the use environment on the sensor must be fully considered and corresponding measures must be taken.

Protective measures

In some application scenarios, the temperature sensor needs to have certain protective capabilities, such as waterproof, dustproof, etc. Therefore, during the manufacturing process, corresponding protective measures need to be taken according to specific application scenarios to protect the sensor from external environmental factors.

Cost and maintainability

In addition to performance and quality, the cost and maintainability of temperature sensors are also issues that need to be considered. The manufacturing cost of the sensor should be kept as low as possible while ensuring that the sensor is easy to maintain and replace so that it can be calibrated or replaced when needed.

In short, manufacturing temperature sensors requires attention to many aspects such as accuracy, stability, sensitivity, response time, use environment, protective measures, cost and maintainability. Only by comprehensive consideration and appropriate measures can we create high-quality, high-performance temperature sensors.

What are the application scenarios of temperature sensor elements?

The application scenarios of temperature sensor components are very wide. The following are some common application scenarios:

automated industry

In the field of industrial automation, temperature sensors are widely used in various industrial equipment, such as boilers, chemical reactors, plastic machines, etc., to monitor and control the temperature of the equipment to ensure its normal operation.

Car manufacturer

During the automobile manufacturing process, temperature sensors are used to monitor the temperature of systems such as engines, transmissions, and brakes to ensure vehicle safety and performance.

medical equipment

Temperature sensors used in medical devices require high accuracy, stability and biocompatibility. For example, temperature sensors can be seen in infrared thermometers, medical hot and cold compress therapy devices and other equipment.

Home appliance

In home appliances, temperature sensors are used to control and monitor the temperature of home appliances, such as air conditioners, refrigerators, ovens, etc.

Environmental monitoring

In the field of environmental monitoring, temperature sensors are used to monitor environmental temperature, humidity and other parameters, such as weather stations, greenhouses and other places.

Aerospace

In the aerospace industry, temperature sensors are used to monitor the temperature outside and inside aircraft to ensure their safety and performance.

scientific research

In scientific research, temperature sensors are used to study the thermal properties of substances, chemical reactions, etc., such as calorimeters, chemical reactors and other equipment.

Temperature sensor components have a wide range of application scenarios, involving industry, medical care, home appliances, environmental monitoring, aerospace and other fields.