Vacuum circuit breaker switching capacitor current aging test

The vacuum circuit breaker switching capacitor current aging test is an important test for the performance of the vacuum circuit breaker.

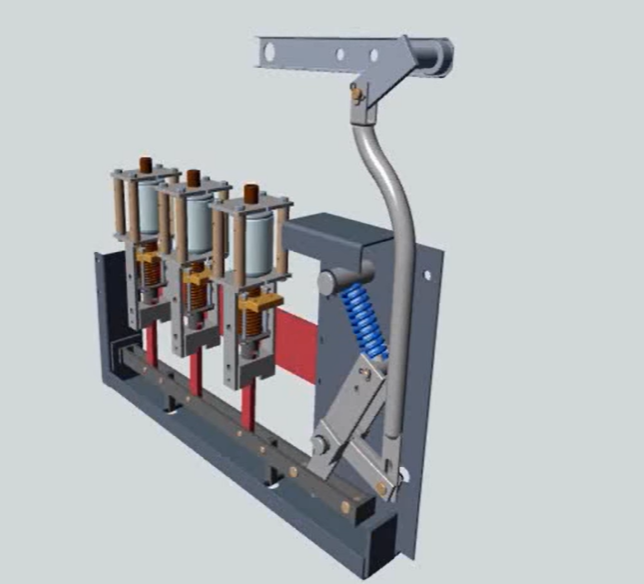

Vacuum circuit breakers are widely used in power systems, mainly for control and protection circuits. In the switching capacitor current aging test, the vacuum circuit breaker needs to undergo multiple opening and closing operations to test the stability and reliability of its performance.

Test purposes

The purpose of the switching capacitor current aging test is to test the performance of the vacuum circuit breaker under multiple switching operations, especially the performance when switching capacitor current.

Through this test, changes in the mechanical, electrical and thermal properties of the circuit breaker after multiple operations can be discovered and evaluated to ensure its stability and reliability during long-term use.

Test principle

The capacitor current aging test is based on the basic principles of capacitors. In power systems, capacitors are common reactive power compensation devices used to improve the power factor of the system, reduce line losses and improve the voltage quality of the power grid. When a vacuum circuit breaker switches capacitor current, it needs to withstand higher current and voltage. Through multiple opening and closing operations, the performance of the vacuum circuit breaker under high current and high voltage can be tested.

Experiment procedure

- Preparation stage: Select a suitable vacuum circuit breaker, install and wire it according to regulations. Prepare appropriate power supplies, measuring instruments and auxiliary equipment.

- Initial testing: Before starting the test, perform an initial testing on the mechanical, electrical and thermal properties of the vacuum circuit breaker to establish reference data.

- Set conditions: Set power parameters, including voltage, current and frequency, to meet the charging and discharging needs of the capacitor. Set the operating conditions of the vacuum circuit breaker, such as the number of operations, interval time, etc.

- Test operation: Carry out multiple opening and closing operations according to the set conditions, and monitor various performance parameters of the vacuum circuit breaker in real time.

- Data recording: Record in detail the performance parameters after each operation, such as mechanical characteristics, electrical characteristics and thermal characteristics, etc.

- Result analysis: Compare the initial detection data with the data after the test, and analyze the performance changes of the vacuum circuit breaker after multiple opening and closing operations.

- Evaluation and reporting: Based on the analysis results, evaluate the performance level of the vacuum circuit breaker and write a detailed test report.

Precautions

- Safety first: Since the capacitor current may be very high, appropriate safety measures should be taken during testing, such as wearing protective clothing, using insulated tools, etc.

- Accuracy requirements: During the test process, high-precision measuring instruments should be used to ensure the accuracy and reliability of the data.

- Comply with regulations: When conducting tests, relevant national and industry standards should be observed to ensure test compliance.

- Preventive measures: During the test, pay close attention to the status changes of the vacuum circuit breaker, and handle any abnormalities in time.

- Complete records: All data and phenomena during the test should be recorded in detail for subsequent analysis and evaluation.

- Environmental protection: After the test, the waste generated should be disposed of in accordance with relevant regulations to ensure that the impact on the environment is minimized.

- Personnel training: Personnel conducting the test should receive professional training, be familiar with relevant equipment and operating procedures, and have necessary safety awareness and skills.

- Equipment maintenance: Regularly maintain and maintain the test equipment to ensure its normal operation and service life.

- Summary and improvement: Based on the test results and evaluation reports, summarize experience and lessons, put forward improvement measures and suggestions, and continuously improve the performance and quality of vacuum circuit breakers.

In short, the vacuum circuit breaker switching capacitor current aging test is an important test task and is of great significance to ensure the reliability and stability of the vacuum circuit breaker.

During the test process, relevant regulations and standards should be strictly followed to ensure the accuracy and reliability of the test results.

At the same time, strengthening personnel training and equipment maintenance are also important measures to ensure the smooth progress of the test.

Frequently asked questions and solutions

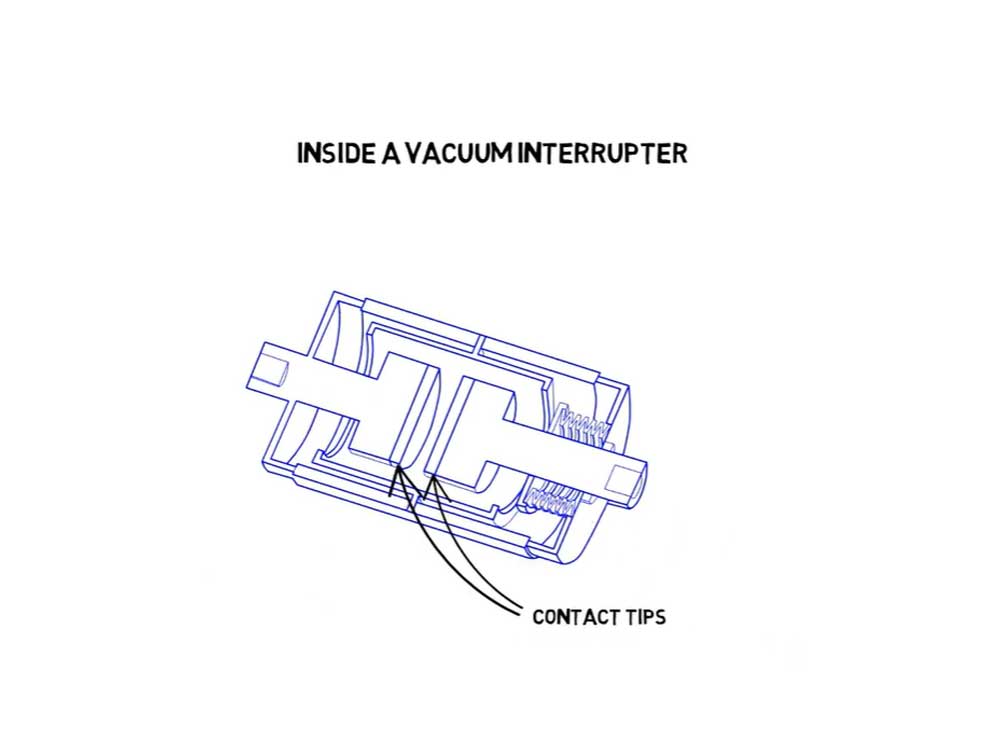

- Circuit breaker contacts worn: After multiple opening and closing operations, the circuit breaker contacts may become worn. This may lead to poor contact contact, increase contact resistance, and affect the performance of the circuit breaker. Solution: Check and replace the contacts regularly to ensure that the smoothness and material of the contact surface meet the requirements.

- Mechanical structure loose: After multiple operations, the mechanical structure of the circuit breaker may become loose, affecting the accuracy and reliability of its action. Solution: Regularly inspect and tighten mechanical components to ensure they are solid and reliable.

- Degradation of insulation performance: After switching on and off high voltages and large currents for many times, the insulation material of the circuit breaker may age, resulting in a decrease in insulation performance. Solution: Regularly check and replace insulation materials to ensure that their electrical performance meets requirements.

- Unstable thermal performance: After multiple operations, the thermal performance of the circuit breaker may change, affecting its normal operation. Solution: Strengthen the heat dissipation design, clean the heat dissipation channel regularly, and ensure that the circuit breaker works at normal temperature.

- Operating mechanism stuck: The operating mechanism may get stuck after multiple operations, affecting the normal operation of the circuit breaker. Solution: Lubricate the operating mechanism regularly to ensure flexible movement.

Future outlook

With the continuous advancement of science and technology and the increasing complexity of power systems, the performance requirements for vacuum circuit breakers are becoming higher and higher. In the future, switching capacitor current aging tests will pay more attention to the application of intelligent and automated technologies.

By introducing advanced sensors and detection equipment, real-time monitoring and automatic control of the test process can be achieved, improving the accuracy and reliability of the test. At the same time, with the development of big data and cloud computing technology, the processing and analysis of test data will be more in-depth and comprehensive, helping to better evaluate the performance of vacuum circuit breakers and discover potential problems.

In summary, the vacuum circuit breaker switching capacitor current aging test is an important means to ensure the performance of the vacuum circuit breaker.

By strictly abiding by test regulations and standards, strengthening personnel training and equipment maintenance, the accuracy and reliability of the test can be ensured.

At the same time, taking corresponding solutions to common problems in the test can further improve the performance and quality of the vacuum circuit breaker. In the future, with the introduction of intelligent and automated technologies, the switching capacitor current aging test will be more efficient and accurate, providing a strong guarantee for the stable operation of the power system.

FAQs

The burn-in test is a method of simulating the actual operating operation of a vacuum circuit breaker, especially when switching capacitor currents. In this way, the performance and reliability of vacuum circuit breakers can be tested and evaluated.

In practical applications, vacuum circuit breakers may undergo frequent switching operations, especially when switching capacitive currents. In order to ensure the stability and reliability of the vacuum circuit breaker, aging tests are required to simulate actual operating conditions and test its performance.

a. Unstable opening and closing operation: The vacuum circuit breaker may exhibit unstable operation when opening and closing the capacitor current. This may be due to problems in structural design or manufacturing process.

b. Contact ablation: When switching capacitor current, if the contact design of the vacuum circuit breaker is unreasonable or the material selection is inappropriate, contact ablation may occur.

c. Mechanical structure wear: Frequent opening and closing operations may cause wear and tear on the mechanical structure, thereby affecting the life and reliability of the vacuum circuit breaker.

d. Electromagnetic interference problem: When switching capacitor current, electromagnetic interference may be generated, affecting the normal operation of surrounding equipment.

a. Optimize structural design: Optimize the structure of the vacuum circuit breaker, especially the design of the contacts and mechanical structure, to improve its stability and reliability.

b. Improve manufacturing process: Use advanced manufacturing processes and technologies to ensure that the manufacturing quality of vacuum circuit breakers meets requirements.

c. Enhance material selection: Select materials suitable for switching capacitor current to reduce the possibility of contact ablation.

d. Enhance anti-interference capability: Reduce the generation of electromagnetic interference by improving design and adopting appropriate filtering technology.

The results of the aging test are evaluated according to actual needs and standards. The performance of a vacuum circuit breaker can be evaluated by comparing test data with expected results. In addition, the competitiveness of the vacuum circuit breaker can be evaluated by comparing its performance with other similar products.

a. Use high-precision testing equipment: More accurate data can be obtained by using high-precision testing equipment.

b. Standardized operating procedures: Ensure the standardization and standardization of test operations to obtain consistent results.

c. Regular calibration of equipment: Calibrate test equipment regularly to ensure its accuracy.

d. Strengthen personnel training: Provide training to test personnel to improve their skills and accuracy.

With the continuous advancement of technology, the future development trends of vacuum circuit breaker switching capacitor current aging tests may include: more efficient testing methods, higher-precision testing equipment, more intelligent data analysis systems, etc. These development trends will help improve the efficiency and accuracy of testing and better evaluate the performance and reliability of vacuum circuit breakers.