Precision components refer to electronic components with high precision, good stability, and high reliability. They are usually used in circuits, systems, and instruments that require high precision.

Compared with ordinary components, precision components require higher precision and better stability, and can maintain relatively stable electrical parameters and mechanical properties in the working environment.

Common precision components include resistors, capacitors, inductors, transistors, integrated circuits, etc. These components have the characteristics of simple structure, clear principle, reliable performance and long service life.

The meaning of precision electronics

It refers to electronic products or components that are manufactured with very high precision and very small errors. In the machinery and electronics industries, the word precision is usually used to describe products or components that require extremely high precision, complex manufacturing processes, and require the use of advanced production equipment and testing methods to ensure product quality and stability.

Main feature

The main characteristics of precision electronic components include high precision, high reliability, high stability, high consistency, low noise and low power consumption.

Types of precision electronic components

There are many types of precision electronic components, which can be roughly divided into the following categories according to their functions and uses:

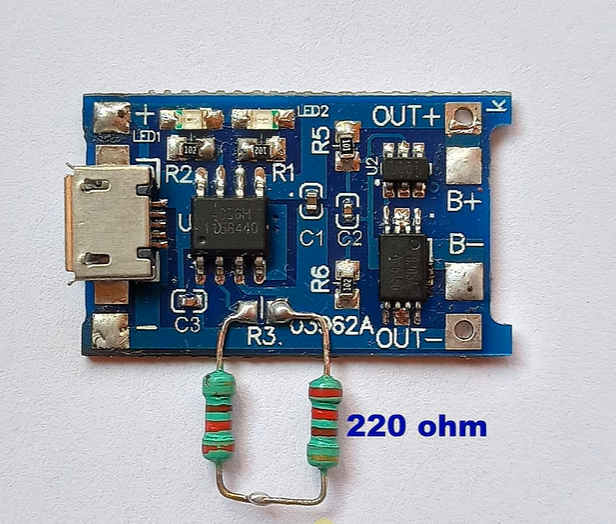

- Resistor: A resistor is a device used to control electrical transmission, mainly used to control current, voltage and power. According to different materials, they can be divided into carbon film resistors, metal film resistors, thermistors, etc. Among them, carbon film resistors have the characteristics of high precision and good stability, and are often used in precision measurement, circuit calibration and other fields.

- Capacitor: A capacitor is a device used to store and release charges. It is mainly used to regulate voltage and current. It can be divided into ceramic capacitors, dielectric capacitors, ohmic capacitors, etc. according to materials. Among them, ceramic capacitors have the characteristics of fast frequency response and electrical stability, and are usually used in high-precision circuits such as electronic computers and navigation systems.

- Inductor: An inductor is a component that can store magnetic field energy and is mainly used in circuits such as filtering, oscillation, and voltage transformation. Precision inductors have the characteristics of high precision, high Q value, and low loss, and are widely used in communications, radar, medical electronics and other fields.

- Diodes and transistors: Diodes and transistors are semiconductor devices with functions such as amplification, switching, and voltage stabilization. Precision diodes and transistors have the characteristics of low power consumption, high speed, and high reliability, and are widely used in integrated circuits, power electronics and other fields.

- Sensor: A sensor is a device that can convert physical quantities into electrical signals, such as pressure sensors, temperature sensors, photoelectric sensors, etc. Precision sensors have the characteristics of high precision, high sensitivity, and high stability, and are widely used in automation, robotics, aerospace and other fields.

In addition to the above types of components, there are many other types of precision electronic components, such as filters, oscillators, crystal oscillators, field effect transistors, etc. These components play an important role in their respective fields and provide a solid foundation for the development of modern electronic technology.

How to Make Precision Electronic Components

Manufacturing precision electronic components requires the use of a series of advanced processes and technologies, including microelectronics manufacturing technology, precision processing technology, thin film deposition technology, photolithography and etching technology, etc. These technologies can produce high-precision and high-stability electronic components at the nanometer level to meet various complex and precise application requirements.

Specifically, microelectronics manufacturing technology is a manufacturing technology that integrates microelectronic devices, circuits and systems on a chip. It includes integrated circuit manufacturing, micro-nano device manufacturing, thin film manufacturing and other aspects, and is one of the core technologies for manufacturing precision electronic components.

Precision machining technology is a technology for manufacturing mechanical components and structures with high precision, high surface quality, and high stability. It includes micro-cutting, grinding, grinding, polishing and other processes, which can process very fine and complex mechanical parts.

Thin film deposition technology is a technology that deposits thin film materials on the surface of a substrate. It includes physical vapor deposition, chemical vapor deposition and other methods, which can prepare thin film materials with high purity, high density and high adhesion. It is one of the important processes for manufacturing precision electronic components.

Photolithography and etching technologies are key technologies for manufacturing integrated circuits and micro-nano devices. Photolithography is to irradiate the designed circuit pattern onto the photosensitive material through a light beam to cause a chemical reaction to form a copy of the circuit pattern; etching is to use the copied circuit pattern to change the circuit pattern from the chemical reaction or physical impact. The base material is peeled off to form the actual circuit.

In addition to the above technologies, manufacturing precision electronic components also requires the use of a series of auxiliary processes and technologies, such as electroplating, coating, heat treatment, etc. These processes and technologies can improve the electrical performance, mechanical performance and environmental adaptability of components, thereby improving the reliability and stability of components.

In short, manufacturing precision electronic components requires the use of a series of high-precision processes and technologies, which requires a high degree of specialization and technology accumulation. At the same time, it is also necessary to continuously introduce new technologies and develop new products to meet the growing market demand.

Manufacturing Equipment

Precision electronic component manufacturing equipment mainly includes the following categories:

- Manufacturing equipment: such as printing machines, placement machines, welding machines, cutting machines, etc., used to manufacture and assemble electronic components. These devices require high precision and stability to ensure that the electronic components manufactured meet the requirements.

- Testing equipment: such as testing machines, microscopes, oscilloscopes, etc., used to test the performance and quality of electronic components. These devices require high precision and sensitivity to ensure the accuracy and reliability of detection results.

- Auxiliary equipment: such as cleaning machines, dryers, coating machines, etc., used to assist in the manufacturing and testing of electronic components. These devices require high precision and efficiency to ensure the quality and production efficiency of electronic components.

These equipment need to have high precision, high stability, high reliability and other characteristics to meet the manufacturing and testing requirements of precision electronic components.

In addition, with the continuous advancement of technology and increasing application requirements, manufacturing equipment is also constantly developing and innovating to adapt to new manufacturing processes and higher performance requirements.

Application areas

- Communication field: Precision electronic components are used to manufacture communication equipment, optical communication devices, mobile communication base stations, etc., supporting high-speed data transmission and signal processing.

- Automotive electronics field: Precision electronic components are used in automobile control systems, sensors, actuators, etc. to improve the safety, comfort and fuel economy of automobiles.

- Computer and network fields: Precision electronic components are indispensable components for manufacturing computer processors, memory modules, network equipment, etc., supporting the computing and data transmission of computers and networks.

- Digital audio and video field: Precision electronic components are used in high-definition video processing, audio processing, etc. to provide high-quality audio-visual experience.

- Aerospace field: Because precision electronic components have the characteristics of high stability and high reliability, they are used to manufacture aerospace equipment, satellite communications, etc.

- Medical electronics field: Precision electronic components are used in medical equipment, such as medical imaging equipment, surgical robots, etc., to improve the level and efficiency of medical services.

These application fields have very high requirements on the performance and quality of precision electronic components, so advanced manufacturing processes and technologies are required to ensure their quality and stability.

At the same time, with the continuous advancement of technology and increasing application requirements, precision electronic components are also constantly developing and innovating to meet the stringent requirements of various fields.

Frequently Asked Questions

Precision electronic components refer to those electronic products or components that are manufactured with very high precision and with very small errors. They have the characteristics of high precision, high stability, and high reliability, and are widely used in various fields that require high performance of electronic components.

There are many types of precision electronic components, including resistors, capacitors, inductors, diodes, transistors, sensors, etc. These components play an important role in their respective fields and provide support for the development of modern electronic technology.

The main difference between precision electronic components and ordinary electronic components is their accuracy and stability. Precision electronic components are manufactured with higher precision, smaller error ranges, and can work stably under more stringent conditions. In addition, the materials and processes of precision electronic components are also more advanced and sophisticated.

Precision electronic components can provide higher circuit performance and more reliable working performance to meet the needs of various complex and precise applications. In many fields, such as communications, medical electronics, aerospace, etc., the performance requirements of electronic components are very high. Precision electronic components must be used to ensure the normal operation and performance of the equipment.

Selecting appropriate precision electronic components requires consideration of multiple factors, including component specifications, performance parameters, accuracy levels, working environment, etc. In addition, it is necessary to select appropriate component types and brands according to specific application requirements, and conduct reasonable circuit design and component layout.

Ensuring the quality and stability of precision electronic components requires the use of advanced manufacturing processes and technologies, as well as strict quality control and testing. In addition, you also need to pay attention to the storage and use environment of components to avoid being affected by adverse factors such as temperature, humidity, and static electricity.