What is an ultrasonic generator?

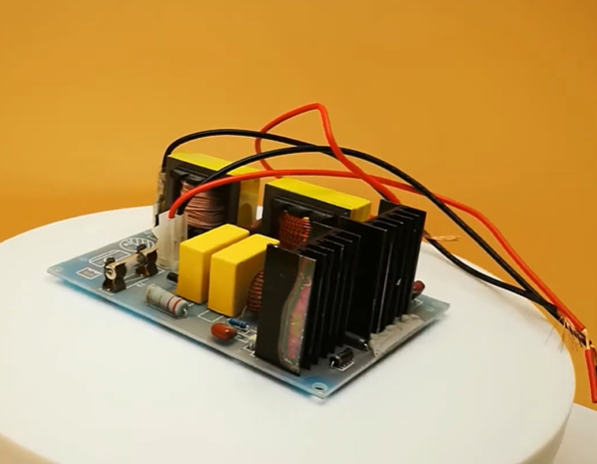

Ultrasonic generator, also known as ultrasonic drive power supply, electrical box, and controller, is an important component of high-power ultrasonic system.

The high-frequency AC signal matched by the ultrasonic generator and the ultrasonic transducer is used to drive the ultrasonic transducer to work.

What is the function of ultrasonic generator

The function of the ultrasonic generator is to convert the mains power into a high-frequency AC signal that matches the ultrasonic transducer and drive the ultrasonic transducer to operate.

High-power ultrasonic power supplies generally use switching power supply circuits in terms of conversion power.

Ultrasonic power supplies are divided into self-excited and other-excited power supplies. The self-excited power supply is called ultrasonic simulation power supply, and the other-excited power supply is called ultrasonic generator.

Working principle of ultrasonic generator

An ultrasonic generator, also known as an ultrasonic power supply or ultrasonic transducer, is a device that converts electrical energy into mechanical energy. It uses the principle of the piezoelectric effect to drive the piezoelectric ceramic material by applying high-frequency AC voltage, causing it to produce mechanical vibrations of the same frequency.

The working principle of the ultrasonic generator can be summarized as follows:

- AC voltage: Ultrasonic generators usually use 220V or 380V AC voltage as input, and convert it into DC voltage through rectification and filtering.

- Oscillator: The oscillator is the core part of the ultrasonic generator. It can be a self-excited oscillator or a self-excited oscillator. The self-excited oscillator generates oscillation through a positive feedback circuit, while the self-excited oscillator requires an external signal source to provide an excitation signal.

- Piezoelectric ceramics: Ultrasonic generators use the piezoelectric effect of piezoelectric ceramics to convert electrical energy into mechanical energy. When piezoelectric ceramics are acted upon by an external electric field, they deform and produce mechanical vibrations.

- Resonance unit: In order for the ultrasonic generator to work properly, it needs to match the impedance and frequency of the ultrasonic resonance unit. The resonant unit usually consists of an adjustable capacitor and a fixed impedance resistor to adjust the resonant frequency and impedance matching.

- Amplifier: Since the amplitude of the transducer output is low, usually only a dozen microns, an amplifier is needed to amplify the amplitude. The amplifier amplifies the mechanical vibration signal output by the transducer so that it has sufficient energy for various applications.

In short, an ultrasonic generator is a device that uses the piezoelectric effect to convert electrical energy into mechanical energy.

Its working principle is to drive the piezoelectric ceramic material by applying high-frequency AC voltage to produce mechanical vibration at the same frequency, and adjust the parameters of the output signal through the resonant unit and amplifier.

What are the types of ultrasonic generators?

There are many types of ultrasonic generators, which can be divided into the following types according to different classification methods:

- According to the working frequency, it can be divided into low frequency (100hz) and medium frequency (100~10mhz) ultrasonic generators.

- According to the energy conversion mode, it can be divided into electromagnetic, piezoelectric ceramic and semiconductor ultrasonic generators.

- According to the output waveform, it can be divided into continuous wave and pulse wave ultrasonic generators.

- According to power, it can be divided into small power, medium power and high power ultrasonic generator.

- According to the circuit structure, it can be divided into self-excited and separately excited ultrasonic generators.

In addition, there are some specific classifications, such as frequency-adjustable ultrasonic generators, 100W/300W ultrasonic generators, low-power ultrasonic generators, high-frequency ultrasonic generators, large-function ultrasonic generators, and digital display ultrasonic generators according to function. Generator etc.

How to judge the quality of ultrasonic generator

The quality of ultrasonic generators is generally judged from the following two points:

- Check whether the output power is constant. We know that when the voltage of the ultrasonic power supply changes. The output power of the ultrasonic power supply will also change. At this time, the mechanical vibration reflected on the ultrasonic transducer will become larger and smaller, causing the cleaning effect to be unstable. Therefore, it is necessary to stabilize the output power and adjust the power amplifier accordingly through the power feedback signal to make the power amplification stable.

- Check whether frequency tracking is efficient. When the ultrasonic transducer works at the resonant frequency point, it has the highest efficiency and the most stable operation. However, the resonant frequency point of the ultrasonic transducer will change due to assembly reasons and aging of the work. Of course, this change is only a frequency drift and does not change. It will be huge. Frequency tracking can control the frequency of the ultrasonic generator to follow the resonant frequency point of the ultrasonic transducer within a certain range. Let the generator always work at its best.

Matching problem between ultrasonic generator and transducer

Among ultrasonic cleaning machines of the same model, if the ultrasonic generator and transducer are well matched and debugged, the cleaning effect will be better; if the ultrasonic generator and transducer are poorly matched and debugged, the cleaning effect will be poor.

For the same ultrasonic system, if the cleaning effect deteriorates after working for a period of time, or the vibration box is replaced, the impedance matching circuit needs to be re-adjusted.

Different from the matching of general electronic equipment, the impedance matching of ultrasonic generators not only solves the problem of rheostat, but also solves the problem of tuning.

At present, most companies conduct matching and debugging based on the personal experience of ultrasonic engineers, and the matching effect also depends on people. different.

In actual application scenarios, some manufacturers found that the ultrasonic wave debugged in the factory was not effective at the customer’s end.

There are also customers asking why their cleaning equipment is running normally, but the cleaning quality of the products is unstable. There are many factors involved, and the failure of the ultrasonic system to match well is one of the important factors.

The matching and debugging of the ultrasonic system is crucial for ultrasonic cleaning equipment, but the current manual matching and debugging method greatly restricts the manufacturing efficiency of the ultrasonic system and the stability of the cleaning equipment.

Analysis of development trends of ultrasonic generators

Develop

The development of ultrasonic generators has gone through four stages:

The first stage: the era of tube generators (before the 1980s);

The second stage: the era of transistor analog generators (1980s and 1990s);

The third stage: the era of switching generators (currently mainstream);

The fourth stage: digital generator era (future trend).

Future trends

With the continuous development of China’s science and technology and the continuous upgrading of industry, ultrasonic technology is also constantly innovating. In the wave of industrial digital transformation, various types of automated cleaning equipment are also undergoing digital upgrades to adapt to the requirements of future digital factories. Ultrasonic generators are about to enter the era of digital generators.

Ultrasonic generators of the future will become simpler, more versatile and smarter. Matching and debugging do not require professionals, anyone can easily achieve it with one click; the compatibility is greatly improved, and one generator can match loads of multiple frequencies and powers; it can be easily connected to the digital network to communicate with cleaning equipment and factory control communication.

More and more cleaning equipment manufacturing companies will tend to use ultrasonic generators with intelligent matching functions, and the pain points of the ultrasonic cleaning industry will also be solved with the development of technology.

Frequently Asked Questions

Before using the intelligent ultrasonic generator, you need to check whether the power cord and plug are intact and confirm that the grounding device has been installed. After plugging in the 220v AC power, turn on the switch and the indicator light should be on. During use, you should pay attention to the changes of the indicator light. When the indicator light changes from red → green → yellow → blue (or flashes), it means normal operation. If any abnormal phenomena occur during use, such as no light, no sound, abnormal vibration, etc., you should immediately turn off the power switch and contact maintenance personnel in time.

When maintaining and repairing intelligent ultrasonic cleaning machines, you need to pay attention to the following aspects: regularly check the tightening of each component and whether the connections are loose; keep the surface of the fuselage clean and dry to prevent the machine from being invaded by corrosive gases; When it is out of service for a long time, the residue in the machine should be cleaned and stored for reuse; pay attention to moisture-proof treatment to prevent unnecessary losses caused by moisture and rust.

Ultrasound is a mechanical wave that attenuates during propagation. In order for ultrasonic waves to be emitted normally, certain protection measures need to be taken on the transducer to extend its service life and working efficiency. The intelligent ultrasonic generator uses the principle of the piezoelectric effect to drive the piezoelectric ceramic material by applying high-frequency AC voltage, causing it to produce mechanical vibrations of the same frequency. At the same time, in order for the ultrasonic generator to work properly, it needs to match the impedance and frequency of the ultrasonic resonance unit.