How do the electronic components on the PCB work?

The working principle of electronic components on PCB boards involves many aspects, including circuit design, signal transmission, electrical connection, and thermal design. These issues will be introduced in detail below.

Electronic component circuit design

Circuit design is the core of the work of electronic components on PCB boards. It determines the connection relationships and signal transmission paths between electronic components. In the circuit design stage, designers need to consider issues such as performance parameters of electronic components, signal stability, and power supply. Usually, circuit design will use professional EDA (Electronic Design Automation) software for drawing and simulation to ensure the correctness and reliability of the design.

Signal transmission processing of electronic components

Signal transmission is the process of communication between electronic components. On the PCB, signals are transmitted through wires and connectors. The transmission speed of a wire is related to factors such as the material, diameter and laying method of the wire. In order to improve the transmission speed and stability of signals, high-speed signal processing technologies are usually used on PCB boards, such as differential signals, equalization processing, etc. In addition, in order to improve the anti-interference ability of the signal, shielding measures and decoupling technology will also be used.

Realization of electrical connection of electronic components

Electrical connection refers to the electrical signal connection between electronic components. On the PCB board, the electrical connections between electronic components are realized through conductive materials. Common conductive materials include copper, aluminum and other metal materials. Connection methods for conductive materials include welding, crimping, and plugging. Welding is the process of joining two conductors together through molten metal. It has the advantages of large contact area and reliable connection. Crimping is a process of connecting by compressing metal conductors. It has the advantages of small contact resistance and stable transmission performance. Plugging is the process of connecting by inserting plugs and sockets. It has the advantages of easy replacement and suitable for mass production.

Electronic component thermal design planning

Thermal design is one of the key factors to ensure the normal operation of electronic components on the PCB. Electronic components generate heat when working. If the heat cannot be effectively dissipated and controlled, it will cause the electronic components to overheat and damage or affect their performance. Therefore, during the PCB design stage, designers need to consider thermal design issues, including heat dissipation methods, selection of thermal conductive materials, and heat dissipation. Usually, heat dissipation measures such as radiators and fans are used on the PCB to ensure that the operating temperature of electronic components is within a safe range.

Electronic component processing and manufacturing technology

The manufacturing process of PCB boards mainly includes substrate production, circuit production, component installation, welding, testing and other links. During the production process, issues such as material selection, processing accuracy, and surface treatment need to be considered.

For example, in order to improve the mechanical strength and stability of PCB boards, polymer materials are usually used as substrates; in order to improve the conductivity and corrosion resistance of circuits, surface treatments such as copper plating and tin plating are required.

Electronic component adaptability and reliability testing

In order to ensure the working performance and stability of electronic components on the PCB, reliability testing is required. Reliability testing mainly includes environmental adaptability testing, life testing, reliability assessment and other links. Environmental adaptability testing mainly includes testing of environmental conditions such as temperature, humidity, salt spray, etc.; life testing mainly refers to accelerated aging tests of electronic components to evaluate their life and reliability; reliability evaluation mainly uses statistical methods to test the The data is processed and analyzed to assess the reliability level of the product.

In short, the work of electronic components on PCB boards involves many aspects such as circuit design, signal transmission, electrical connection, thermal design, manufacturing process and reliability testing.

In order to ensure the normal operation of electronic components, full consideration and optimization need to be carried out in the design stage, and quality and process flow must be strictly controlled during the manufacturing process. At the same time, reliability testing of the manufactured PCB boards is also a very important link to ensure that the quality and reliability level of the product meets the requirements.

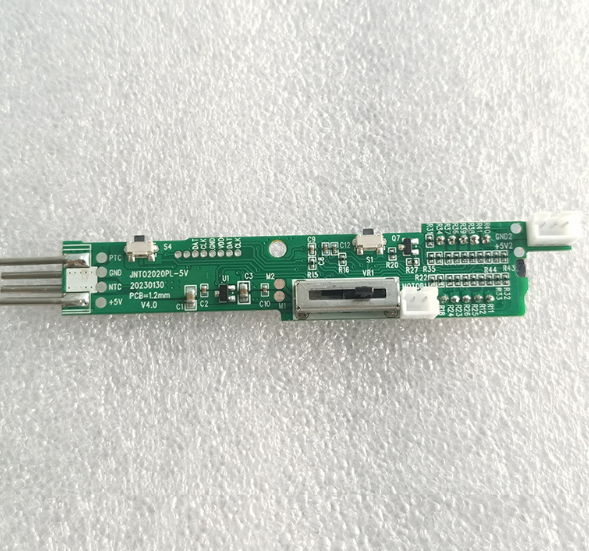

Electronic components on PCB board

The electronic components on the PCB mainly include the following:

- Resistor: used to limit current, divide voltage, eliminate interference, etc.

- Capacitor: used for charge storage, filtering, voltage stabilization, etc.

- Inductor: used to store magnetic fields, frequency division, filtering, etc.

- Diode: used for rectification, limiting, switching, etc.

- Transistor: used for amplification, switching, etc.

- Field effect transistor: used for amplification, switching, etc.

- Optocoupler: used for isolation, signal transmission, etc.

- Transistor: used for amplification, switching, etc.

- Integrated circuit: Integrate multiple electronic components together to achieve more complex circuit functions.

In addition, the PCB board may also include other components, such as power modules, sensors, motors, displays, and audio modules. The functions of these components are to provide power supply voltage and current, sense environmental information, drive mechanical movement, display images and text, and play sound and music.

How do the components of the circuit board work?

The components of the circuit board are designed and manufactured using electronic circuits, and their working principle can be understood as the following steps:

- Power supply: The components on the circuit board require power supply to work. The power supply transmits current through wires to various components on the circuit board, providing them with the required electrical energy.

- Signal transmission: Components on the circuit board receive and send signals through wires or other transmission media. These signals can be electrical signals, optical signals, magnetic signals, etc., used to control and transmit data, instructions and other information.

- Signal processing: The components on the circuit board process the received signals. For example, amplification, filtering, comparison, conversion, etc., to achieve specific functions or processing results.

- Output control: After signal processing, the components on the circuit board will control their output according to the processing results. This output can be an electrical signal, an optical signal, a mechanical signal, etc., used to drive other devices or implement specific functions.

The components of the circuit board work through steps such as power supply, signal transmission, signal processing and output control. These steps work together to enable the board to perform specific functions and tasks.

Top electronic components suppliers and manufacturers in China

E-components.globalbestshopping.com is a Chinese company focusing on the electronic components industry, with many years of industry experience and a professional technical team. The company mainly provides various types of electronic components, including integrated circuits, resistors, capacitors, diodes, etc. The products are widely used in communications, computers, consumer electronics and other fields.

We have established long-term and stable cooperative relationships with various brands of electronic component suppliers and well-known brand manufacturers around the world, and are known for providing high-quality, cost-effective products and services.

In addition, the supplier also provides customized services, providing customized electronic component solutions based on customer needs. The company’s business philosophy is customer-centered, quality as life, innovation as driving force, talent as fundamental, and is committed to providing customers with high-quality products and services.