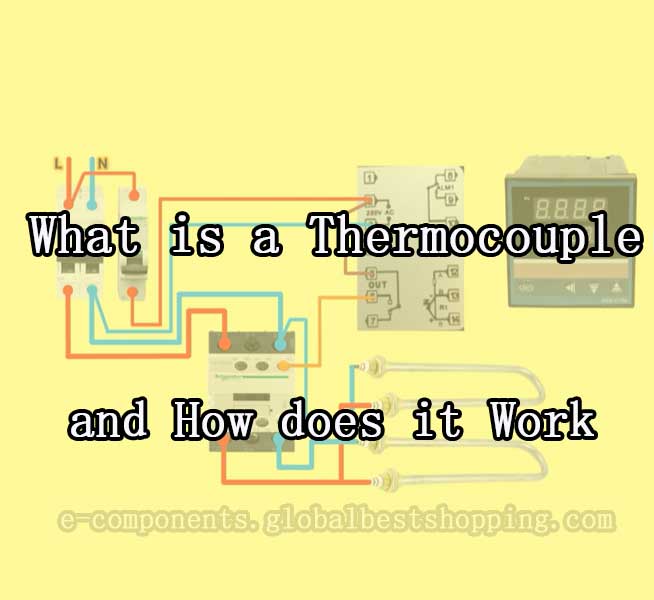

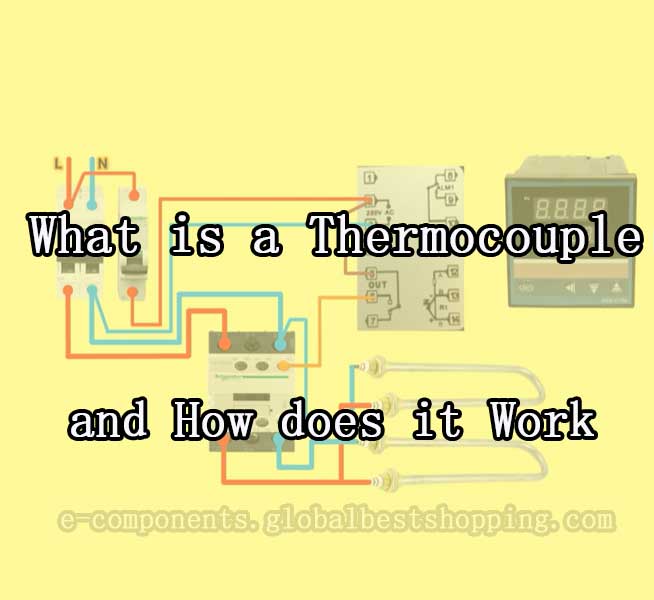

What is a Thermocouple and how does it work

A thermocouple is a temperature measuring element that can directly measure temperature and convert the temperature signal into a thermoelectromotive force signal, which is then converted into the temperature of the measured medium through an electrical instrument (secondary instrument).

The shapes of various thermocouples are often very different due to needs, but the basic structure is roughly the same. They usually consist of main parts such as hot electrodes, insulating sleeves, protective tubes, and junction boxes. They are usually matched with display instruments, recording instruments, and electronic regulators. use.

Are thermocouples electronic components?

Thermocouples are electronic components. It is composed of two probes made of different metals or alloys. When the two ends of the probe come into contact with objects with different temperatures, an electromotive force is generated.

The magnitude of the electromotive force is proportional to the temperature difference of the probe. Therefore, thermocouples can be used to measure temperature.

Are thermocouples electronic components or electronic devices?

Thermocouples are both electronic components and electronic devices.

From the perspective of electronic components, a thermocouple is composed of two probes made of different metals or alloys. When the two ends of the probes come into contact with objects with different temperatures, an electromotive force is generated. The magnitude of the electromotive force is proportional to the temperature difference of the probe. Therefore, thermocouples can be used to measure temperature.

From an electronics perspective, thermocouples often form temperature detectors along with other circuit components. The temperature detector can convert the electromotive force generated by the thermocouple into a digital signal and output the digital signal to the control circuit. Control circuits can control the operation of equipment based on digital signals.

Therefore, thermocouples are electronic components that can be used alone or together with other circuit components to form electronic devices.

Thermocouple is a very important electronic component with a wide range of applications.

How do thermocouples work?

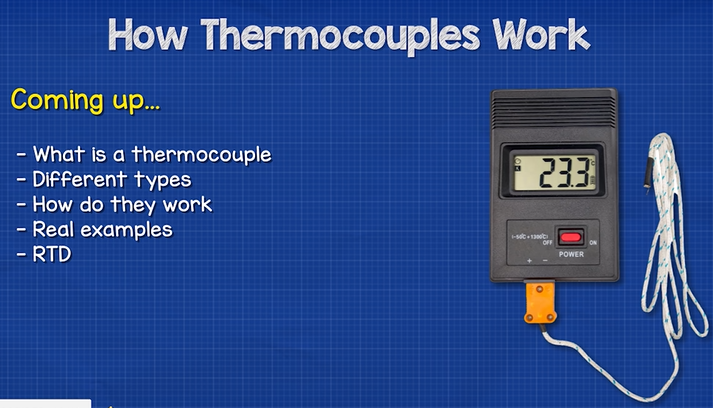

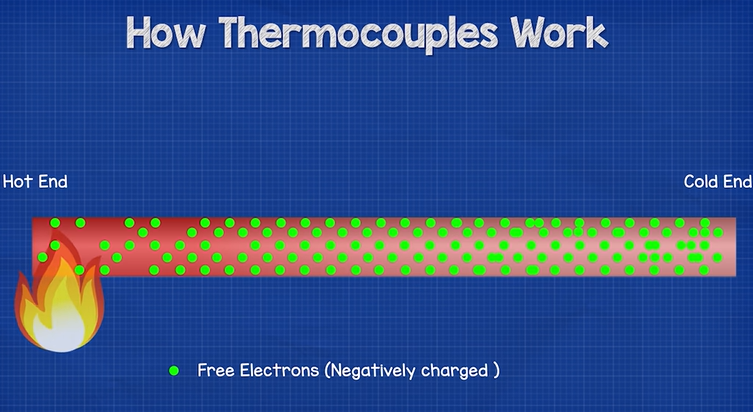

The working principle of thermocouples is the thermoelectric effect. Specifically, two wires of different metals are connected to form a circuit, one of the contacts is heated, and the other contact is in an unheated (cold spot) state.

Due to the different electron concentrations and movement speeds in different metals, a The phenomenon of electron diffusion forms a current in a closed circuit, producing a wide temperature difference electromotive force.

This electromotive force is called thermoelectric potential. By measuring the magnitude of the thermoelectric potential, the temperature of the measured point can be known.

What are the disadvantages of thermocouples?

As a common temperature sensor, thermocouples have many advantages, such as wide temperature measurement range, stable performance, high measurement accuracy, fast thermal response time, high mechanical strength, high temperature resistance, long service life, etc. However, it also has some disadvantages, including:

- Low accuracy: The accuracy of thermocouples is usually affected by a variety of factors, such as internal inherent inaccuracies caused by metal properties, errors in the signal scheduling process, etc., resulting in low accuracy.

- Susceptible to corrosion: Since the thermocouple is composed of two different metals, corrosion over time may affect accuracy under some working conditions. Therefore, they may require protection, and maintenance and protection is essential.

- Poor noise immunity: Noise generated by stray electric and magnetic fields can cause problems when measuring millivolt-level signal changes. Twisted thermocouple wire pairs may significantly reduce magnetic field coupling. Electric field coupling can be reduced by using shielded cables or routing and shielding within metal conduits. The measurement component should provide signal filtering in the form of hardware or software to effectively suppress power frequency (50 Hz/60 Hz) and its harmonics.

Despite these shortcomings, thermocouples are still widely used in many fields.

What are the application areas of thermocouples?

The application fields of thermocouples are very wide, including but not limited to the following aspects:

Power metallurgy

Used to measure and control temperature parameters in various production processes, such as heating processes, smelting processes, etc.

Petrochemical industry

In the petrochemical industry, thermocouples are used to measure and control the temperature of various chemical reactions to ensure the stability and safety of the production process.

Food processing

During food processing, thermocouples can be used to measure and control the temperature of food processing equipment to ensure food hygiene and quality.

Water treatment

During the water treatment process, thermocouples can be used to measure and control the temperature of water treatment equipment to ensure the efficiency and effectiveness of water treatment.

Thermocouple is a temperature measurement element widely used in various industrial fields and plays an important role in ensuring the stability and safety of the production process.

What are the characteristics and uses of Thermocouples?

Thermocouple temperature measuring elements have the following characteristics and uses:

High measurement accuracy

Thermocouples have high measurement accuracy and can meet the temperature measurement needs in various industrial production processes.

Wide measurement range

Thermocouples have a wide measurement range, ranging from low temperature to high temperature, and are suitable for various industrial fields.

Fast response speed

The thermocouple has a fast response speed and can quickly respond to temperature changes and transmit temperature data in a timely manner.

Simple structure

The thermocouple has a simple structure, is easy to install and maintain, and can adapt to various harsh environments.

Strong corrosion resistance

Thermocouples have strong corrosion resistance and can adapt to various chemical substances and high temperature environments to ensure measurement accuracy and stability.

Affordable price

Thermocouples are affordable, cost-effective, and suitable for large-scale applications.

In the field of industrial automation, thermocouples are mainly used for temperature measurement and control.

It can be installed on various industrial equipment, such as boilers, steam turbines, reactors, etc., to monitor the operating temperature of the equipment in real time and transmit the data to the control system to help operators adjust operating parameters in a timely manner to ensure normal operation of the equipment.

At the same time, thermocouples can also be used for temperature compensation and parameter adjustment of control systems to improve production efficiency and product quality.

What role do thermocouples play in industrial automation?

In the field of industrial automation, the main role of thermocouples is to measure and control temperature.

A thermocouple is a sensor that directly measures temperature. It can convert the temperature into an electrical signal, and then convert it into the temperature of the measured medium through an electrical instrument (secondary instrument). Therefore, thermocouples are key components for automatic temperature control.

In many industrial production processes, such as steel smelting, chemical reactions, glass manufacturing, etc., precise temperature control is required. In these cases, thermocouples can measure temperature in real time and transmit the data to the control system to help operators adjust operating parameters in a timely manner to ensure normal operation of equipment and improve production efficiency and product quality.

At the same time, thermocouples are also widely used in the power industry. In the power industry, the operating temperature of boilers, turbines and other equipment is critical to power production. Thermocouples can monitor the operating temperature of the equipment in real time and transmit the data to the control system to help operators adjust operating parameters in a timely manner to ensure normal operation of the equipment.

In addition, thermocouples also have the advantages of simple structure, easy use, and stable performance, so they have been widely used in the field of industrial automation.

Thermocouple Example

How does a thermocouple work on a gas valve

The basic principle of thermocouples working on gas valves is to utilize the thermoelectric effect. The thermoelectric effect refers to the phenomenon that an electromotive force is generated when the electrodes of two different conductors or semiconductors come into contact with objects of different temperatures.

On gas valves, thermocouples are usually used to detect the temperature of gas after combustion. The two probes of the thermocouple are in contact with the air after gas combustion and the external air respectively. When the gas is burned, the temperature of the air will increase. Because the two probes of the thermocouple have different temperatures, an electromotive force is generated. The magnitude of the electromotive force is proportional to the temperature difference between the two probes.

The control circuit of the gas valve controls the flow of gas based on the electromotive force generated by the thermocouple. When the air temperature after gas combustion reaches a certain value, the control circuit will cut off the flow of gas. This can prevent excessive combustion of gas and cause safety accidents.

Specifically, the working process of thermocouples on gas valves is as follows:

- Contact the two probes of the thermocouple with the air after gas combustion and the external air respectively.

- When gas is burned, the temperature of the air will increase.

- Since the two probes of the thermocouple have different temperatures, an electromotive force will be generated.

- The magnitude of the electromotive force is proportional to the temperature difference between the two probes.

- The control circuit of the gas valve will control the flow of gas based on the electromotive force generated by the thermocouple.

A thermocouple is a very effective gas valve temperature detector. It has the following advantages:

- High precision. The measurement accuracy of thermocouples can reach ±0.1°C.

- Good stability. The measurement stability of the thermocouple can reach ±0.01℃.

- Good durability. The service life of thermocouples can reach more than 50,000 hours.

Therefore, thermocouples are widely used in gas valves.