The 2024 China Integrated Circuit Design Innovation Conference will be held at the Wuxi International Convention Center from September 25th to 27th.

The conference focuses on the latest technology, market trends and industry dynamics of integrated circuit design, aiming to promote collaborative innovation and cross-border integration of the industry chain and help the vigorous development of my country’s integrated circuit industry.

Major research institutions believe that after the global semiconductor market reaches a cyclical low in 2023, there will be an overall recovery trend this year.

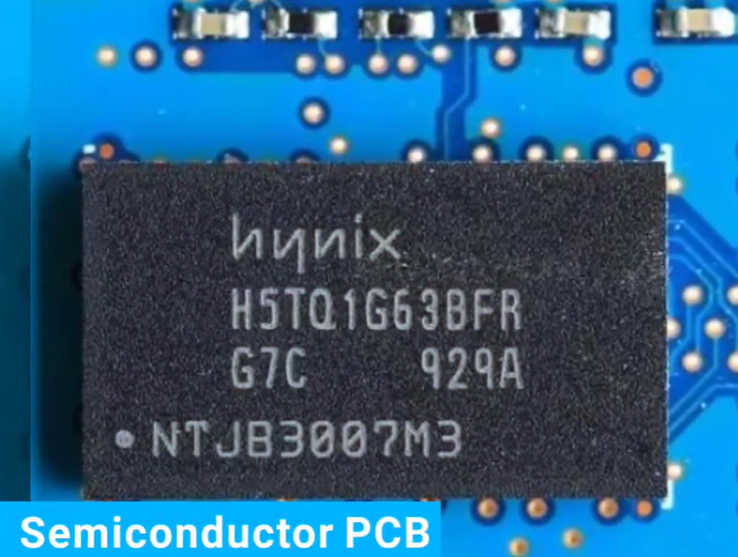

Gartner predicts that global semiconductor industry revenue will reach US$624 billion in 2024, a year-on-year increase of 16.8%. The storage industry, known as the “barometer” of the semiconductor industry, was the first to experience price increases in the fourth quarter of last year, which has continued into this year and is expected to rebound by 66.3%.

The driving force behind this is the new wave of AI detonated by generative artificial intelligence (AIGC) led by ChatGPT. High-tech companies in data centers, servers, cloud computing, large computing power chips, large models and other fields quickly followed up, forming a new global AI arms race, which directly drove the development of high-bandwidth memory (HBM), GPU and other AI computing power-related technologies. Chip growth.

As consumer electronics such as PCs, mobile phones, and tablets continue to recover, the first year of AI PC begins, and the “new four modernizations” of automobiles enter the deep water area, what new changes will occur in the chip industry this year? How to seize the opportunity for recovery? How about upstream and downstream Form a better coordination mechanism?

The 2024 China Integrated Circuit Design Innovation Conference and the 4th IC Application Expo (ICDIA 2024) will be held at the Wuxi International Convention Center from September 25-27. As the top event in China’s IC design industry and electronic technology industry, ICDIA is committed to promoting the application of chips, IC components and systems, and demonstrating China’s core innovation achievements and technological progress.

ICDIA 2024 will focus on the outstanding Chinese chip and innovative applications and achievements, bring eye-catching cutting-edge innovation results to the audience, and display the chip picture of future technology.

With the theme of “Application Innovation, Creating a New Ecosystem”, this conference focuses on the two main lines of “chip industry ecology” and “application-enabled industry upgrading”, with six theme forums, multiple innovation releases and application docking, IC application Exhibition, market-oriented and product-centered to build a supply and demand communication platform for chip applications.

It is worth noting that four large-scale exhibitions on integrated circuit design, packaging and testing, equipment and components, and automotive electronics are gathered at the same time, with a total exhibition area of nearly 50,000 square meters and more than 100,000 professional visitors. It is the largest exhibition for global IC companies and electronic R&D It is the best platform for enterprises to display innovative technologies, explore business opportunities and promote trade cooperation.

Paying attention to innovative applications, promoting application implementation, building a supply and demand platform, and assisting the construction of the chip industry ecosystem are the original intention of ICDIA’s establishment and the characteristics of ICDIA.

Six major theme forums

Create a feast of cutting-edge technology

This conference features six major theme forums, including “Large Models and AI Large Computing Power Chips”, “Low Power Consumption and Embedded Design“, “RSIC-V and IP Applications”, “Chip Cloud and Data Security”, “Communications and Radio Frequency Technology”, “Innovation Release and Application Docking”.

“Low Power Consumption and Embedded Design” Forum

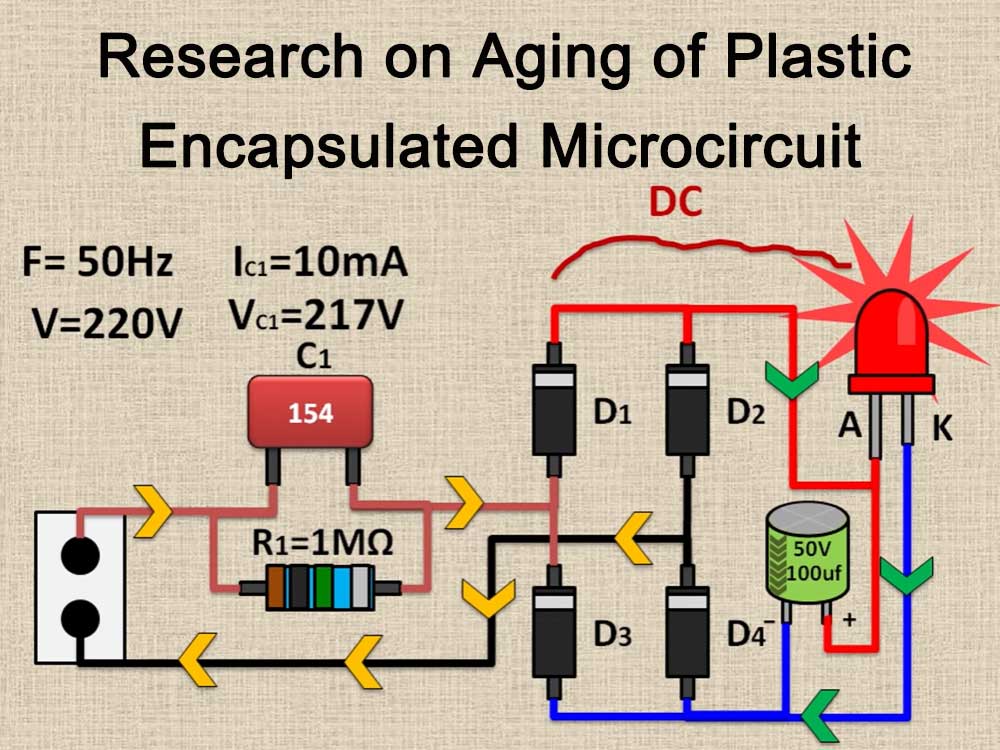

With the continuous deepening of urban informatization and industry intelligence, embedded technology has become one of the fastest growing and most widely used computer technologies in the information industry, and is widely used in consumer electronics, medical electronics, industrial control, and intelligent hardware. In other fields, data from the Ministry of Industry and Information Technology shows that my country’s embedded system software market size will reach 937.6 billion yuan in 2022, a year-on-year increase of 11.04%; it is expected that the embedded system software market size will exceed 1 trillion yuan in 2023.

As digital transformation penetrates into all walks of life and the development of artificial intelligence applications is promoted, low power consumption and high performance will become the core direction of the future development of embedded technology.

This “High Performance Low Power Consumption and Embedded Design” forum will focus on the development and innovative application results of embedded technology in the fields of artificial intelligence, smart terminals, Internet of Things, edge computing, industrial control, etc., and promote the ecological construction of software and hardware systems. Strengthen upstream and downstream communication and collaboration to jointly discuss the future development of embedded systems.

“Large Models and AI Big Computing Power Chips” Forum

The explosion of ChatGPT triggered a wave of generative artificial intelligence. Almost at the same time, major Internet high-tech companies were competing to deploy large-scale artificial intelligence model applications and promote the deeper development of artificial intelligence in various fields. In the future, artificial intelligence may change people’s lives. daily life.

With the advent of the era of large artificial intelligence models, the massive demand for computing power has led to arms races one after another in the fields of data centers, servers, and large computing power chips. Data shows that the global AI accelerated computing market will reach US$45 billion in 2023, and is expected to reach US$400 billion by 2027.

This “Large Models and AI Large Computing Power Chips” forum will focus on the development of various large models and the latest application results, AI large computing power chips, including but not limited to GPU, ASIC, CPU, FPGA, GPGPU, etc., aiming to explore The integrated development of large model applications and computing power chips, explores the requirements of different artificial intelligence applications for computing power chips, and the technological development of computing power chips in the post-Moore era including storage and calculation integration and other types of computing structures.

“Cloud on Chip and Data Security” Forum

In the past, most chip design companies focused on local computing power. However, driven by new generation information technologies such as artificial intelligence, 5G, supercomputing, and autonomous driving, chip design is becoming more and more complex, and manufacturing processes are becoming more and more advanced. , the cost has also increased, bringing considerable pressure and challenges to chip design and development.

The use of cloud computing is currently a way to solve the computing power gap faced by chip design and help small and medium-sized enterprises balance costs. Therefore, “chip on the cloud” is becoming a major trend in the chip design industry.

How to get to the cloud? What are the options? How to ensure costs? How to support the “elastic computing power” of chip design? How to ensure security in the semiconductor industry that is extremely sensitive to data?

This “Chip Cloud and Data Security” forum will discuss the above issues, focusing on the situation, difficulties and data security issues of the chip industry’s cloud migration, aiming to establish a communication bridge between the chip industry and cloud service providers, and help build a domestic cloud service ecosystem. Help chip companies find good solutions and make good use of cloud computing to conduct business.

“RISC-V and IP Application” Forum

Since the development of the open source reduced instruction set architecture RISC-V, more and more companies, schools, and scientific research institutes have joined in. RISC-V is more flexible than traditional instruction set architecture, compatible with a wide range of applications, and is mostly used in the field of intelligent Internet of Things. Today, many companies around the world are expanding the RISC-V ecosystem and core applications, covering image sensors, security management, artificial intelligence computing, etc.

Data shows that RISC-V revenue will reach US$800 million in 2023, nearly double the previous two years, and is expected to reach nearly US$1 billion in 2024. As more and more companies embrace the RISC-V ecosystem, they may be able to compete with ARM and x86 in the future.

The open source and open nature of RISC-V will help China break through Western restrictions and achieve independent control. But it is undeniable that RISC-V is still relatively new. Compared with the complete and mature ecology of ARM and x86, it also faces problems such as ecological fragmentation, lack of some features, and insufficient high-end application market.

This “RISC-V and IP Application” forum mainly focuses on the sharing of innovative results and cutting-edge technologies in RISC-V technology, ecological application construction, IP cores and development tools, etc., and discusses the difficulties and difficulties in building a RISC-V open source and open ecosystem. Challenges, current status and future development trends of domestic IP applications.

“Communications and Radio Frequency Technology” Forum

In recent years, as the penetration rate of 5G continues to increase, the value and importance of radio frequency front-end chips have become increasingly prominent in mobile terminals. The domestic RF front-end industry has developed vigorously under the wave of domestic substitution and the rise of domestic terminals.

Data shows that after years of development, many outstanding companies have emerged in my country in the fields of switches, PA, WIFI FEM, filters and other subdivisions, and the global market share of RF front-end companies has reached more than 10%.

From a global perspective, the top five leading RF front-end companies have a combined market share of up to 80%, and there is still a lot of room for domestic substitution. Although there are many domestic start-ups pouring into the radio frequency track, there are still “partiality” situations.

For example, filter products are mostly concentrated in the mid- to low-end, and there is a lack of high-end products.

The materials, processes and packaging and testing technologies involved in RF front-end chips are not simple. How to achieve high-end breakthroughs in specific fields is still a big test for domestic RF companies.

With the technological advancement of 6G and WIFI7, as well as the popularization and promotion of UWB (ultra-wide) applications, future communication technology innovations will also bring new applications and new needs.

This “Communications and Radio Frequency Technology” forum mainly focuses on cutting-edge communications and radio frequency technologies, discusses the opportunities and challenges that emerging communications technologies bring to radio frequency technology, as well as the development of my country’s radio frequency front-end chip and module industry, and shares the latest application results. Promote my country’s radio frequency industry to advance into high-end fields.

“Innovation Release and Application Docking” Forum

China has become the world’s largest electronic application market, with chip demand ranking first in the world. In order to accelerate the docking and promotion of upstream and downstream applications, ICDIA will select 30 chips with the most market potential based on more than 1,000 domestic chip companies collected in the “China Chip Product Catalog” (formerly China Chip Compilation) and organize roadshow releases and application docking , assisting upstream and downstream collaboration.

Chip innovation supports and leads technological innovation. “Innovation Release and Application Docking” will invite major electronic equipment companies, R&D institutions, and system manufacturers to participate. It will also invite experts, scholars, business representatives, etc. to provide suggestions for accelerating the development of the domestic chip industry.

Four major exhibitions gathered at the same time

IC Application Expo “New”

In addition to the ICDIA Summit Forum and thematic forums, the IC Application Exhibition, the 11th Automotive Electronics Innovation Conference and Exhibition (AEIF), the 5th Automotive Chip Supply and Demand Matchmaking Conference, and the 12th Semiconductor Equipment Annual Conference and Semiconductor Equipment were held concurrently. The display of core components (CSEAC 2024) is also exciting.

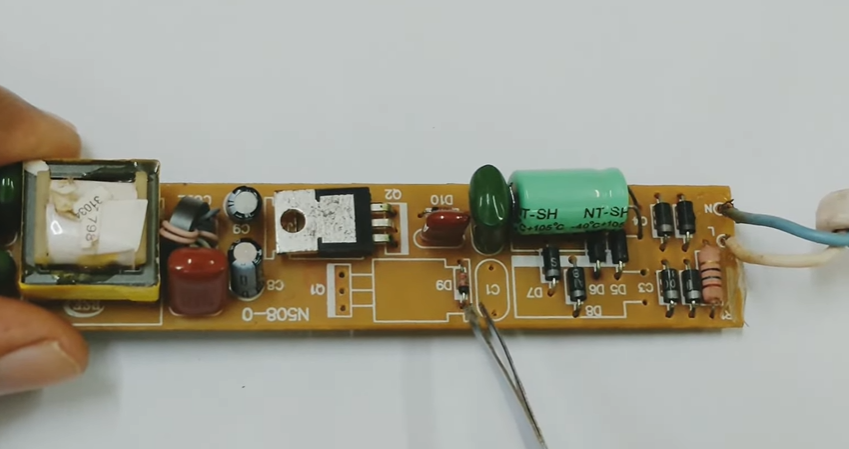

IC Application Exhibition (IC Expo)

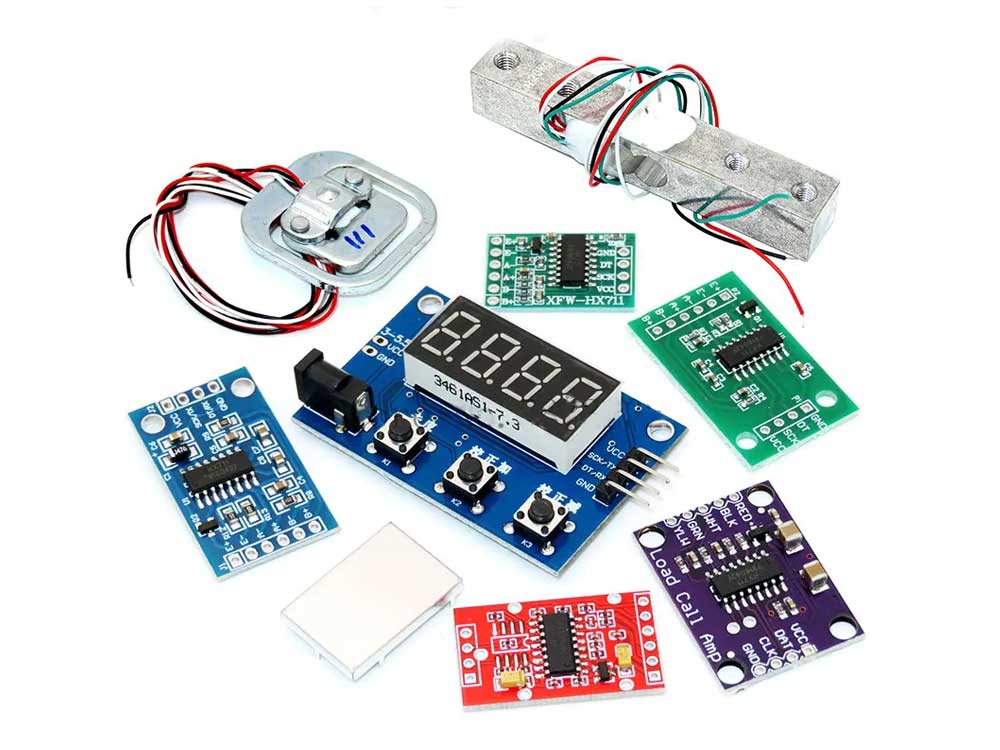

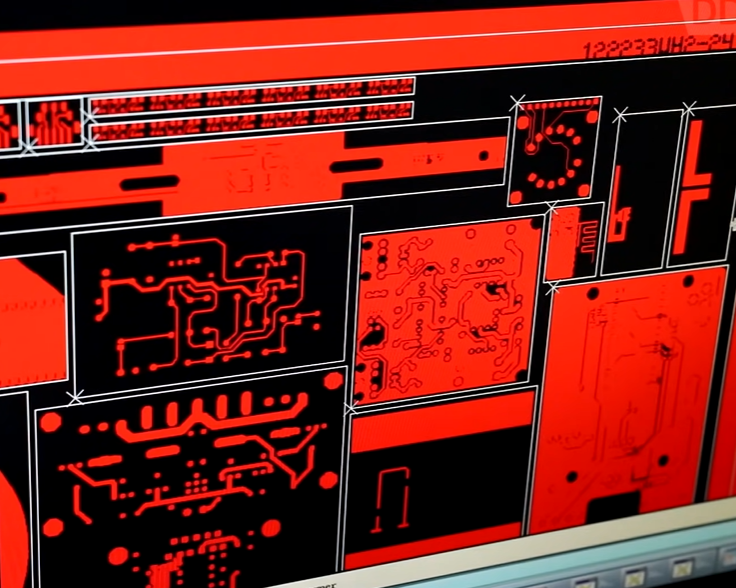

IC Expo is the first professional boutique exhibition dedicated to chip innovation, software, system solutions and product applications. The exhibition is divided into three major exhibition areas: [Innovative Chinese Chip], [Automotive Electronics], and [Black Technology Application], focusing on IC design technology, artificial intelligence, intelligent terminals, Internet of Things, smart transportation, in-vehicle entertainment, health technology, sports technology, and smart technology. New products, new technologies, new scenarios, and new applications such as home furnishings.

AEIF 2024

This year’s 11th AEIF will focus on the innovative development of the domestic and foreign automotive semiconductor industry and explore automotive electronics technology paths and market trends. The forum held at the same time focused on topics such as the development of intelligent connected vehicles, automotive chip system design innovation, and new energy vehicle innovation. The “Domestic Automotive Chip Reliability Grading Catalog (2024)” will also be released at the meeting, and there will also be an automotive chip supply and demand matchmaking meeting Promote the docking of automotive chip production and research, production and demand, and industry and finance.

From September 25th to 27th, 2024, we will gather in Wuxi to discuss the chip industry ecology and application development. We look forward to your arrival!

About ICDIA

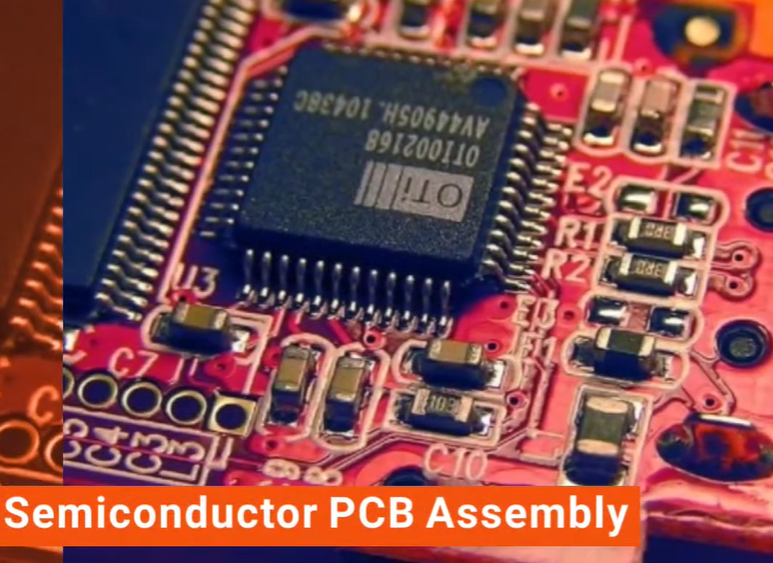

The China Integrated Circuit Design Innovation Conference (ICDIA) focuses on the ecological construction of the IC industry chain and is committed to promoting the application of chips in automobiles, communications, and consumer electronics. It is China’s first boutique exhibition focusing on IC design innovation and system applications.

Previous conferences have focused on displaying new products, new technologies, and new applications, focusing on promoting innovative IC products and application solutions in the fields of automotive electronics, artificial intelligence, consumer electronics, industrial control, communications, and the Internet of Things.

The conference includes 1 thousand-person summit forum, 6 theme forums, and 1 IC application exhibition, displaying the TOP 100 best Chinese chips and innovative black technologies, and promoting new products, new technologies, and new applications.

IC design companies from across the country, supply chain procurement centers of various brands of electronic manufacturers, and R&D teams of major technology companies gathered together to share chip innovation results and future applications, and to take the pulse of new trends, trends, and trends in electronic technology.