Parallel capacitors are usually made of aluminum metal film, polypropylene film, epoxy resin and other materials.

Below is a detailed introduction to these materials:

aluminum metal film

Aluminum metal film is one of the most common capacitor electrode materials and has good electrical conductivity and corrosion resistance. During the capacitor manufacturing process, an aluminum metal film is usually deposited on a polypropylene film by evaporation or sputtering to form a metal film.

The thickness of aluminum metal film is generally between 100-300 nanometers. It has good self-healing ability and high dielectric constant, making the capacitor have high capacitance.

Electrode material is another core component of the capacitor, which determines the conductive properties of the capacitor.

Commonly used electrode materials include aluminum foil, tantalum, silver, gold, etc. Aluminum foil is the most commonly used electrode material because of its good conductivity and cost-effectiveness. Tantalum and silver also conduct electricity well, but they cost more. Gold conducts electricity very well, but it’s also very expensive.

For electrode materials, commonly used electrode materials include:

Aluminum

Aluminum has good electrical conductivity and corrosion resistance, and is a commonly used material for making capacitors.

Silver

Silver has good electrical conductivity and high temperature resistance, and is a commonly used material for making high-frequency capacitors.

Gold

Gold has good electrical conductivity and oxidation resistance, and is another commonly used material for making high-frequency capacitors.

polypropylene film

Polypropylene film is another common capacitor insulating material with good electrical properties, mechanical properties and chemical stability.

In the manufacturing process of capacitors, polypropylene films are usually made by biaxial stretching and have the characteristics of high crystallinity, high mechanical strength, and excellent electrical properties. The thickness of polypropylene film is generally between 2-10 microns and has a low dielectric constant, allowing the capacitor to have low dielectric loss and heat loss.

Epoxy resin

Epoxy resin is a common organic polymer material with good insulation properties, adhesion properties and temperature resistance.

In the capacitor manufacturing process, epoxy resin is often used as an impregnating agent and sealing material, which can effectively protect the internal components of the capacitor and increase the mechanical strength of the capacitor.

At the same time, epoxy resin can also improve the insulation performance and temperature resistance of capacitors, allowing capacitors to operate at higher temperatures and voltages.

In addition to the above main materials, parallel capacitors also require other auxiliary materials, such as pins, insulators, casings, etc. The selection and use of these auxiliary materials also affects the performance and reliability of the capacitor.

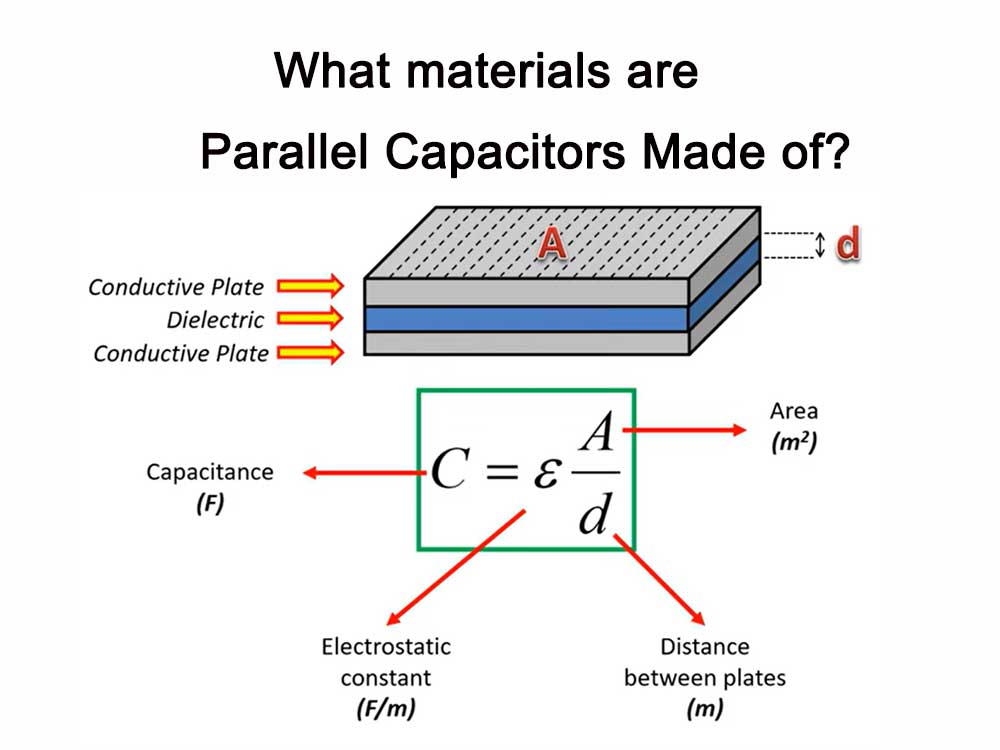

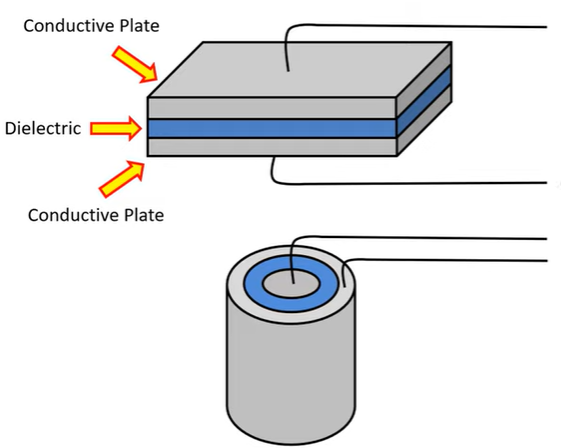

Dielectric material

The dielectric material is the core component of the capacitor, which determines the capacitance of the capacitor.

Commonly used media materials include:

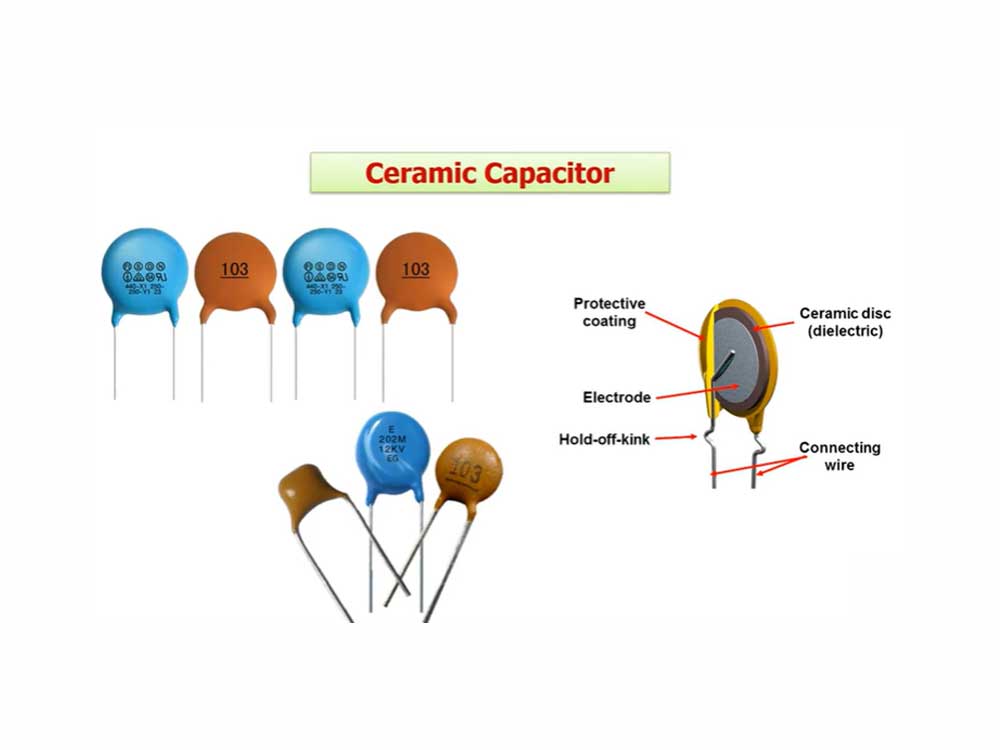

Ceramic materials

Ceramic materials have good electrical insulation properties and stability and are commonly used materials for making capacitors.

Plastic material

Plastic material has good electrical insulation properties and corrosion resistance, and is another commonly used material for making capacitors. Commonly used plastic materials include polyethylene, polypropylene, polytetrafluoroethylene, etc.

Paper capacitor

Paper capacitor has good electrical insulation properties and high voltage resistance, and is a commonly used material for making high-voltage capacitors.

The material selection of parallel capacitors needs to be based on the specific application of the capacitor. For example, for capacitors that require high capacitance and stability, ceramic or plastic dielectrics can be used, and electrode materials such as aluminum or silver can be used.

For capacitors that require high-frequency characteristics, paper capacitors can be selected and electrode materials such as gold or silver can be used.

The material selection and use of a shunt capacitor has a significant impact on its performance and reliability. In practical applications, appropriate materials and manufacturing processes need to be selected according to specific requirements to ensure optimal performance and reliability of shunt capacitors.