Research electronic component chip materials

In this article, we will explain the research on electronic component chip materials, including electronic component chip materials, composition, application fields and development trends.

Studying electronic component chip materials is of great significance to promoting the development of modern electronic technology and involves many key fields.

These materials are critical to improving chip performance, stability and reliability and are critical to meeting growing technology demands.

What material are electronic component chips made of?

The material of electronic component chips is mainly silicon, which is a semiconductor material. Silicon is refined from quartz sand, with a purity requirement of 99.999%.

Specifically, the chip manufacturing process is as follows: first, pure silicon is made into silicon ingots, and then sliced into slices. This is the wafer required for chip manufacturing. The thinner the wafer, the lower the production cost, but the higher the process requirements.

Electronic component chips are mainly composed of the following materials:

Semiconductor material

Semiconductor materials are the core materials of electronic component chips, which determine the performance and functions of the chip. Commonly used semiconductor materials include silicon, germanium, gallium arsenide, etc. Semiconductor materials have electrical conductivity between conductors and insulators, and their electrical conductivity can be changed through doping and other means to achieve control of electrical signals.

Commonly used semiconductor materials include:

Silicon: Silicon is the most commonly used material for electronic component chips, accounting for approximately 80% of the global semiconductor market. Silicon is a chemical element with the symbol Si and atomic number 14. Silicon is a non-metal with semiconductor properties.

Germanium: Germanium is a chemical element with the symbol Ge and atomic number 32. Germanium is a metal with semiconductor properties. Germanium is more conductive than silicon but is also more expensive.

Gallium Arsenide: Gallium arsenide is a chemical compound with the formula GaAs. Gallium arsenide is a direct band gap semiconductor with high frequency, high power and high efficiency characteristics. Gallium arsenide is widely used in optoelectronic devices, radio frequency devices and power devices.

metallic material

Metal materials are used for chip connection, packaging, etc. Metal materials have good electrical and thermal conductivity and can provide good connection and heat dissipation properties for the chip. Commonly used metal materials include copper, aluminum, silver, etc.

Commonly used metal materials include:

Copper: Copper is a chemical element with the symbol Cu and atomic number 29. Copper is a metal that has good electrical and thermal conductivity.

Aluminum: Aluminum is a chemical element with the symbol Al and atomic number 13. Aluminum is a metal that has good electrical and thermal conductivity, but has a low density.

Silver: Silver is a chemical element with the symbol Ag and atomic number 47. Silver is a metal that has good electrical and thermal conductivity, but is more expensive.

plastic material

Plastic materials are used for packaging of chips. Plastic materials have good insulation and corrosion resistance, which can protect the chip from damage from the external environment. Commonly used plastic materials include epoxy resin, polyimide, etc.

Commonly used plastic materials include:

Epoxy resin: Epoxy resin is a chemically synthesized material with good insulation and corrosion resistance.

Polyimide: Polyimide is a chemically synthesized material with good insulation, heat resistance and chemical resistance.

Ceramic material

Ceramic materials are used for chip packaging. Ceramic materials have good insulation, heat resistance and chemical resistance, which can protect the chip from damage by high temperatures and corrosive media. Commonly used ceramic materials include alumina, silicon nitride, etc.

Commonly used ceramic materials include:

Alumina: Aluminum oxide is a chemical compound with the formula Al2O3. Aluminum oxide is a ceramic material that has good insulation, heat resistance and chemical resistance.

Silicon Nitride: Silicon nitride is a chemical compound with the formula Si3N4. Silicon nitride is a ceramic material with good insulation, heat resistance and corrosion resistance.

Research electronic component chip materials examples

One of the research examples of electronic component chip materials is the application of silicon carbide (SiC) materials in electronic chips. Silicon carbide is a material whose hardness is second only to diamond. It has high thermal conductivity and high electron saturation mobility, so it is widely used in manufacturing high-power, high-frequency electronic component chips.

In electronic chip manufacturing, silicon carbide materials can be used to manufacture high-voltage, low-loss, high-frequency power devices, such as MOSFETs, IGBTs, etc. Compared with traditional silicon power devices, silicon carbide power devices have the advantages of higher operating frequency, higher efficiency, lower loss and higher voltage withstand capability. Therefore, they are widely used in fields such as electric vehicles, wind power, and rail transit. It has broad application prospects.

In addition, silicon carbide materials can also be used to manufacture high-frequency electronic component chips such as radio frequency devices and microwave devices. Due to silicon carbide’s high electron saturation mobility and hardness, its radio frequency and microwave devices have the advantages of high efficiency, high power density and low noise, so it has broad application prospects in communications, radar, electronic warfare and other fields.

In short, one of the research examples of electronic component chip materials is the application of silicon carbide materials in electronic chips. Through continuous research and exploration, more advanced, efficient, and environmentally friendly electronic component chip materials can be developed, providing more possibilities for the future electronics industry.

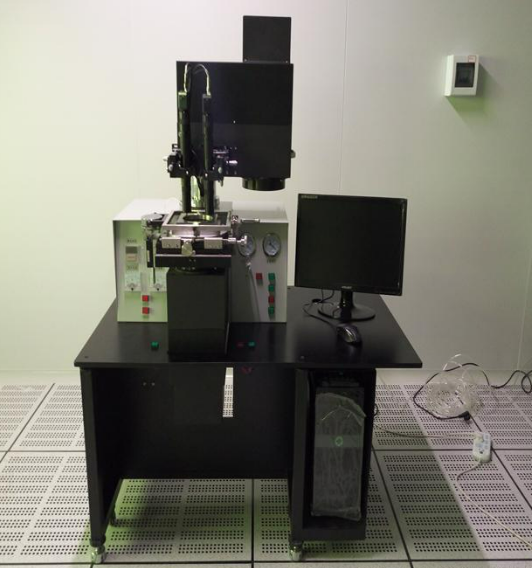

What equipment is used to make chips?

There are many types of equipment for manufacturing chips. Here are some of the main ones:

Lithography

The photolithography machine is one of the most critical equipment for manufacturing chips. It can transfer designed patterns to silicon wafers through photolithography technology.

Thin film deposition equipment

Thin film deposition equipment is used to deposit various metals, oxides, nitrides and other substances on silicon wafers to form circuit structures.

Plasma etching equipment

Plasma etching equipment can etch areas of the chip that are not covered by the thin film layer to form circuit structures.

Chemical mechanical grinding equipment

Chemical mechanical polishing equipment is used to grind uneven areas on the chip surface to form a smooth surface.

Single crystal furnace

The single crystal furnace is used to melt polycrystalline materials such as polycrystalline silicon with a graphite heater in an inert gas environment, and grow single crystals without dislocation using the Czochralski method.

Wafer dicing machine

Wafer dicing machines are used to cut wafers into small pieces.

Wafer thinning machine

The wafer thinning machine is used to remove a certain thickness of excess matrix material on the back of the wafer.

Vapor phase epitaxy furnace

The vapor phase epitaxial furnace is used to grow single crystal thin layers and is a single crystal thin layer growth method.

The above are only some of the equipment used to manufacture chips. The entire manufacturing process requires the use of many other equipment and process technologies.

Research electronic component chip materials

The research on electronic component chip materials is a very important field and involves many aspects. The following are some research contents on chip materials for electronic components:

Material selection

The selection of electronic component chip materials directly affects the performance and reliability of the chip. Different materials have different electronic transmission properties, device efficiency, thermal stability and other characteristics. Therefore, appropriate materials need to be selected based on specific application needs and process requirements.

Manufacturing process

The manufacturing process of electronic component chips involves multiple links, such as film deposition, photolithography, etching, testing, etc. These process parameters and technology choices will directly affect the size, shape and quality of the device. Therefore, in-depth research on manufacturing processes is needed to improve manufacturing efficiency and yield.

Reliability study

Electronic component chips may be subject to various stresses during use, such as temperature changes, mechanical stress, etc. These stresses may cause device performance degradation or failure. Therefore, it is necessary to conduct in-depth research on the reliability of electronic component chips, including life prediction, failure analysis, etc.

Research on new materials

With the continuous advancement of science and technology, new electronic component chip materials are constantly emerging. These new materials have higher performance and better reliability to meet the needs of more demanding applications. Therefore, in-depth research on new materials is needed to explore their properties and application potential.

Environmental protection and sustainable development

With the improvement of environmental awareness, the environmental protection and sustainable development of electronic component chips have attracted more and more attention. Therefore, it is necessary to study the environmental performance of electronic component chips, including material recyclability and environmental impact during the production process.

In short, the research on chip materials for electronic components is an evolving field that requires continuous in-depth research and technological innovation to meet growing application demands and improve device performance and reliability.

What are the important areas of research on chip materials for electronic components?

Research on electronic component chip materials involves many important fields. The following are some of the main fields:

Nanotechnology

With the development of chip manufacturing technology, nanotechnology plays an important role in chip material research. Through nanotechnology, smaller and faster chips can be manufactured, improving chip performance and efficiency.

Silicon material

Silicon is the main material for manufacturing chips and has the characteristics of high purity, high stability, and high heat resistance. Research on silicon materials mainly focuses on improving purity, improving crystal structure, reducing defects, etc., to improve chip performance and stability.

Compound semiconductor materials

Compound semiconductor materials such as gallium arsenide and gallium nitride have excellent optical, electrical and mechanical properties and are important materials for manufacturing high-efficiency and high-reliability chips. Research on these materials mainly focuses on improving their performance, stability and reliability.

Two-dimensional materials

Two-dimensional materials such as graphene and two-dimensional semiconductors have unique electrical, optical and mechanical properties and are important candidates for manufacturing next-generation chips. Research on these materials mainly focuses on preparation, performance control, and device applications.

Optoelectronic materials

With the development of optical communication and optical computing technology, optoelectronic materials play an increasingly important role in chip manufacturing. Research on optoelectronic materials mainly focuses on improving their luminous efficiency, light absorption and light transmission properties.

Biochip materials

Biochips are important tools for biological detection and analysis, and their manufacture involves the interaction of multiple biomolecules and biological cells. Research on biochip materials mainly focuses on improving their biocompatibility, stability and sensitivity.

Research in these fields is of great significance in promoting the development of chip manufacturing technology and improving chip performance and reliability. At the same time, with the continuous advancement and innovation of science and technology, new research fields and technical directions may emerge in the future.

What are the current research results on electronic component chip materials?

Research on electronic component chip materials has currently achieved many important research results. Here are some of the main results:

Applications of graphene films

Graphene is a two-dimensional carbon material with excellent electrical conductivity and mechanical strength. In the research of electronic component chip materials, graphene films are used as gate materials, which can greatly improve the performance and reliability of the chip.

Application of new semiconductor materials

With the continuous development of science and technology, new semiconductor materials such as gallium nitride and silicon carbide are constantly emerging. These materials have the advantages of higher electron saturation mobility and better high temperature resistance, and can be used in high-performance electronic component chips.

Application of nanowire materials

Nanowires are one-dimensional nanomaterials with excellent properties that can be used to manufacture high-performance electronic component chips. For example, nanowires can be used to create smaller, faster transistors.

Research on flexible electronic component chips

With the rise of flexible electronic products such as wearable devices and flexible displays, the research on flexible electronic component chips has also become a hot topic. At present, some research teams have successfully developed flexible electronic component chips, which can be used in wearable devices, smart homes and other fields.

Research on electronic component chip materials is constantly making new progress, providing more possibilities for future electronic component chip manufacturing.

What is the development trend of electronic component chip materials?

The development trends of electronic component chip materials are mainly reflected in the following aspects:

Nanoization

With the continuous development of nanotechnology, the size of electronic component chip materials is getting smaller and smaller, and their performance is getting higher and higher. In the future, nanotechnology will become an important development trend in chip materials for electronic components.

Flexibility

With the rise of flexible electronic products such as wearable devices and flexible displays, the demand for flexible electronic component chip materials is increasing. In the future, flexibility will become an important development trend in chip materials for electronic components.

Intelligent

With the continuous development of technologies such as artificial intelligence and the Internet of Things, intelligent electronic component chip materials will become an important trend in the future. Intelligent electronic component chip materials can realize the perception and adaptive adjustment of the surrounding environment, improving the intelligence level of the equipment.

High performance

As the performance of electronic equipment continues to improve, the performance requirements for electronic component chip materials are also getting higher and higher. In the future, high-performance electronic component chip materials will become an important development trend.

Environmental protection

With the continuous improvement of environmental awareness, the environmental performance requirements for electronic component chip materials are also getting higher and higher. In the future, environmentally friendly electronic component chip materials will become an important development trend.

The development trend of electronic component chip materials is multi-faceted, including nanotechnology, flexibility, intelligence, high performance and environmental protection. These trends will promote the continuous development of electronic component chip materials and provide more possibilities for the future electronics industry.