Research on aging of plastic encapsulated microcircuit

The research on the aging of plastic-encapsulated microcircuits aims to explore the mechanism and rules of performance degradation of plastic-encapsulated microcircuits during long-term use, and provide theoretical support for extending the service life of microcircuits.

Introduction

In today’s highly automated electronics manufacturing world, the performance stability of microcircuits is critical. As one of the important forms, plastic microcircuit is widely used in various electronic devices.

However, plastic-encapsulated microcircuits may have potential early failure issues due to various factors during the manufacturing process.

Therefore, it is particularly important to age plastic-encapsulated microcircuits to detect and eliminate potential early failure factors in advance. This article will discuss in detail the principles, methods, technological progress and challenges of plastic microcircuit aging.

The principle of aging of plastic encapsulated microcircuit

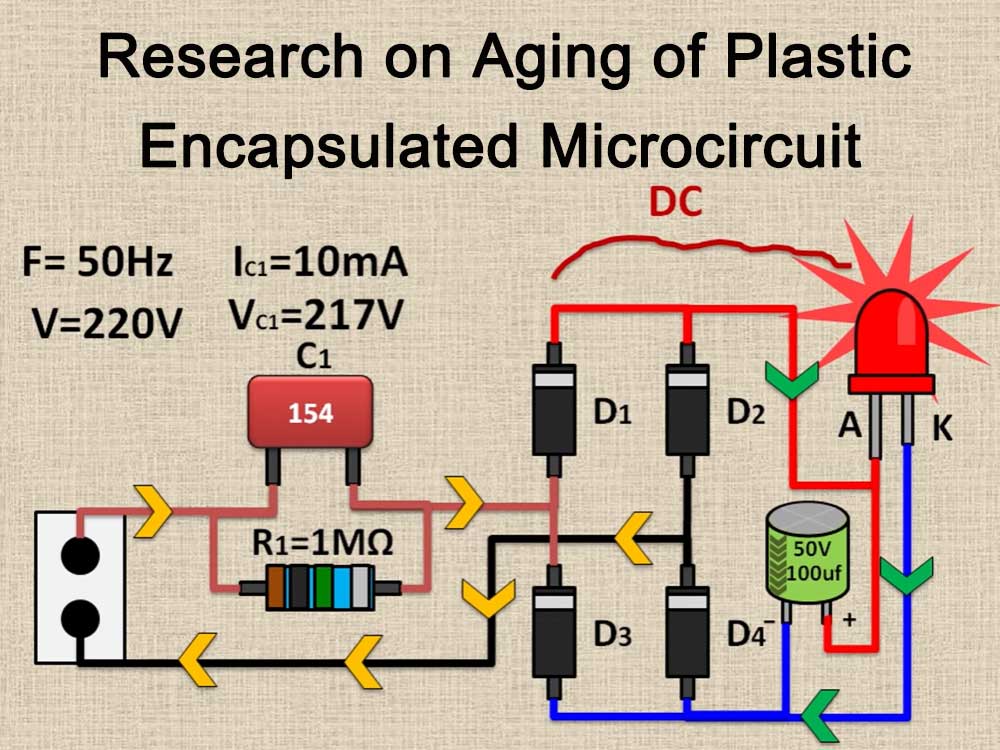

Aging refers to the process of accelerating the exposure of potential early failure factors by applying certain stress conditions after the electronic components are manufactured. For plastic-encapsulated microcircuits, aging usually includes temperature stress, electrical stress, etc. Through aging, potential early failure factors can be discovered and eliminated in advance, and the reliability and stability of microcircuit can be improved.

Methods for aging plastic microcircuits

- Temperature cycle aging: Temperature cycle aging is a commonly used aging method. In this method, plastic-encapsulated microcircuits are exposed to a range of high and low temperatures to simulate temperature changes in actual use. In this way, the adaptability of plastic-encapsulated microcircuits to temperature changes and potential thermal stress issues can be detected.

- Electric stress aging: Electric stress aging is to detect changes in the electrical properties of plastic-encapsulated microcircuits by applying a certain amount of electrical stress. This method can detect potential electrical problems in plastic microcircuits, such as electromigration, arcing, etc.

- Comprehensive aging: In addition to temperature cycle and electrical stress aging, comprehensive aging can also be carried out in combination with other stress conditions, such as mechanical stress, humidity, etc. Comprehensive aging can more comprehensively simulate the actual use environment and more accurately detect potential problems with plastic-encapsulated microcircuits.

Technological progress in plastic encapsulated microcircuit aging

With the continuous development of science and technology, the aging technology of plastic encapsulated microcircuit is also constantly improving. For example, the emergence of new testing equipment makes it possible to conduct high-precision electrical performance testing of plastic microcircuits; the development of new analysis tools can help engineers more accurately identify and locate problems in plastic microcircuits; in addition, artificial intelligence and Machine learning technology is also increasingly used in plastic microcircuit aging. They can help engineers analyze data more quickly, predict potential failure modes, and provide corresponding optimization suggestions.

Challenges and prospects of plastic microcircuit aging

Although plastic microcircuit aging technology has made great progress, it still faces some challenges. For example, how to more accurately simulate the aging conditions of the actual use environment, how to improve the efficiency of aging, and how to reduce the cost of aging, etc. In order to solve these problems, future research work can be carried out from the following aspects: first, in-depth study of the failure mechanism of plastic microcircuit to more accurately identify and locate potential problems; second, develop more efficient aging methods and equipment , to improve aging efficiency and reduce costs; finally, combine new technologies such as artificial intelligence and machine learning to develop an intelligent aging system to achieve automated aging and analysis.

Summarize

By aging the plastic-encapsulated microcircuit, its reliability and stability can be effectively improved. In order to carry out aging better, we need to continue to conduct in-depth research and explore new aging methods and equipment. In the future, with the continuous development of science and technology, we look forward to achieving more breakthroughs and innovations in the field of plastic microcircuit aging.

Frequently Asked Questions and Answers on Plastic Microcircuit Burning Research

Plastic microcircuit aging is a process that accelerates the exposure of potential early failure factors of microcircuits by simulating the stress conditions in the actual use environment.

Answer: The main purpose of aging plastic microcircuits is to improve the reliability and stability of microcircuits and to discover and eliminate potential early failure factors in advance. Through aging, the risk of early product failure can be reduced and the quality and reliability of the product can be improved.

Common plastic microcircuit aging methods include temperature cycle aging, electrical stress aging, and mechanical stress aging. These methods can test microcircuit performance and potential problems in different environments by applying different stress conditions.

The basic principle of aging plastic microcircuits is to accelerate the exposure of potential problems in microcircuits by applying certain stress conditions. These stress conditions can include temperature, electrical stress, mechanical stress, etc. to simulate the environmental conditions in actual use.

Temperature cycle aging simulates the temperature changes in actual use by exposing the microcircuit to high and low temperatures. In this way, thermal performance and thermal stress issues of microcircuits can be detected, as well as their reliability and stability evaluated at different temperatures.

Electrical stress aging is to detect changes in the electrical performance of microcircuits by applying a certain amount of electrical stress. This method can detect potential electrical problems in microcircuits, such as electromigration, arcing, etc. Through electrical stress aging, the stability and reliability of microcircuit under different operating voltages and currents can be evaluated.

Research on the aging of plastic microcircuits has made some progress, but it still faces some challenges and problems. Future development trends include the development of more efficient aging methods and equipment, in-depth research on the failure mechanisms of microcircuits, and the combination of new technologies such as artificial intelligence and machine learning to achieve more accurate and efficient aging analysis and evaluation. At the same time, as the requirements for reliability and stability of electronic products continue to increase, plastic microcircuit aging technology will be more widely used and valued.