Research on manufacturability of electronic components

With the continuous development of science and technology, electronic components are used more and more widely in various fields.

In order to meet market demand, electronic component manufacturing companies need to continuously improve production efficiency and product quality.

Therefore, research on the manufacturability of electronic components has become increasingly important. This article will provide a detailed introduction to the research on manufacturability of electronic components, including its research significance, main content, methods and technologies.

What is electronic component manufacturability

Manufacturability of electronic components refers to the feasibility, stability and reliability of components during the production process. It involves every aspect from design, material selection to process flow, ensuring that products can be put into production efficiently and at low cost.

In-depth research on the manufacturability of electronic components can help improve production efficiency, optimize product design, and reduce production costs.

Why does electronic component manufacturability exist

The significance of the manufacturability of electronic components is mainly reflected in the following aspects:

Solve manufacturing problems

The manufacturing process of electronic components involves many complex issues, such as process control, material selection, equipment accuracy, etc. Manufacturability research is to solve these manufacturing problems and ensure that components can be produced efficiently, stably and reliably.

Improve production efficiency

By optimizing the manufacturing process, reducing production links, and improving the accuracy and reliability of production equipment, the production efficiency of electronic components can be significantly improved and production costs reduced.

Improve product quality

The quality of electronic components directly affects the performance and stability of the entire electronic system. Manufacturability research improves the performance indicators and stability of components by optimizing design, material selection and manufacturing processes, thereby improving the quality of the entire electronic product.

Meet market demand

With the rapid development of electronic technology, the market demand for electronic components is increasing, and the performance and quality requirements for components are also getting higher and higher. Manufacturability research optimizes design, material selection and manufacturing processes based on market demand to meet market demand for high-quality, high-performance components.

Promote technological innovation

Research on the manufacturability of electronic components requires continuous exploration of new manufacturing technologies and process methods to solve problems and challenges in the manufacturing process.

These studies promote the innovation and development of related technologies and provide impetus for the progress of electronic manufacturing.

To sum up, the manufacturability of electronic components exists to solve manufacturing problems, improve production efficiency, improve product quality, meet market demand and promote technological innovation.

Through in-depth research on the manufacturability of electronic components, the competitiveness and development level of the electronics manufacturing industry can be continuously improved.

What chemical elements should be considered for the manufacturability of electronic components

The manufacturability of electronic components mainly focuses on the following aspects when considering chemical elements:

Active elements

Such as lithium, sodium, potassium, magnesium, aluminum, etc. They may react chemically with other materials during the manufacturing process of electronic components, affecting the performance and stability of the product.

Semi-metal elements

Such as silicon, germanium, etc. These elements are commonly used as semiconductor materials in the manufacturing of electronic components. Their doping concentration and distribution have an important impact on the performance of electronic components.

Metalloid elements

Such as boron, phosphorus, arsenic, etc. These elements are often used as dopants in semiconductor manufacturing to change the conductive properties of semiconductors.

Gas elements

Such as nitrogen, oxygen, hydrogen, etc. These gases may react chemically with materials during the manufacturing process of electronic components to form compounds, affecting the performance and stability of the product.

Metal elements

Such as copper, silver, gold, etc. These metal elements are commonly used as electrodes and conductive materials in the manufacturing of electronic components. Their purity and surface treatment have an important impact on the performance and stability of the product.

In addition, the manufacturability of electronic components also needs to consider the compatibility of chemical elements, that is, the selected chemical elements should be compatible with the manufacturing process and materials to avoid chemical reactions or the production of harmful substances during the manufacturing process, which will affect the performance of the product. and stability.

At the same time, the toxicity of chemical elements and environmental protection requirements need to be considered to comply with relevant regulations and standards.

What materials should be considered for electronic component manufacturability

When considering the manufacturability of electronic components, you need to pay attention to the following material factors:

Physical and chemical properties of materials

This includes physical properties such as electrical conductivity, thermal conductivity, corrosion resistance, strength, hardness, etc., as well as chemical properties such as compatibility with various chemical reagents and corrosion resistance. . These properties have an important impact on the performance and service life of components.

Machinability of materials

This includes the plasticity, weldability, cutability, etc. of the material during the manufacturing process. Easily processed materials can increase production efficiency and reduce manufacturing costs.

Environmental adaptability of materials

For automotive electronic components, materials must be able to work stably in various harsh environments, including high temperature, low temperature, humidity, salt spray and other environments.

Cost of Materials

Under the premise of meeting performance requirements, lower-cost materials should be selected as much as possible to reduce the overall cost of the product.

Recyclability of materials

For some special materials, it is necessary to consider whether they are easy to recycle and dispose after the end of their service life to comply with environmental protection requirements.

Material supply chain

It is necessary to consider whether the material supply chain is reliable, whether there are stable suppliers, and whether the material supply is timely.

Safety of materials

Some materials may have potential safety risks, such as toxic substances, flammable substances, etc. When selecting materials, full consideration needs to be given to their safety.

In summary, in order to ensure the manufacturability of electronic components, comprehensive consideration and evaluation must be carried out in terms of the physical and chemical properties of the material, processability, environmental adaptability, cost, recyclability, supply chain, and safety. .

What are the requirements for physical changes for the manufacturability of electronic components

The requirements for physical changes for the manufacturability of electronic components are mainly reflected in the following aspects:

Dimensional Stability

During the manufacturing process, the dimensions of electronic components should remain stable to ensure product consistency and reliability. Any dimensional changes can cause assembly issues or affect component performance.

Structural Integrity

During the manufacturing process, the structure of electronic components should be able to withstand the mechanical stress and thermal stress during various processes without fracture, deformation or damage.

Thermal Stability

During the manufacturing process, electronic components should be able to withstand various temperature changes without thermal expansion or contraction, resulting in changes in structure or performance.

Corrosion resistance

During the manufacturing process, electronic components should have a certain degree of corrosion resistance to cope with possible chemical corrosion or environmental corrosion.

Insulation

For some electronic components, such as capacitors, resistors, etc., it is necessary to maintain a certain insulation performance to avoid safety issues such as leakage and electric shock.

Magnetic Stability

For some electronic components involving magnetic materials, magnetic stability is an important consideration. During the manufacturing process, the stability and consistency of magnetic material performance should be ensured.

To sum up, the requirements for physical changes in the manufacturability of electronic components are mainly reflected in aspects such as dimensional stability, structural integrity, thermal stability, corrosion resistance, insulation and magnetic stability.

These requirements are to ensure that the performance and quality of electronic components during the manufacturing process remain stable and reliable.

The significance of research on manufacturability of electronic components

Research on the manufacturability of electronic components aims to improve the manufacturing efficiency and product quality of electronic components, reduce production costs, and provide strong support for the sustainable development of enterprises.

Specifically, the significance of research on the manufacturability of electronic components is reflected in the following aspects:

Improve production efficiency

Good manufacturability design can make electronic components easier to manufacture, reduce problems and failures during the manufacturing process, thereby improving production efficiency.

Reduce manufacturing costs

By optimizing design, reducing manufacturing difficulty and reducing waste in the manufacturing process, manufacturing costs can be reduced and the market competitiveness of products can be improved.

Ensure product quality

Good manufacturability design can reduce defects and errors in the manufacturing process, thereby improving product quality and reducing product failure rates.

Shorten the R&D cycle

By considering manufacturability in the design stage, the design modification and optimization work during the manufacturing process can be reduced, thereby shortening the product R&D cycle.

Improve supply chain management efficiency

Good manufacturability design can optimize the selection of materials and processing technology, making the supply chain more reliable and efficient.

Meet customer needs

Producing high-quality products quickly and efficiently can help manufacturing plants better meet customer needs and improve customer satisfaction.

Promote enterprise innovation

By optimizing product design and improving product manufacturability, the innovation vitality of enterprises can be stimulated and the enterprise can be promoted to continuous progress.

In summary, the manufacturability of electronic components is important for electronic component manufacturing factories to improve production efficiency, reduce manufacturing costs, ensure product quality, shorten R&D cycles, improve supply chain management efficiency, meet customer needs and promote corporate innovation. significance.

Therefore, manufacturability should be fully considered during the product design stage to ensure product reliability and reduce manufacturing costs.

Main contents of manufacturability research of electronic components

Research on manufacturability of electronic components mainly includes the following aspects:

Manufacturability research in the design stage

During the design stage, factors such as manufacturing costs, process flows, and production cycles of electronic components are evaluated and optimized to ensure that the product has good manufacturability.

Rationality research on material selection

Select appropriate materials based on product performance requirements and manufacturing processes, and evaluate their processing performance, stability, reliability, etc.

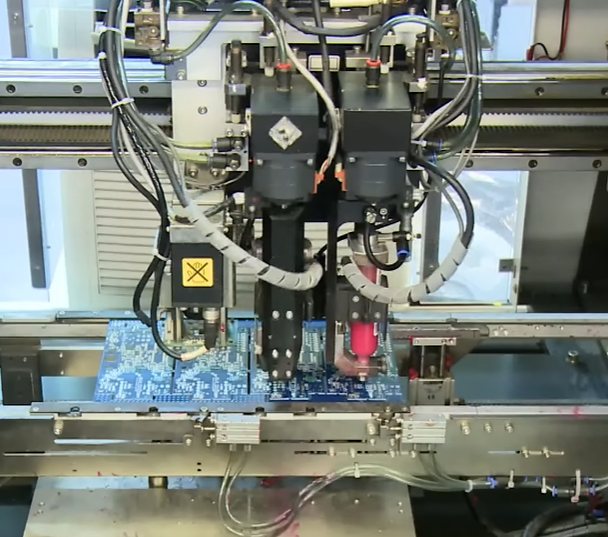

Optimization research of process flow

Through in-depth research and analysis of the manufacturing process, the process flow is optimized, production efficiency is improved, and production costs are reduced.

Research on quality and reliability

In manufacturability research, research on quality and reliability is a very important aspect. Through product quality testing, reliability analysis and other means, we ensure that products have good performance and stability.

Research on production environment and equipment

Production environment and equipment have a great impact on the manufacturability of electronic components. Ensure that products can be manufactured under appropriate conditions by studying the requirements of the production environment and the selection of equipment.

Methods and technologies for manufacturability research of electronic components

Methods and technologies for electronic component manufacturability research mainly include the following aspects:

Manufacturing process research

It mainly focuses on how to control the performance indicators of components. For example, the manufacturing process in semiconductor technology, whether it is deposition, etching, adhesion or annealing, has very high technical requirements.

Research on material properties

Copper bus bars in electronic conductors are widely used with the improvement of precision, thinning of metal and increase in density.

In addition, for electronic components, the selection of materials is also very important, and factors such as physical, chemical, and mechanical properties of the materials, as well as manufacturing costs, need to be comprehensively considered.

Reliability research

The reliability of electronic components is an important indicator of their quality and an important reflection of their manufacturability. Reliability research includes environmental adaptability, life prediction, failure analysis, etc.

Experimental design method

Experiment and analyze various factors through the experimental design method to determine the best process parameters and material combinations.

Numerical simulation method

Use numerical simulation software to simulate and analyze the manufacturing process of electronic components to predict product performance and reliability.

Data analysis method

Use data analysis tools to analyze and mine experimental data to find out the key factors that affect product performance and reliability.

Expert system method

Use expert systems to conduct intelligent analysis and decision support for the manufacturing process of electronic components.

Reliability engineering

Reliability engineering is one of the important technologies in the study of manufacturability of electronic components. By analyzing and evaluating product reliability, potential problems and improvement directions can be identified to improve product reliability and stability.

The above methods and technologies are important means for research on the manufacturability of electronic components.

They can help researchers better understand the problems and challenges existing in the manufacturing process, optimize the manufacturing process, improve production efficiency, and reduce production costs.

The future of electronic component manufacturability research

Research on the manufacturability of electronic components is one of the important means to improve enterprise production efficiency and product quality.

Through in-depth research on market demand and product development trends, optimizing design, material selection, process flow, etc., we can reduce production costs, improve production efficiency, improve product quality, and provide strong support for the development of enterprises.

In the future, with the continuous development of science and technology, research on the manufacturability of electronic components will become more in-depth and comprehensive, providing more opportunities and challenges for the innovation and development of enterprises.