PNG memory IC refers to a memory chip encoded using the PNG (Pantone Numbering System) color standard.

The PNG color standard is a color matching system for accurately matching colors on different printing and digital display devices. This color standard is widely used in printing, advertising, design and other fields.

In the field of memory ICs, chips encoded with the PNG color standard are often used in color sensors or image processing equipment. These chips convert color information into digital signals for further processing and analysis. Encoded using the PNG color standard, these chips are able to provide more accurate and consistent color matching, thereby improving the accuracy and effectiveness of image processing.

It should be noted that the specific applications and performance of PNG memory ICs may vary between different manufacturers and models. Therefore, when selecting and using, it is recommended to evaluate and select based on specific application needs and product specifications.

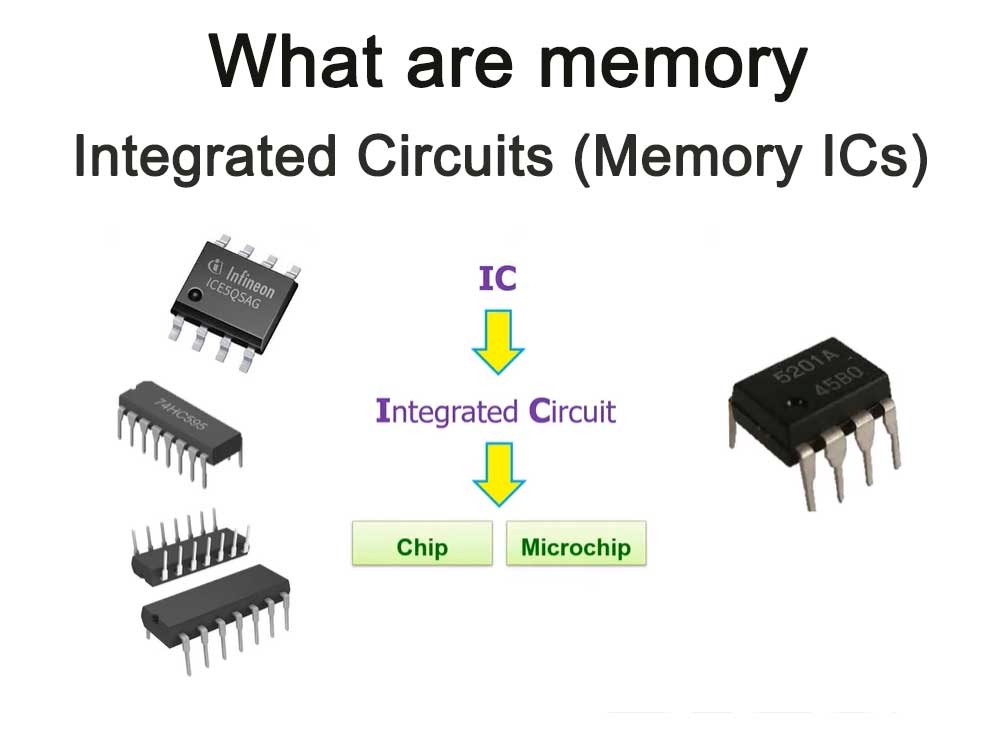

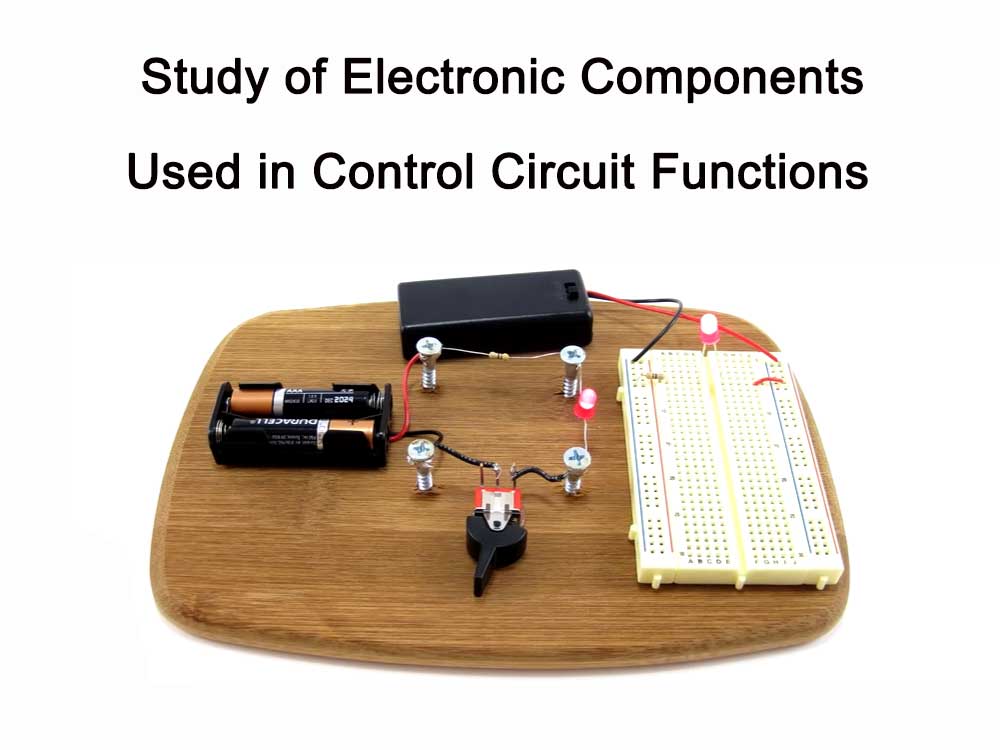

What is memory?

Memory is one of the most important components in the computer. It is the bridge between the program and the CPU.

All programs in the computer run in the memory, so the memory has a great impact on the computer. The memory is also called the main memory. Its function is to store the calculation data in the CPU and exchange it with external storage devices such as hard disks. data.

As long as the computer is running, the CPU will transfer the data that needs to be calculated to the main memory for calculation. When the calculation is completed, the CPU will transmit the results. The operation of the main memory also determines the stable operation of the computer.

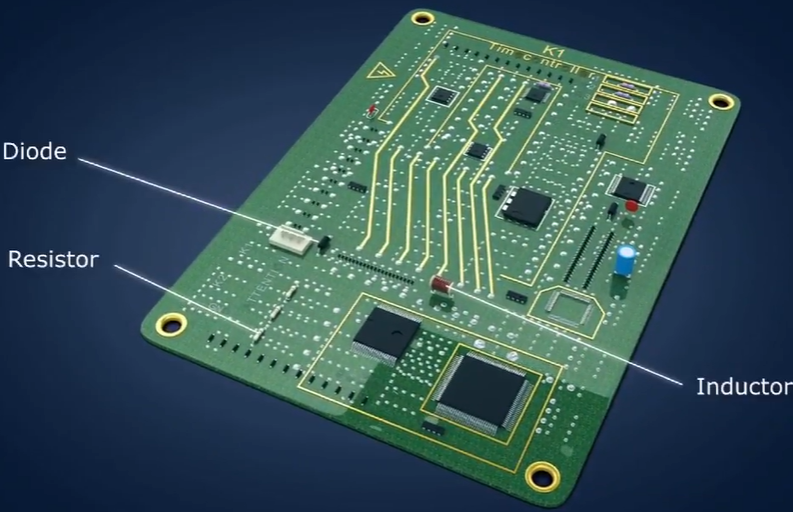

Physical structure of memory

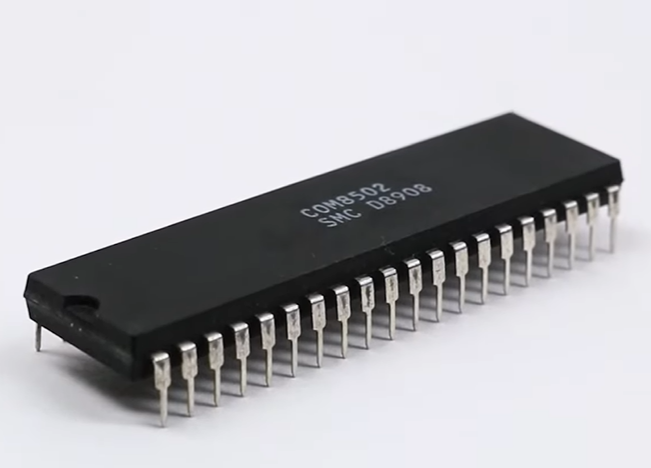

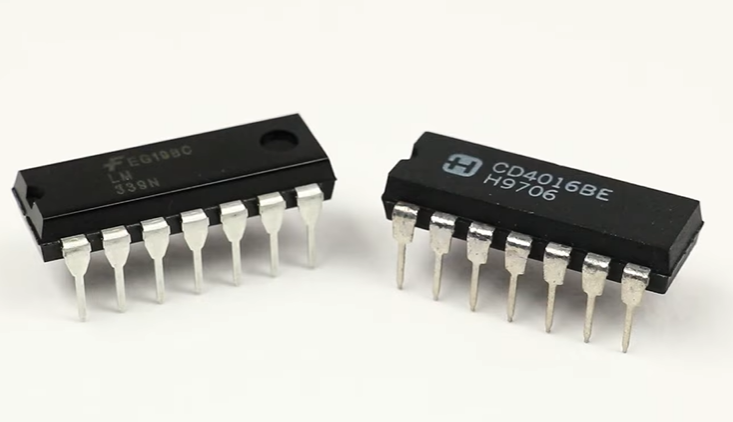

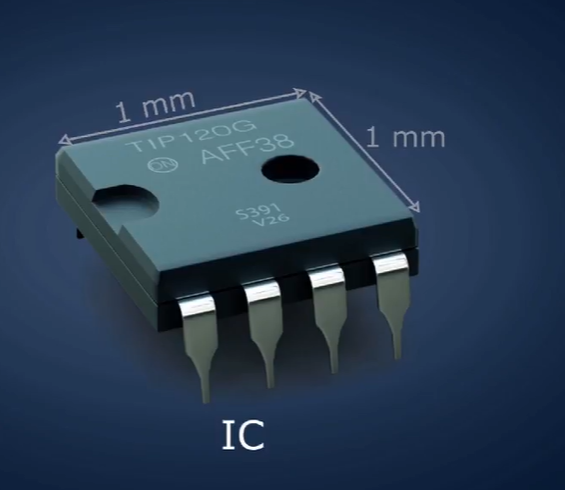

The interior of memory is composed of various IC circuits. There are many types of memory, but it is mainly divided into three types of memory:

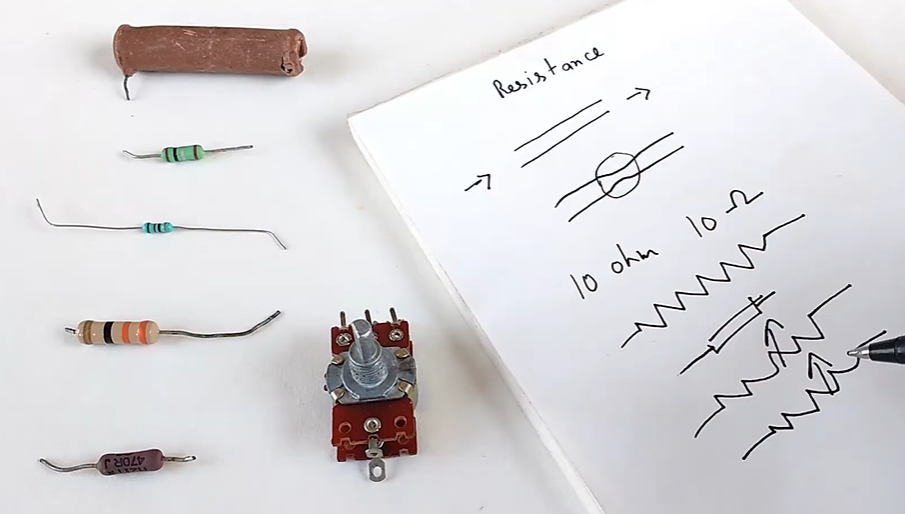

Random access memory (RAM): The most important type of memory, meaning that data can be read from and written to. When the machine is turned off, the information in memory is lost.

Read-only memory (ROM): ROM can generally only be used to read data and cannot write data, but when the machine loses power, the data will not be lost.

Cache: Cache is something we often see. It is divided into level one cache (L1 Cache), level two cache (L2 Cache), and level three cache (L3 Cache). It is located between the memory and the CPU. , is a memory that reads and writes faster than memory. When the CPU writes data to memory, the data is also written to the cache. When the CPU needs to read data, it will read it directly from the cache. Of course, if the required data is not in the cache, the CPU will read the data in the memory.

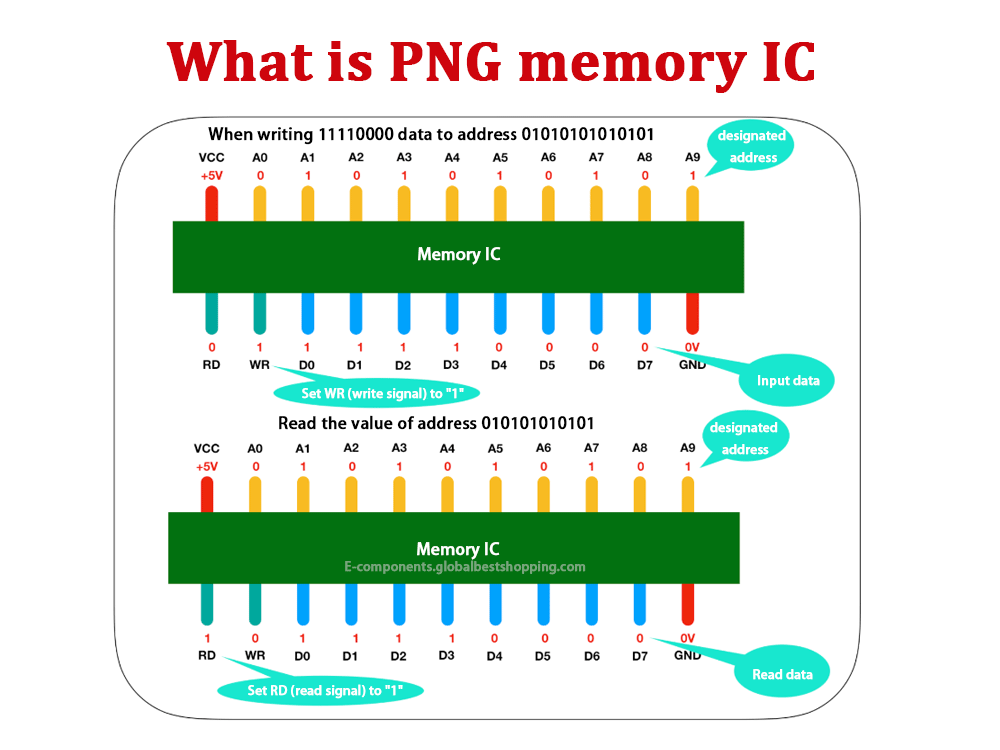

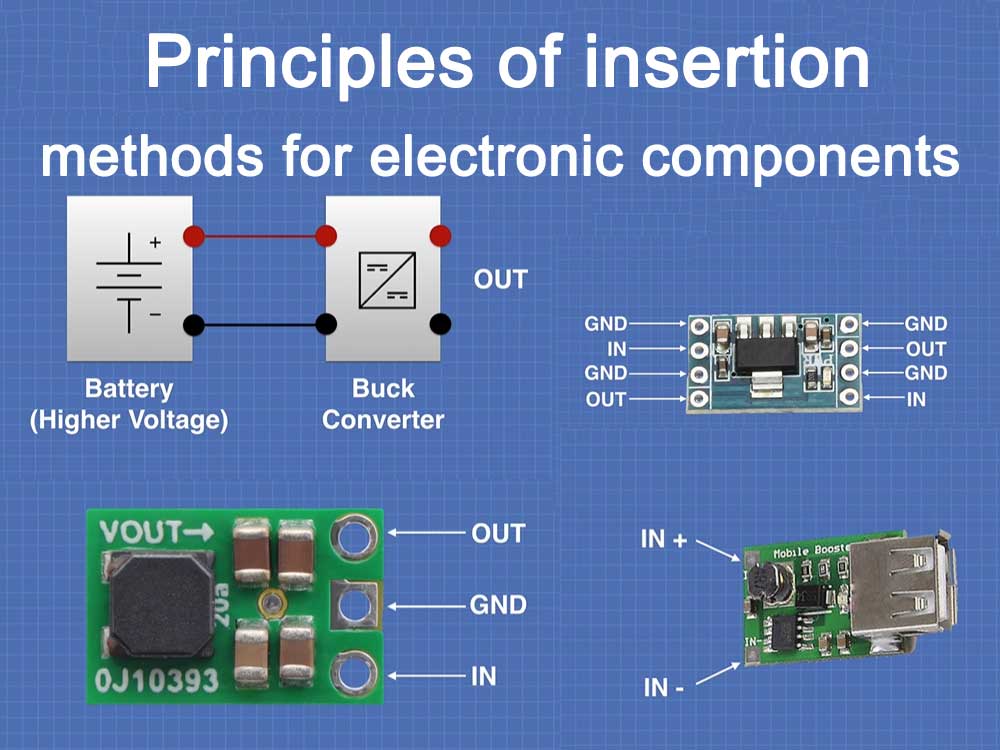

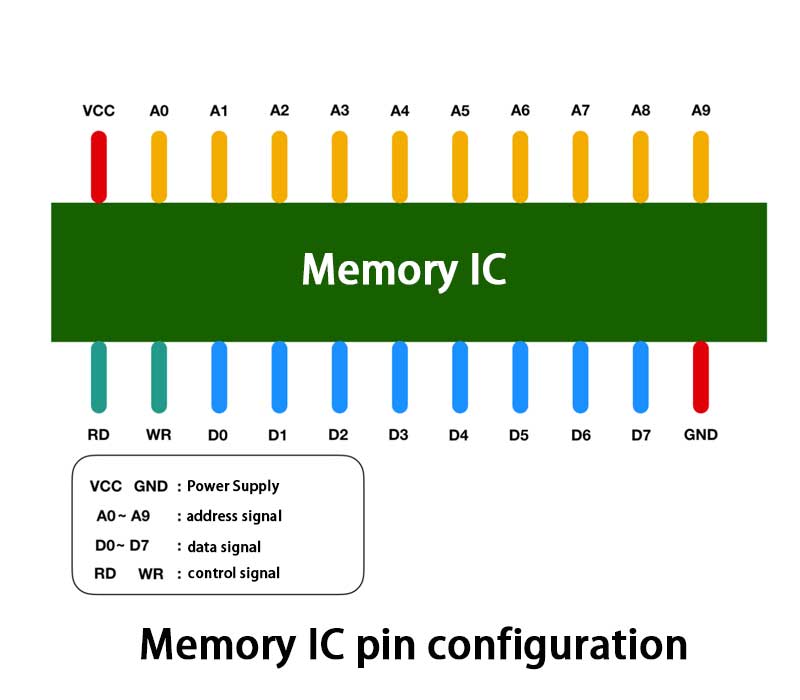

The memory IC is a complete structure. It also has power supply, address signals, data signals, control signals and IC pins for addressing to read and write data. Here is a virtual IC pin diagram:

In the picture, VCC and GND represent the power supply, A0 – A9 are the address signal pins, D0 – D7 represent the control signal, RD and WR are good control signals. I use different colors to distinguish them, and connect the power supply to VCC and GND, you can pass 0 and 1 signals to other pins. In most cases, +5V means 1, and 0V means 0.

We all know that memory is used to store data, so how much data can be stored in this memory IC? D0 – D7 represent data signals, that is to say, 8 bit = 1 byte of data can be input and output at one time. A0 – A9 are ten address signals in total, which means that 00000 00000 – 11111 11111 can be specified, a total of 2 to the 10th power = 1024 addresses.

Each address stores 1 byte of data, so we can conclude that the capacity of the memory IC is 1 KB.

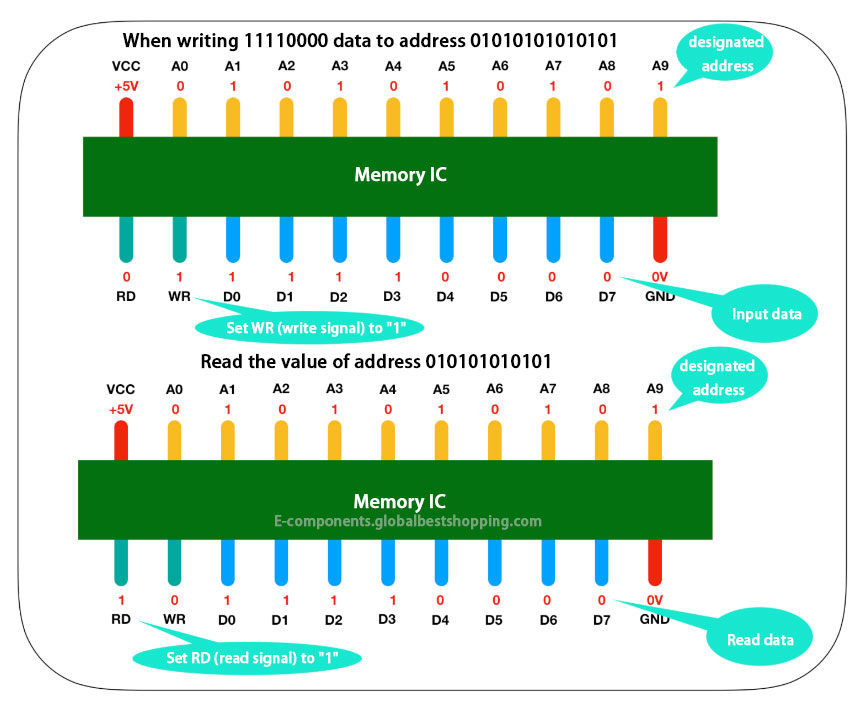

Memory reading and writing process

Let us focus on the process of reading and writing data by the memory IC! Let’s look at a model for writing and reading data to a memory IC

What is PNG memory ic used for?

PNG Memory IC is a storage device used to store data, similar to a computer’s hard drive or a mobile phone’s memory. It uses the PNG (Portable Network Graphics) format to store data, usually in the form of a flash drive or memory card.

Specifically, PNG memory IC can be used in the following scenarios:

- Data backup and recovery: Back up important data to PNG memory IC, which can restore data when the data is lost or damaged.

- Storage and transmission: Similar to other storage devices, data such as files, pictures, videos, etc. can be stored in the PNG memory IC and transmitted when needed.

- Expanded storage space: For some devices, such as digital cameras, tablets, etc., PNG memory IC can be used as extended memory to increase the storage capacity of the device.

- Encryption and security: Some PNG memory ICs have encryption functions to protect the security and privacy of data.

In short, PNG memory IC is a storage device used to store and transmit data and has a wide range of application scenarios.

How about PNG memory stick?

PNG memory sticks refer to memory sticks using the PNG (Portable Network Graphics) format. However, in current computer hardware, PNG format memory sticks are not used because PNG is an image file format, not a hardware device for storing data.

The memory stick in a computer usually refers to RAM (Random Access Memory), which is a temporary memory in the computer used to store running programs and data. RAM formats and standards are dictated by the computer hardware industry, not image file formats.

Therefore, the issue of “PNG memory stick” is actually a misunderstanding or confusion. PNG is just an image file format, and it is two completely different concepts from the computer’s memory stick. Therefore, it is impossible to make a specific evaluation or comparison of the “PNG memory module” because it is not an actual hardware device.

What are the advantages of PNG memory ICs?

The advantages of PNG memory ICs may include the following aspects:

- Portability: PNG is a widely used image file format that can be easily opened and edited in various operating systems and software. Therefore, using PNG format memory cards or flash drives makes it easy to transfer and share data between different devices and software.

- Compatibility: PNG is a lossless compression format that can retain the complete quality of the image and avoid image distortion or quality degradation. This makes PNG memory ICs highly compatible and reliable when storing and transmitting high-definition images.

- Security: The PNG format supports transparency and alpha channels, allowing you to create images with complex backgrounds and transparency. This makes PNG memory ICs somewhat secure when storing and transmitting sensitive data, as data visualization and access rights can be better controlled.

- Efficiency: PNG is an efficient image file format that can reduce file size and storage space while ensuring image quality. This makes the PNG memory IC more efficient when storing large amounts of image data, saving storage resources and transmission costs.

It should be noted that the above advantages are only some possible aspects, and the specific advantages depend on the actual application scenarios and needs.

What are the disadvantages of PNG memory ICs?

Disadvantages of PNG memory ICs may include the following:

- Compatibility issues: Although PNG is a widely used image file format, there may be compatibility issues in some specific fields or software. For example, some older software or operating systems may not be able to correctly recognize or open PNG files.

- Insufficient animation support: The PNG format does not support animation effects. Compared with other dynamic image formats (such as GIF or MP4), it has limitations in expressing dynamic content.

- Relatively large file size: Compared with some other image formats (such as JPEG), the file size of the PNG format is usually larger, which may affect storage space usage and transmission efficiency.

- Transparency problem: Although PNG supports transparency settings, in some cases there may be problems with improper transparency processing or transparency not matching the background, which may affect the overall effect of the image.

It should be noted that the above disadvantages are only some possible aspects, and the specific disadvantages depend on the actual application scenarios and requirements. When choosing to use a PNG memory IC, you need to weigh its advantages and disadvantages based on actual needs.

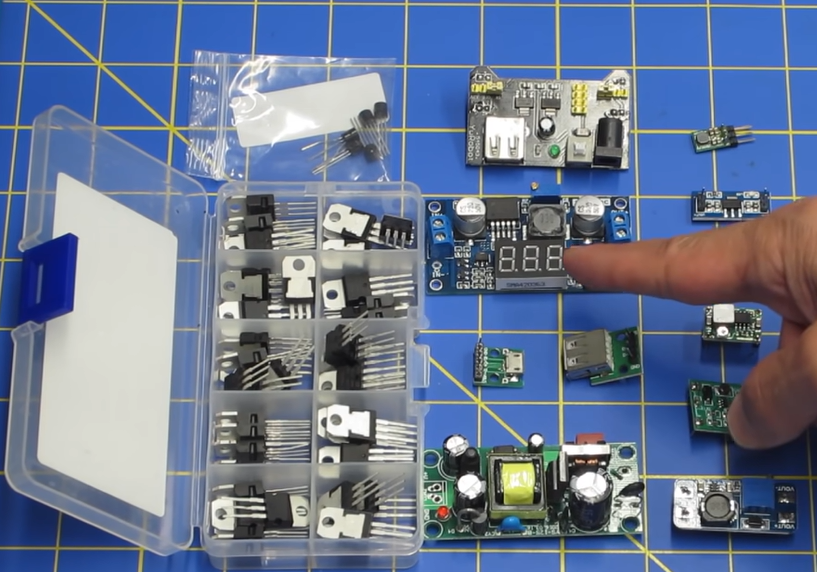

PNG Memory IC main types

There are two main types of PNG memory ICs: static random access memory (SRAM) and dynamic random access memory (DRAM).

SRAM is faster and more expensive than DRAM. DRAM is cheaper than SRAM, but slower.

What are the uses of PNG memory ICs?

PNG memory ICs are used in a variety of applications including:

- Store code and data

- Cached data

- Provide storage capacity

- Improve performance

PNG Memory ICs are used in mobile devices, computers and other electronic devices. They are used to store code, data, and other information required by the application. PNG memory ICs are also used to cache data to improve performance.

PNG What is the future of memory ICs?

The market for PNG memory ICs is expected to continue growing in the coming years. This is mainly due to the popularity of mobile devices and other electronic devices. PNG memory ICs will also benefit from the adoption of emerging technologies such as artificial intelligence and machine learning.

PNG memory IC manufacturer

- Samsung Electronics

- Micron Technology

- Texas Instruments

- Intel

- Toshiba

- Sony

- Renesas Electronics

- Fujitsu