Cook Cooper Smart Capacitor Operation Guide: From installation to maintenance, we provide you with detailed operating guidance to ensure the safe and stable operation of the capacitor and effectively improve the performance of the power system.

Overview of Cook Cooper Smart Capacitors

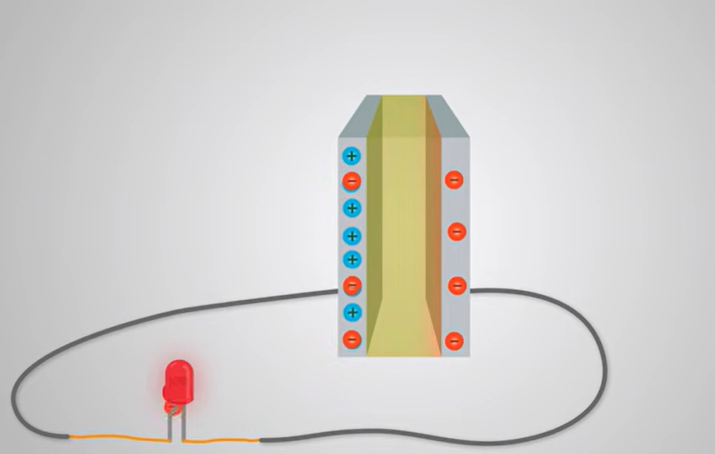

Cook Cooper smart capacitor is a power electronic device used for reactive power compensation and filtering. It integrates modern power electronics technology and intelligent control algorithms, which can dynamically adjust reactive power and active power to improve the stability of the power system, reduce energy consumption and improve power quality.

This operating guide is intended to provide users with detailed operating guidance on Cook Cooper smart capacitors.

Cook Cooper Smart Capacitor Installation

- Confirm the capacitor installation environment: Make sure the capacitor is installed in a dry, well-ventilated environment without severe vibration or corrosive gases.

- Grounding: Reliably ground the metal shell of the capacitor to ensure safe operation.

- Cable connection: Use appropriate cables to connect the capacitor to the system, making sure the connection is firm and not loose.

- Inspection before operation: Check whether the capacitor wiring is correct and there is no short circuit, open circuit, etc.; check whether the appearance of the capacitor is intact and there is no damage, leakage, etc.

Cook Cooper Smart Capacitor Operation

- Put into operation: After confirming that the capacitor wiring is correct and the appearance is intact, put the capacitor into operation through the control switch.

- Out of service: When the capacitor needs to be out of service, it is removed from the system through the control switch.

- Parameter setting: According to actual needs, set parameters of the capacitor through controller or touch screen and other equipment, such as switching delay, compensation target, etc.

- Troubleshooting: When an abnormality occurs in the capacitor, it should be stopped immediately and inspected and repaired. For faults that cannot be eliminated, it is recommended to contact professionals for repair.

Cook Cooper Intelligent Capacitor Maintenance

- Regular inspection: Regularly inspect the capacitor, including whether the appearance is damaged, leaking, etc.; whether the wiring is loose; whether the control equipment is normal, etc.

- Cleaning and maintenance: Keep the capacitor and its surrounding environment clean, and regularly clean up dust and other debris to ensure good heat dissipation.

- Preventive tests: Conduct preventive tests regularly according to actual conditions, such as measuring insulation resistance, withstand voltage tests, etc., to ensure normal performance of the capacitor.

- Life assessment: Evaluate the life of the capacitor based on its operating conditions, and replace aging or damaged capacitors in a timely manner.

Precautions for Cook Cooper Smart Capacitors

- Safe operation: When operating capacitors, safety procedures should be followed to ensure that operators have appropriate electrical knowledge and operating skills.

- Overloading is prohibited: Avoid long-term operation exceeding the rated current of the capacitor to avoid equipment damage or safety accidents.

- Frequent switching is prohibited: Avoid frequent switching of capacitors to avoid unnecessary impact on the equipment.

- Regular calibration: Calibrate the control equipment regularly to ensure that its measurement and adjustment accuracy meets the requirements.

- Keep records: Record the operation and maintenance of capacitors to facilitate tracking and management of the status of the equipment.

Common faults of capacitors and their troubleshooting methods

- Abnormal noise from the capacitor: It may be caused by internal component failure or poor contact. It should be stopped immediately and inspected and repaired.

- Capacitor overheating: It may be caused by excessive operating current or poor heat dissipation. The operating current should be reduced or the heat dissipation conditions should be improved.

- Control equipment failure: It may be caused by equipment failure such as controllers and sensors. Relevant equipment should be inspected and repaired or replaced.

- No compensation effect: It may be caused by incorrect wiring, improper setting of control equipment or mismatched capacitor bank. Relevant equipment and wiring should be checked, parameter settings should be re-set or capacitor bank configuration should be adjusted.

Conclusion on Cook Cooper Smart Capacitors

This operating guide is intended to provide users with detailed operating guidance on Cook Cooper smart capacitors, to help users correctly use and maintain the equipment, and to ensure its safe and stable operation.

If you encounter problems during use, you can refer to this guide for troubleshooting and processing; if you cannot solve the problem, please contact professionals for repair and processing.