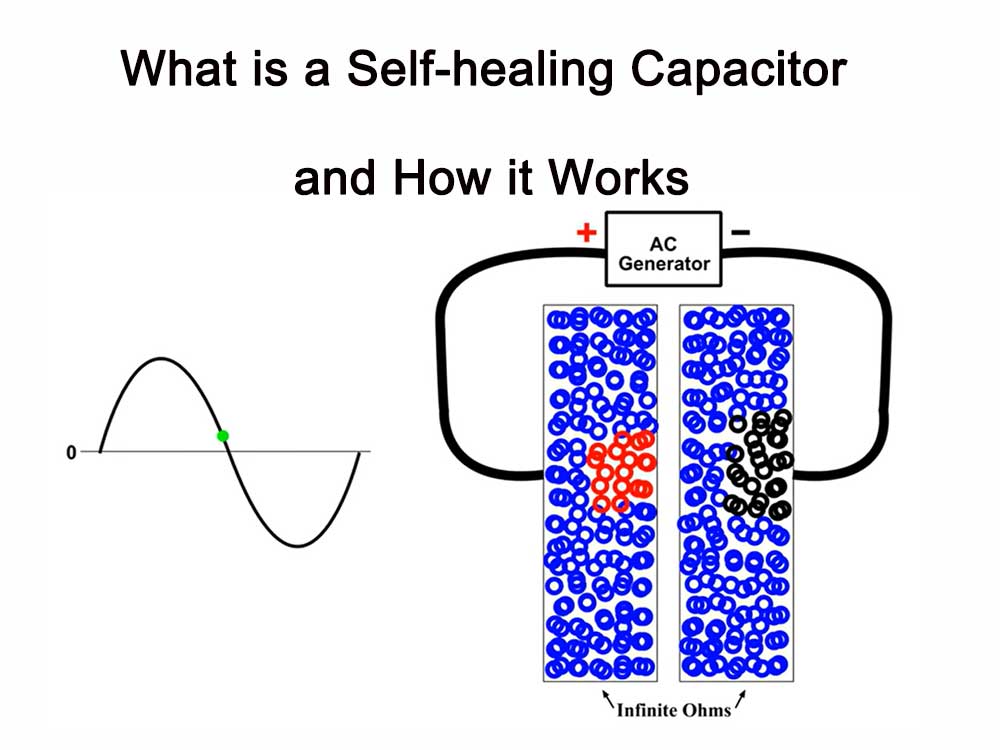

What is a self-healing capacitor and how it works

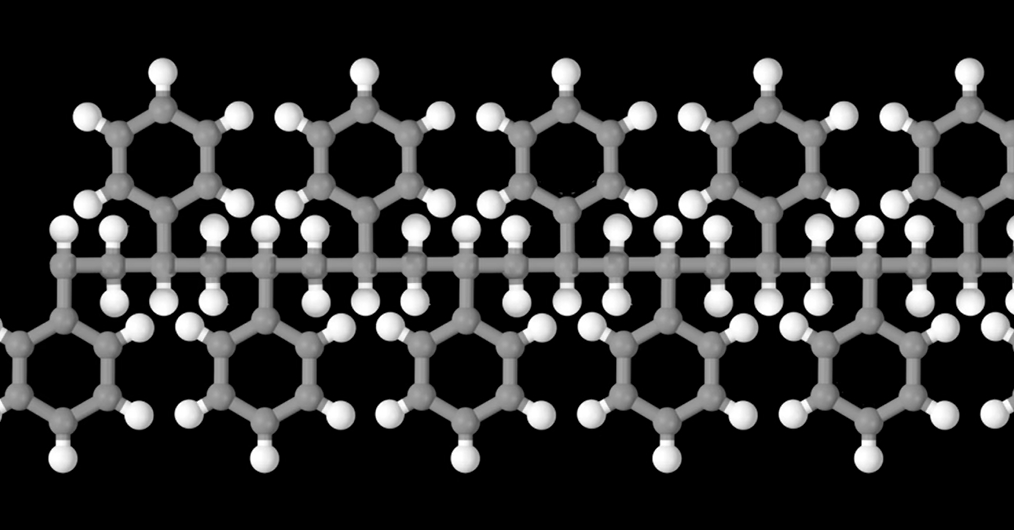

A self-healing capacitor is a power capacitor that uses a single layer of polypropylene film as the medium and a thin layer of metal evaporated on the surface as the conductive electrode.

After electrical breakdown occurs in the capacitor, the breakdown point can quickly restore insulation to ensure the safe operation of the power capacitor.

This self-healing process is due to the fact that when excessive voltage is applied, the electrical weakness of the polypropylene film is broken down, the impedance at the breakdown point is significantly reduced, and the current density flowing through increases sharply, causing the metallized coating to generate high heat, causing the breakdown point to The surrounding metal conductors quickly evaporate and escape, forming a blank area of the metal coating, and the breakdown point automatically restores the insulation. Self-healing power capacitors have the advantages of small size, light weight, large capacity, high reliability, and long life, and are widely used in power systems.

What is the principle of self-healing capacitor

The working principle of self-healing capacitors is based on the joint action of self-healing dielectric and capacitor structure. Self-healing dielectric is composed of a combination of metal foil and polypropylene film and has excellent self-healing properties.

When the capacitor is subject to breakdown or local failure caused by external factors, the self-healing dielectric can automatically recover and isolate the fault point, thereby ensuring the normal operation of the capacitor.

The structure of a self-healing capacitor usually includes metal foil electrodes, polypropylene film as a dielectric, and insulating oil filling. Under normal operating conditions, current passes through the dielectric layer between the metal foil electrode and the polypropylene film, producing a capacitive effect and storing electrical energy. When breakdown or failure occurs in the dielectric layer inside the capacitor, the self-healing dielectric can respond quickly and form a high-impedance area around the breakdown point to prevent the flow of current, thus automatically isolating the fault point. This process is realized by the self-healing characteristics of the self-healing dielectric, which can avoid short circuit or open circuit of the capacitor and maintain the normal operation of the capacitor.

The self-healing process of self-healing capacitors is transient and usually only takes a few microseconds to tens of microseconds. Therefore, self-healing capacitors have high reliability, stability and safety, and can adapt to the complex environment and various operating conditions of the power system. In power systems, self-healing capacitors are widely used in reactive power compensation, harmonic suppression, voltage regulation and other fields, providing an important guarantee for the stable operation of the power system.

In general, the working principle of self-healing capacitors is based on the excellent performance of self-healing dielectrics and the reasonable design of the capacitor structure. Through the self-healing process, automatic isolation and repair of faults are achieved, maintaining the normal operation of the capacitor and improving the reliability of the power system. sex and stability.

The difference between self-healing capacitors and non-self-healing capacitors

The difference between self-healing capacitors and non-self-healing capacitors is mainly reflected in the following aspects:

- Self-healing ability: Self-healing capacitors have self-healing ability and can repair themselves when breakdown occurs, ensuring the normal operation of the capacitor. Non-self-healing capacitors do not have this ability. Once they break down, they will cause a short circuit and cause damage to the capacitor.

- Structure: The structure of the self-healing capacitor is relatively simple. Polypropylene film is usually used as the medium. The metallized film is thin and has a large square resistance. The structure of non-self-healing capacitors is more complex. Aluminum foil or aluminum film is usually used as the electrode, and the dielectric materials are also diverse.

- Size and weight: Self-healing capacitors have the advantages of small size and light weight, and are easy to install and use. Non-self-healing capacitors, on the other hand, are generally larger and heavier, making them less suitable for use in environments with limited space.

- Operating temperature range: Self-healing capacitors have a wide operating temperature range and can operate stably in high temperature environments. Non-self-healing capacitors are easily affected by temperature and have a narrow operating temperature range.

- Price: The price of self-healing capacitors is relatively low because of their low manufacturing costs. Non-self-healing capacitors are more expensive because their manufacturing process is more complex.

Self-healing capacitors and non-self-healing capacitors each have their own advantages and disadvantages, and the choice of which capacitor to use needs to be determined based on actual needs. In situations where high reliability and stability are required and operation in high temperature environments is required, self-healing capacitors are a better choice; in situations where low cost, smaller size and weight are required, non-self-healing capacitors may be more popular. welcome.

Self-Healing Material – Analysis on the principle of self-healing material repair

What are the disadvantages of self-healing capacitors

Disadvantages of self-healing capacitors include:

- There are certain disadvantages during operation, which require special design to avoid. In general, the thinner the capacitor’s metallized film, the better its self-healing performance will be. However, the thinner the metallized film, the current carrying capacity of the compensation capacitor will be greatly reduced. In the long run, the capacitor will have the problem of rapid capacity attenuation due to reasons such as excessive operating temperature. Therefore, it is recommended that those self-healing capacitors with thickened metallized film edges be preferred to ensure stable operation of the capacitor in high current or high temperature environments.

- Excessive oil leakage will lead to a decrease in the heat dissipation performance and voltage resistance of the capacitor, and may even affect the normal use of the capacitor.

Self-healing capacitors have high operational reliability and good capacitive performance, which can improve the stability and reliability of the power system, reduce power loss, and improve power supply quality. However, in practical applications, it is necessary to pay attention to its shortcomings and take corresponding measures to avoid them.

What are the advantages of self-healing capacitors

Advantages of self-healing power capacitors include:

- Small size and light weight, saving space and easy to install.

- Large capacity, able to meet the needs of large-capacity compensation.

- High reliability, using self-healing technology, which can ensure that the capacitor automatically repairs faults during operation and improves operational reliability.

- Long life. Due to the use of self-healing technology, the capacitor can withstand multiple overvoltage and overcurrent impacts, thus extending the service life.

- Low maintenance costs. Due to the high reliability of self-healing power capacitors, the frequency of repairs and replacements can be reduced, thereby reducing maintenance costs.

- The reactive power compensation effect is good, which can increase the power factor, improve voltage quality, and reduce line losses and transformer losses.

Self-healing power capacitor is a high-performance, high-reliability power electronic component with wide application prospects in power systems.

What are the advantages of self-healing capacitors compared with ordinary capacitors

The main advantage of self-healing power capacitors over ordinary power capacitors lies in their self-healing function. When the capacitor is impacted by an external voltage that is too high or too low, the self-healing power capacitor can repair itself and return to normal working condition.

This self-healing ability is achieved by the self-healing material inside the capacitor.

Once the capacitor suffers a voltage shock, the self-healing material can quickly fill the insulation defects in the capacitor and prevent the current from continuing to flow, thereby avoiding damage to the capacitor.

This self-healing function makes self-healing capacitors extremely reliable and stable in high-voltage applications and complex circuits, and can maintain stable performance during long-term operation.

In contrast, ordinary power capacitors do not have a self-healing function. Once the insulation is damaged, they need to be replaced or repaired, so their reliability and stability are relatively low.

Self-healing power capacitors also have a longer service life, which can reduce the frequency of replacement and maintenance and reduce maintenance costs.

In addition, self-healing power capacitors have relatively small losses and will not be damaged by multiple overvoltage and overcurrent impacts, so their operation stability and reliability are higher.

Self-healing power capacitors have higher performance and reliability than ordinary power capacitors, which can ensure the stable operation of the power system and reduce losses and maintenance costs.

Under what circumstances should self-healing power capacitors be used

It is recommended to use self-healing power capacitors under the following circumstances:

- It is necessary to improve the power factor of the power system, improve voltage quality, and reduce line losses and transformer losses.

- Situations where harmonics and clutter signals in the power system need to be suppressed to ensure power quality.

- Where it is necessary to operate in harsh environments such as high temperature and high humidity for a long time.

- Situations where the reliability and stability of capacitors are required and stable performance needs to be maintained for a long time.

Under the above circumstances, it is recommended to choose self-healing power capacitors to improve the stability and reliability of the power system and reduce losses and maintenance costs.

What models are there of self-healing power capacitors

There are many types of self-healing power capacitors, some common ones include:

- BZMJ series self-healing low-voltage shunt capacitors: This series of capacitors are suitable for AC power systems with a frequency of 50Hz or 60Hz as electrical equipment to increase power factor, improve power quality, and save energy and reduce consumption.

- BSMJ series self-healing low-voltage shunt capacitors: This series of capacitors are made of metallized polypropylene film material, which has self-healing properties and can effectively limit the short-circuit current of internal components.

- BZMJS series self-healing low-voltage shunt capacitors: This series of capacitors is suitable for low-voltage power distribution systems and has the advantages of small size, long life, and strong anti-harmonic ability.

- BKMJ series self-healing high-voltage shunt capacitors: This series of capacitors is suitable for high-voltage power systems and can provide large-capacity reactive power compensation, increase power factor and improve power quality.

In addition, there are some other models of self-healing power capacitors, such as BSMJX series, BCSMJ series, etc. Different types of self-healing power capacitors have different characteristics and usage occasions, and should be selected according to specific needs.

What is the price range of self-healing capacitors in China

The price of self-healing capacitors varies depending on factors such as model, specification, brand, and there is no unified standard. Generally speaking, the price of self-healing capacitors ranges from tens to hundreds of yuan.

Take some common self-healing capacitor models as examples, such as:

- Chint Capacitor BZMJ 0.45 reactive power compensation self-healing low-voltage parallel power compensator BSMJ three-phase price is 68.83 yuan;

- The price of Hangzhou Chint Power Transmission and Distribution Equipment Co., Ltd.’s Chint capacitor BZMJ0.45-15-3 is 55.44 yuan;

- The price of TENGEN Tianzheng BSMJ-0.45 three-phase self-healing low-voltage reactive power compensation parallel power capacitor 450V is 45.49 yuan;

- The price of ASMJ self-healing AC filter capacitor 10UF from Zhejiang Yueqing Lechuan Electric Co., Ltd. is 23 yuan;

- The price of Anhui Saifu Capacitor Co., Ltd.’s CBB61 self-healing capacitor 10UF is 3.33 yuan.

What is the price range of self-healing capacitors in the United States

In the United States, the prices of self-healing capacitors also vary greatly, and there is no unified standard. Generally speaking, the price range of self-healing capacitors ranges from tens to hundreds of dollars.

It should be noted that these prices are for reference only, and actual prices may vary due to market supply and demand, purchase volume, promotions and other factors. When choosing a self-healing capacitor, you should comprehensively consider its performance, quality, price and other factors to choose the product with the best price/performance ratio.

Is there a problem with the slightly bulging shell of the self-healing capacitor

Even if the self-healing capacitor shell bulges slightly, it indicates that there may be a problem with the capacitor. It is best to investigate the cause immediately, observe the operating status of the capacitor at all times, and replace it in time.

What are the consequences of a bulging capacitor

- Reduce capacitor performance

If a self-healing power capacitor bulges, it means that its internal components are damaged or failed, which will not only cause the capacitance value to decay, but also cause the capacitor’s performance to decline.

- Causing other problems

Bulging capacitors will cause other capacitors to malfunction, and the failure rate will also be greatly increased. If not replaced in time, bulging capacitors may cause short circuits, explosions and other dangerous situations, which in serious cases will pose a serious threat to the company’s economic losses and the personal safety of staff.

Causes of capacitor bulge

- Long-term over-voltage and over-current operation of self-healing capacitors will cause the temperature of the capacitor to rise seriously, the pressure difference between the inside and outside of the casing to be large, and then the capacitor will suffer from bulging failure.

- Factors such as excessive operating environment temperature will also cause the capacitor dielectric to age and internal components to fail. These failures will cause gas or expanding substances to be produced inside the power capacitor, causing the outer casing to bulge.

How to avoid capacitor bulge failure

- Choose high-quality capacitors: When purchasing, you should choose better-quality self-healing capacitor products provided by big brands, which can ensure the reliability of capacitor quality and performance to a certain extent.

- Use capacitors correctly: The operating temperature and operating voltage of self-healing power capacitors should not exceed the specified range to avoid over-voltage or over-current conditions; daily use and operation must comply with relevant guidelines.

- Regular inspection and maintenance: Regularly check the status of the capacitor, including appearance, bulging, and monitoring of capacitor performance. Once a capacitor is found to have bulges or other abnormalities, it should be stopped immediately and repaired or replaced.

- Ensure good ventilation and heat dissipation: Reasonable heat dissipation and ventilation should be considered when the capacitor is running to avoid over-temperature operation.

What are the application scenarios of self-healing capacitors

Self-healing capacitors are widely used in various scenarios of power systems, mainly including the following aspects:

- Power system reactive power compensation: Self-healing power capacitors can provide large-capacity reactive power compensation, improve the power factor of the power system, improve voltage quality, and reduce line losses and transformer losses.

- Harmonic suppression: Self-healing power capacitors have a filtering function and can effectively absorb harmonics and clutter signals in the power system to ensure power quality.

- In the industrial field, self-healing power capacitors can be used for speed control of motors, filtering and power factor correction of power electronic equipment, etc.

- In the field of information technology, self-healing power capacitors can be used in equipment such as data centers and communication base stations to improve their stability and reliability.

- In AC power supply, self-healing power capacitors can be used to absorb various noises and interferences to ensure the DC stability of the power supply output.

Self-healing power capacitors are widely used in various fields of power systems, which can improve the stability and reliability of the system, reduce losses, and improve the quality of power supply.

The top 4 well-known self-healing power capacitor manufacturers in the world

Which of the world’s well-known self-healing power capacitor manufacturers are recommended? The world’s most well-known self-healing power capacitor manufacturers include:

- Germany’s EPCOS/EPCOS AG: It is a world-famous capacitor manufacturer. Its products include electrolytic capacitors, capacitor components, inductors, ceramic capacitors, etc., which are widely used in communications, consumer electronics, industrial automation, and automotive electronics. and other fields.

- VISHAY/VISHAY Intertechnology of the United States: It is one of the world’s largest passive component manufacturers. Its products include resistors, capacitors, inductors, etc., which are widely used in automobiles, industry, medical, communications and other fields.

- Japan’s Panasonic/Panasonic Corporation: It is a world-renowned manufacturer of electronic products. Its products include capacitors, batteries, electronic components, etc., which are widely used in home appliances, automobiles, industry and other fields.

- Samsung/Samsung Electronics of South Korea: It is a world-renowned manufacturer of electronic products. Its products include smartphones, TVs, refrigerators, washing machines, etc. It also produces various electronic components, of which capacitors are one of the important products.

In addition, there are some well-known domestic self-healing power capacitor manufacturers, such as Huawei Electric, Jianghai Co., Ltd., etc.

These manufacturers have high reputation and market share, and their products have certain guarantees in terms of performance, quality, reliability, etc. When selecting a self-healing power capacitor manufacturer, comparison and selection should be made based on specific needs.