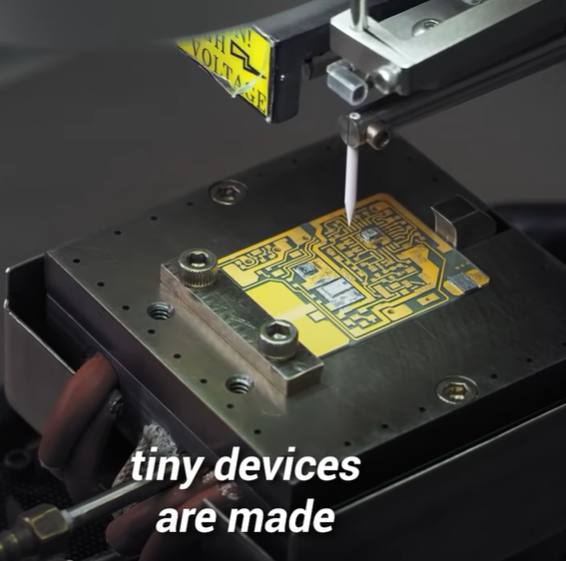

Component aging test methods and standards are important means to evaluate the reliability of components.

They are designed to test the performance of components in harsh environments by simulating various stress factors under actual working conditions.

Standards vary by product and application, and test time, conditions, and methods need to be strictly controlled to avoid damage to components.

Methods to evaluate the aging effect include visual inspection, performance testing and life testing.

The purpose of component aging test

Component aging test is a method to evaluate the performance stability and reliability of components under specified conditions.

Through aging tests, potential early failures or performance degradation problems can be discovered and eliminated, ensuring that components can operate reliably under normal working conditions.

Classification of aging tests

- Natural aging: During the product life cycle, let the components run naturally for a period of time in the actual working environment to observe their performance changes and failure modes. This method is often used to evaluate the long-term reliability of components.

- Accelerated aging: Accelerate the aging process of components by applying stress that exceeds normal working conditions. Commonly used accelerated aging conditions include high temperature, high humidity, high voltage, high current, etc. Accelerated aging is often used to shorten evaluation cycles and quickly identify potential problems.

Aging test method

- Constant stress method: Under certain stress conditions, a batch of components are aged for a long time to observe their failure time. This method is suitable for situations where it is known that stress has a greater impact on components.

- Step stress method: Gradually increase the stress until the component fails, and record the failure time at each stress level. This approach provides a more complete understanding of component performance under different stress conditions.

- Sequential stress method: Aging is performed at multiple different stress levels, each stress level is maintained for a certain period of time, and then transferred to the next stress level. This method can simultaneously examine the effects of multiple stress factors on components.

Standards for aging tests

- Environmental conditions: According to the characteristics and application scenarios of the components, select appropriate environmental conditions such as temperature, humidity, air pressure, etc. for aging.

- Test samples: Select a certain number of components as test samples, and determine the number of samples according to the test purpose and test cycle.

- Failure criteria: Clarify the failure criteria of components, such as performance degradation, parameter drift, open circuit, short circuit, etc.

- Data analysis: Perform statistical analysis on test data, calculate the life distribution, failure rate and other indicators of components, and evaluate their reliability.

- Report writing: Write a test report according to the prescribed format, including test purpose, sample information, test conditions, data analysis, conclusions, etc.

Analysis of common failure modes

During component aging testing, common failure modes include:

- Performance degradation: The performance parameters of components gradually deviate from the normal range, which may lead to abnormal circuit function.

- Fatigue failure: Due to the repeated action of mechanical stress or electrical stress, the internal structure of the component undergoes fatigue damage, eventually leading to fracture or fatigue failure.

- Electromigration: Under the action of electric current, metal ions migrate in semiconductor materials, causing circuit performance degradation.

- Thermal failure: component performance degradation or failure caused by overheating.

- Environmental stress corrosion: Under specific environmental conditions (such as moisture, salt spray, etc.), components are corroded and fail.

For these failure modes, corresponding measures can be taken to simulate and evaluate during the aging test so that problems can be discovered and solved in a timely manner.

The significance of aging test

Through the component aging test, the following significance can be obtained:

- Improve product quality: Screen out early failure components through aging tests, reduce the failure rate of products in use, and improve overall product quality.

- Shorten the product development cycle: By accelerating the aging of components, potential problems can be discovered and solved as early as possible, thus shortening the product development cycle.

- Reduce maintenance costs: By conducting aging tests on components, potential problems can be discovered before the product is put into use, thus avoiding the costs of later maintenance and replacement.

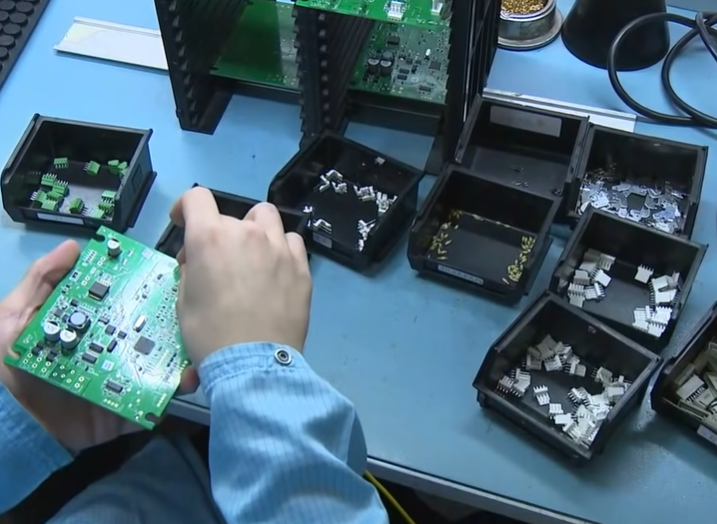

- Improve production efficiency: Through batch aging tests, qualified components can be quickly screened out on the production line to improve production efficiency.

- Ensure product reliability: Through strict aging tests on components, we ensure that products can operate stably and reliably under various working conditions and improve customer satisfaction.

The above content is for reference only. If you need more detailed information, please refer to the international standards or industry specifications related to component aging tests.

Frequently Asked Questions

The component aging test is a reliability test that aims to check whether the components can work normally under various harsh conditions by simulating the stress conditions that the components may encounter in actual work.

The purpose of the aging test is to detect the reliability of components, improve product stability and reliability, and reduce the risk of product failure caused by component failure.

Aging test methods include high-temperature aging, low-temperature aging, humidity aging, vibration aging, impact aging, etc.

The standards for aging tests are usually formulated based on different product standards and industry standards. For example, MIL-STD-2000 is the reliability test standard for U.S. military electronic equipment, and GJB150 is the environmental test method standard for my country’s military equipment.

The timing of the aging test varies with different products and applications and needs to be determined according to specific standards and requirements. Generally speaking, the longer the aging test, the more stringent the reliability testing of components.

The aging test will produce certain stress effects on components, such as high temperature, low temperature, humidity, vibration, impact, etc. These stresses may cause changes in the physical and chemical properties of components, affecting their performance and reliability. Therefore, the test conditions and time need to be strictly controlled during the aging test to ensure that no excessive damage is caused to the components.

Evaluating the aging effect of components can be achieved through a variety of methods, such as appearance inspection, performance testing, life testing, etc. These methods can help us understand the performance of components in aging tests to determine their reliability and stability.