The difference between PLC transistor output and relay output

The difference between PLC transistor output and relay output is that transistor output has the characteristics of fast response, low energy consumption, high safety and high stability, and is suitable for occasions requiring high-precision control and fast response; while relay output has strong load capacity and is used It has the advantages of long life and low cost, and is suitable for situations where larger loads need to be driven.

What is plc transistor output?

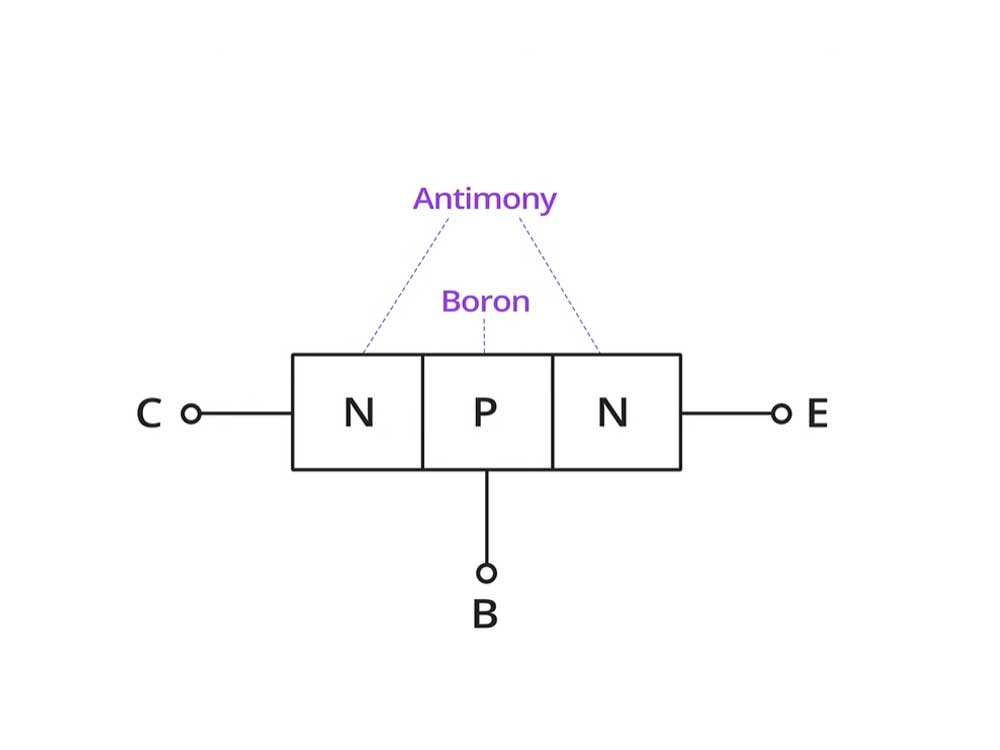

PLC transistor output is an output method that achieves output control by controlling the on and off of the transistor. When the PLC’s output signal is activated, the transistor is turned on, allowing current to flow; conversely, when the signal is not activated, the transistor is turned off and current cannot pass. This output method is mainly used in situations where fast response and high stability are required.

Compared with relay output, transistor output has faster response speed and higher stability. Because the transistor outputs less current, it does not produce a larger arc like a relay output, thus reducing the risk of fire and electric shock. In addition, the energy consumption of the transistor output is relatively low because it has a small on-resistance and has no mechanical moving parts.

However, there are some limitations to transistor output. For example, it can only drive smaller loads because the transistor’s output current is smaller. In addition, the cost of transistor output is relatively high because its manufacturing process and materials are more complex.

In practical applications, the choice of transistor output or relay output depends on specific needs and scenarios. If you need fast response, high stability, and high safety, you can choose transistor output; if you need to drive a larger load and have a tight budget, you can choose relay output.

What are plc transistors and simulated tubes?

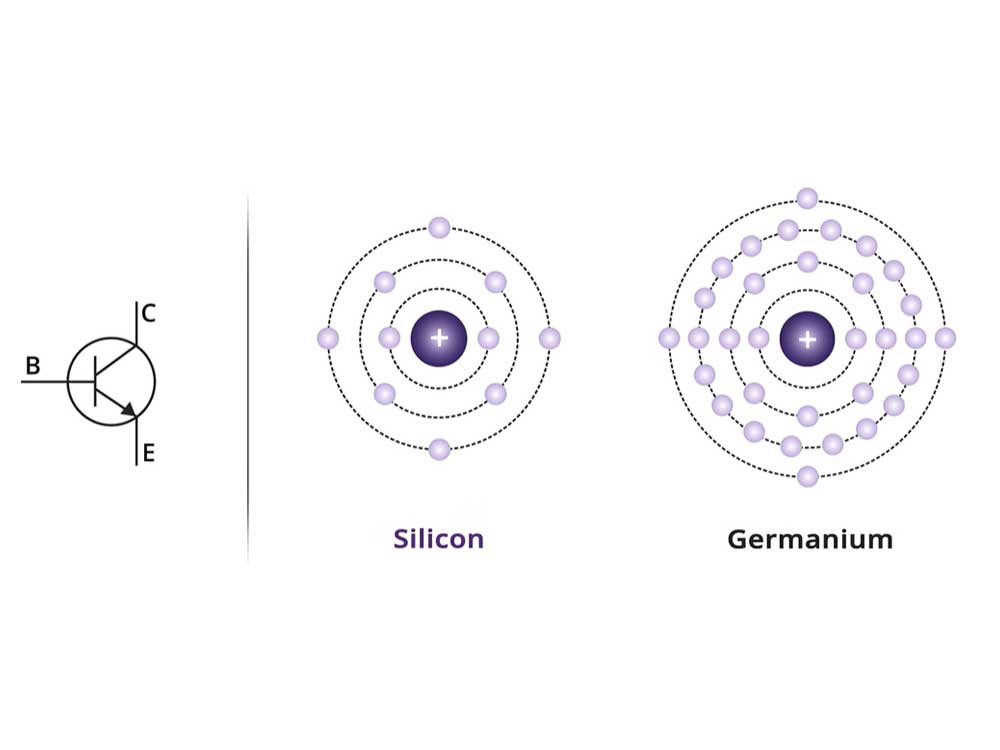

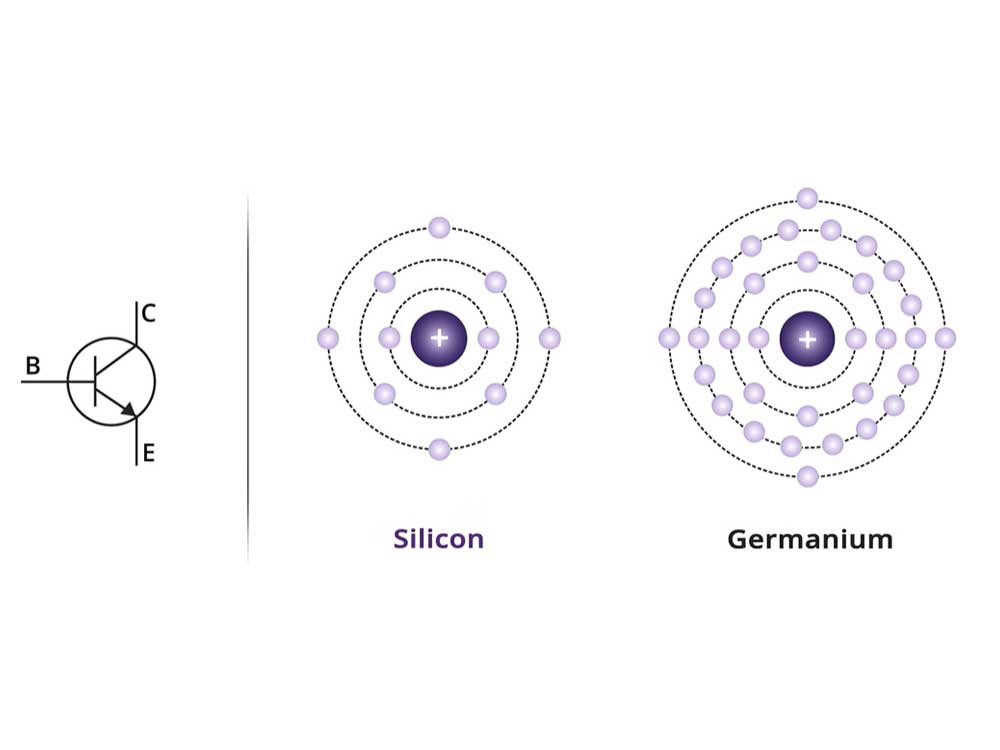

A PLC transistor is a special type of triode used in power line communications (PLC) systems. It is a primary component used to modulate and demodulate power line carrier signals. The structure of PLC transistor is similar to that of ordinary transistor, but it has special structure and materials inside to meet the requirements of high frequency and high voltage.

PLC transistors are optimized to work stably in high-frequency and high-voltage environments. It is commonly used to convert digital signals into power line carrier signals for remote data transmission and control over power lines.

On the other hand, simulation tubes (analog tubes) refer to components used to simulate electronic circuits. It represents signals in a continuous range of current and voltage and can produce a nonlinear response within this range. Simulation tubes generally use multipole effect or corona amplification effect to achieve signal amplification and adjustment. It plays a key role in analog electronic circuits and is often used to amplify, filter, and condition analog signals.

It should be noted that PLC transistors and emulation tubes are two different components used in different application fields. PLC transistors are mainly used in power line communication systems, while simulation tubes are mainly used in analog electronic circuits.

What does PLC relay output mean?

PLC (programmable logic controller) relay output refers to the relay output in the PLC output module. In PLC control systems, relay outputs are usually used to control external devices or perform specific operations.

PLC relay output module usually consists of a set of electromagnetic relays, each relay corresponds to an output point. The PLC controller controls the circuits of external devices by controlling the on and off of these relays. Relay output modules provide reliable switching control for larger loads or applications requiring high voltage or current.

Various control operations can be achieved using PLC relay output, such as switching on and off a device, controlling the start and stop of a motor, triggering an alarm, controlling lights, etc. Through programming, the PLC controller can trigger different output operations based on changes in input signals to achieve automated control and logic control.

In short, PLC relay output refers to the relay output point in the PLC output module, which is used to control the circuit of external equipment and realize control and automation functions.

The difference between PLC transistor output and relay output

Transistor output and relay output of PLC (Programmable Logic Controller) are two common output methods, and there are some differences in performance and application.

The following is a detailed introduction to these two output methods so that you can better understand their characteristics and application scenarios.

transistor output

Transistor output is a common output method of PLC, and its output current is small, usually 20mA or less. Since the current output by the transistor is small, it can only drive smaller loads, such as LED indicators, small solenoid valves, etc. The advantage of transistor output is fast response speed, because the switching speed of transistors is fast and the output signal can be quickly controlled on and off. In addition, the transistor output has strong anti-interference ability and is suitable for noise-sensitive occasions.

Relay output

Relay output is another common PLC output method, which switches signals on and off through mechanical contacts. The relay outputs a larger current and can drive larger loads, such as contactors, motors, etc. The advantage of relay output is that it has strong load capacity and can drive larger currents. In addition, the relay output has a long service life because the mechanical contacts have a relatively long life. However, relay outputs are slower to respond because the mechanical contacts act relatively slowly.

The above introduces the basic concepts and differences between transistor output and relay output. In actual applications, which output method to choose depends on specific needs and scenarios. If you need fast response and strong anti-interference ability, you can choose transistor output; if you need to drive a larger load, you can choose relay output.

Transistor Output Vs Relay Output Characteristics and Applications

In addition to the basic concepts and differences introduced above, transistor outputs and relay outputs have several other features and applications that need to be considered. Here is a more in-depth analysis and comparison of these two output methods:

Energy consumption

Transistor outputs and relay outputs have different energy consumption. Transistor output usually has lower energy consumption because it has lower resistance in the on state, while relay output has a larger contact resistance in the on state, so the energy consumption is relatively higher. Therefore, transistor output is more suitable where the output state needs to be maintained for a long time.

safety

Security is one of the important factors to consider when choosing an output method. Because the transistor output current is smaller, it does not generate a larger arc like a relay output, thereby reducing the risk of fire and electric shock. Therefore, transistor output is more suitable for applications that require high safety, such as medical equipment, food processing equipment, etc.

stability

Stability is one of the important factors to consider when choosing an output method. Since the current output by the transistor is small, it is not easily affected by the external environment, such as temperature, humidity, etc. The stability of the relay output is relatively low because the action speed and life of the mechanical contacts are affected by environmental factors. Therefore, in situations where high stability is required, such as industrial automation control, traffic control, etc., transistor output is more suitable.

Transistor and relay costs

Cost is one of the important factors to consider when choosing an output method. Because the structures and materials of transistor outputs and relay outputs are different, their costs are also different. Generally speaking, the cost of transistor output is higher because its manufacturing process and materials are more complex. The cost of relay output is relatively low because its structure is simple and easy to manufacture. Therefore, in situations where the budget is tight, such as small equipment, household appliances, etc., relay output is more suitable.

In short, choosing transistor output or relay output depends on specific needs and scenarios. Where fast response, high safety, and high stability are required, transistor output can be selected; where larger loads need to be driven and the budget is tight, relay output can be selected.

PLC transistor output or relay output, which one is more energy-saving?

There are certain differences in energy saving between PLC’s transistor output and relay output.

Transistor output uses electronic components for switching and has no mechanical moving parts, so its energy consumption is relatively low. The resistance of a transistor in the on state is small, so its conduction loss is also small. In addition, the transistor output has a fast response speed and can perform switching operations quickly, thereby reducing unnecessary energy consumption.

In contrast, the energy consumption of relay output will be relatively high due to the presence of mechanical moving parts. The relay has a large contact resistance in the conductive state, resulting in a certain amount of energy loss. At the same time, certain mechanical wear and arcing will occur during the operation of the relay, which will also increase energy consumption.

Therefore, from an energy saving perspective, transistor output is more energy efficient than relay output. However, it should be noted that in actual applications, energy-saving performance will also be affected by factors such as specific circuit design and workload. Therefore, when selecting the output type, you need to comprehensively consider the actual needs and system requirements to select the most suitable output method.