The research on electronic components of purifier PCB boards is dedicated to in-depth exploration of the role and working principle of electronic components in purifier PCB boards to improve the performance and stability of purifiers.

Through continuous technological innovation and market research, we continue to promote the progress of the purifier industry and provide users with more efficient and reliable products.

What is a purifier PCB circuit board

Purifier PCB circuit board refers to the PCB board used in purification machines. Its main function is to adsorb, decompose or transform various air pollutants, effectively improving air cleanliness.

Purifier PCB circuit board is an electronic component used in air purifiers. Its function is to control the operation of the air purifier and ensure that it works safely and effectively.

What electronic components does the purifier PCB circuit board consist of

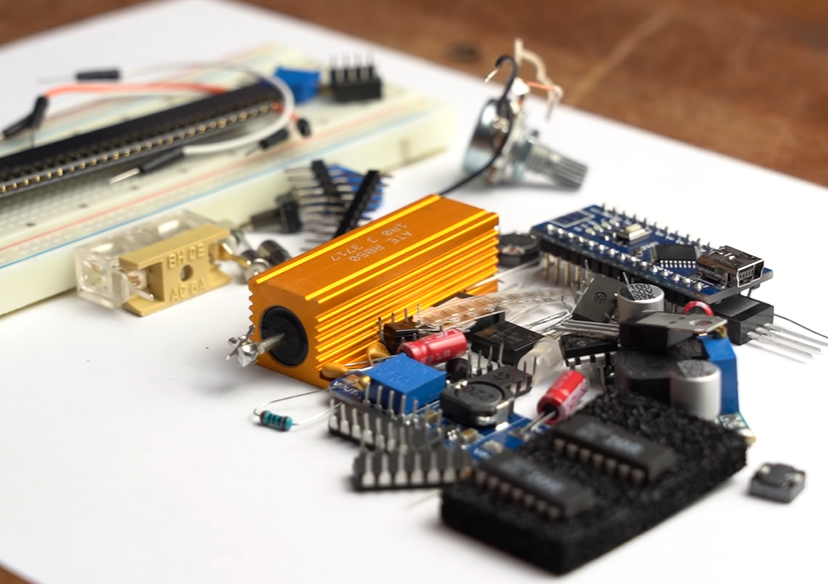

Purifier PCB circuit board usually consists of the following electronic components:

- Microcontroller: used to control and manage various functions and operations of the purifier.

- Sensor: used to detect and monitor pollutant concentration, temperature, humidity and other parameters in the air.

- Driver: used to control the drive circuit of fans, motors or other actuators to achieve functions such as wind speed adjustment and filter replacement of the air purifier.

- Components: including resistors, capacitors, diodes, transistors, integrated circuits, etc.

- Circuit board: composed of pads, vias, mounting holes, wires, components, connectors, fillers, electrical boundaries, etc.

In addition, depending on actual needs, other electronic components may also be included, such as fuses, negative temperature coefficient resistors, common mode chokes, etc. These electronic components cooperate with each other to realize the functions of the purifier PCB circuit board.

How do the components of the purifier PCB circuit board work?

The electronic components on the purifier PCB circuit board cooperate with each other to realize various functions of the purifier.

- As the core control unit, the microcontroller adjusts the speed of the fan or motor through the driver according to the detection results of the sensor to adjust the air flow and purification speed. At the same time, the microcontroller is also responsible for controlling various protection circuits and indication circuits to ensure the safe operation of the purifier and user convenience.

- The sensor is used to monitor parameters such as pollutant concentration, temperature, and humidity in the air, and convert these parameters into electrical signals and transmit them to the microcontroller. The microcontroller determines the pollution of the air based on the received electrical signal and adjusts the output of the driver to achieve automatic control of air purification.

- The driver controls the operation of fans, motors or other actuators according to instructions from the microcontroller. For example, when the air pollution level exceeds the standard, the driver will increase the fan speed to increase the air purification speed; when the air humidity is too high, the driver will activate the dehumidification function to reduce the air humidity.

- Components include resistors, capacitors, diodes, transistors, integrated circuits, etc., which respectively implement the current limiting, filtering, rectification, amplification and other functions of the circuit to ensure the normal operation of the purifier circuit.

- As a carrier to support and connect electronic components, the circuit board provides electrical connections such as wires and connectors to realize signal transmission and control between electronic components.

To sum up, the electronic components on the purifier PCB circuit board cooperate and control each other to complete various functions of the purifier and improve the quality of indoor air.

Which component controls and manages the purifier PCB circuit board?

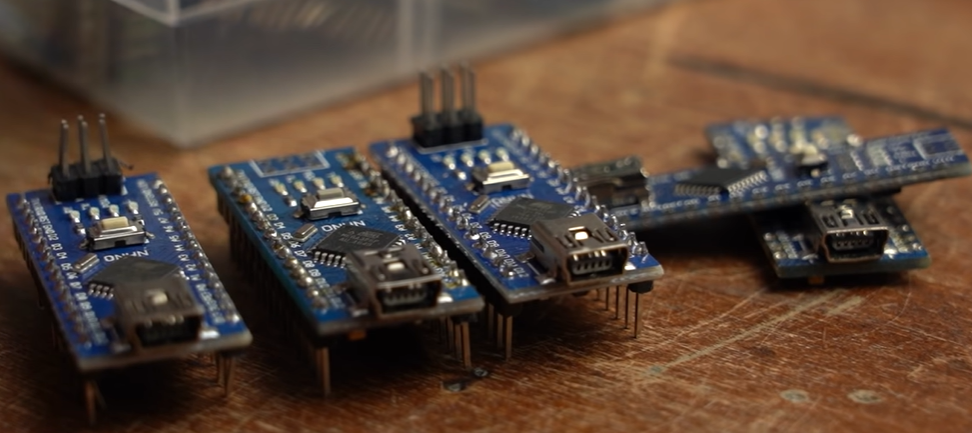

The control and management of the purifier PCB circuit board is mainly responsible for the microcontroller (MCU). The microcontroller is the core control unit of the purifier. It is responsible for receiving and processing the signals input by the sensor. According to the set algorithms and programs, it controls the work of the driver and other actuators to realize various functions of the purifier, such as automatic detection and automatic adjustment. , intelligent control, etc. The microcontroller achieves precise control of the working process of the purifier through programs to ensure the performance and stability of the purifier. At the same time, the microcontroller can also realize communication and control with other smart home devices, making it convenient for users to perform remote control and intelligent management.

Which part of the purifier PCB is the most expensive?

The price of purifier PCB circuit boards varies depending on factors such as manufacturer, quality, function, and material, so it is impossible to generalize which part is the most expensive.

However, generally speaking, as the core control unit of a purifier, the price of a microcontroller is relatively high because it needs to have a high degree of reliability and stability to ensure the normal operation of the purifier.

In addition, components such as sensors and drivers are also relatively expensive parts because they need to accurately detect and regulate various parameters in the air.

Detailed introduction to the purifier PCB circuit board

Purifier PCB circuit board definition

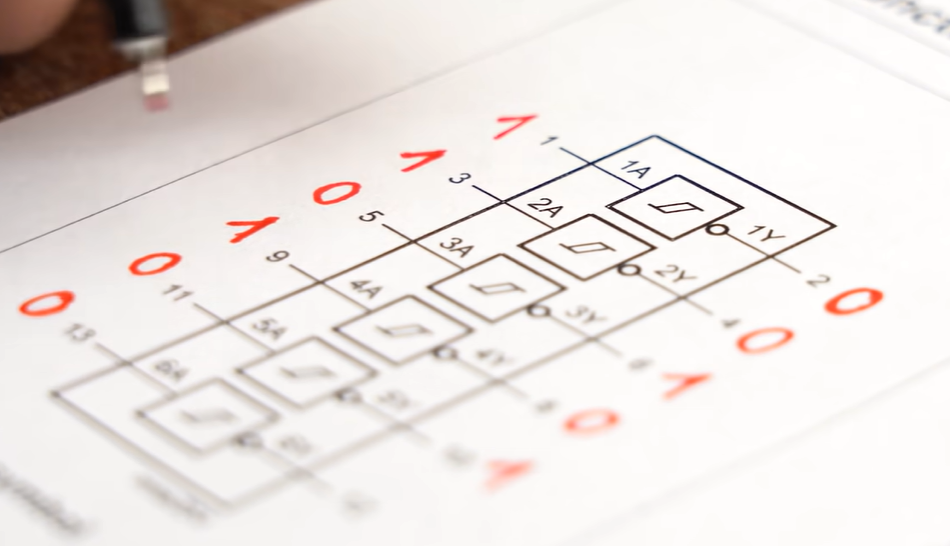

*PCB, which stands for Printed Circuit Board, is an important electronic component. It provides electrical connections between various electronic components in electronic equipment.

PCBs allow electronic components to conductively connect to each other by creating conductive paths on thin sheets of material (such as epoxy, paper phenolic, etc.).

- In air purifiers, the purifier PCB circuit board is the core component specially designed to control the functions of the air purifier. It integrates functional modules such as control, display, sensing and power supply to ensure the normal operation of the purifier.

How does the purifier PCB board work

- The purifier PCB circuit board detects parameters such as air quality and pollutant concentration by receiving signals from sensors.

- Based on these parameters, the purifier PCB circuit board controls the purifier’s operating mode, wind speed and working time.

- It is also responsible for monitoring the status of the purifier, ensuring its normal operation, and providing alarm or shutdown functions when necessary to protect the equipment from damage.

Purifier PCB board components

- Input part: receives external input signals, such as switch control signals, sensor detection signals, etc.

- Processing part: Process the received signal and control the output signal according to the preset program.

- Output part: Control the working status of each component according to the processed signal, such as motor, heating element, indicator light, etc.

- Integrated components: including microcontrollers, transistors, resistors, capacitors and other electronic components, used to realize the logic and computing functions of the circuit.

Purifier PCB circuit board features

- Efficient performance: The purifier PCB circuit board has efficient processing capabilities and can quickly respond to various instructions and sensor signals.

- Strong stability: The circuit board design takes into account long-term operation and high load conditions, and has high stability and reliability.

- Easy to maintain: Designed with repair and replacement needs in mind, the circuit board is easy to disassemble and replace damaged components.

Purifier PCB board application scenarios

- Purifier PCB circuit boards are widely used in various types of air purifiers, such as household, commercial and industrial air purifiers.

- As people’s attention to indoor air quality continues to increase, the demand for purifier PCB circuit boards is also gradually increasing.

Purifier PCB circuit board development trends

- Intelligent: With the development of the Internet of Things and artificial intelligence technology, the purifier PCB circuit board will further realize intelligent functions, such as optimizing the operating mode of the air purifier through artificial intelligence algorithms, and realizing remote monitoring and control.

- Integration: In order to simplify the design and production process of air purifiers, purifier PCB circuit boards may tend to have a higher level of integration, integrating more functions on one circuit board.

- Environmentally friendly materials: With the increase in environmental protection requirements, more environmentally friendly materials may be used in the PCB manufacturing process to reduce the burden on the environment.

Purifier PCB precautions

- When using and maintaining the purifier, safety operating procedures should be followed to avoid safety accidents such as electric shock due to improper operation.

- Discarded purifier PCB circuit boards should be recycled and processed in accordance with relevant environmental protection regulations to avoid harm to the environment.

As the core component of the air purifier, the purifier PCB circuit board plays an important role in ensuring the normal operation of the air purifier and providing good indoor air quality.

As technology continues to advance and application demands continue to grow, purifier PCB circuit boards will continue to develop and achieve more functions and optimizations.

Purifier PCB circuit board electronic components supplier

Globalbestshopping.com is a distributor, manufacturer, and wholesaler of electronic components in China. Tongsha is also an agent for a major electronic component brand.

Purifier PCB circuit board electronic components supplier is committed to providing high-quality, reliable electronic components to meet customer needs in the field of purifier PCB circuit boards.

We have rich industry experience and a professional technical team to ensure that we provide you with high-quality products and services.