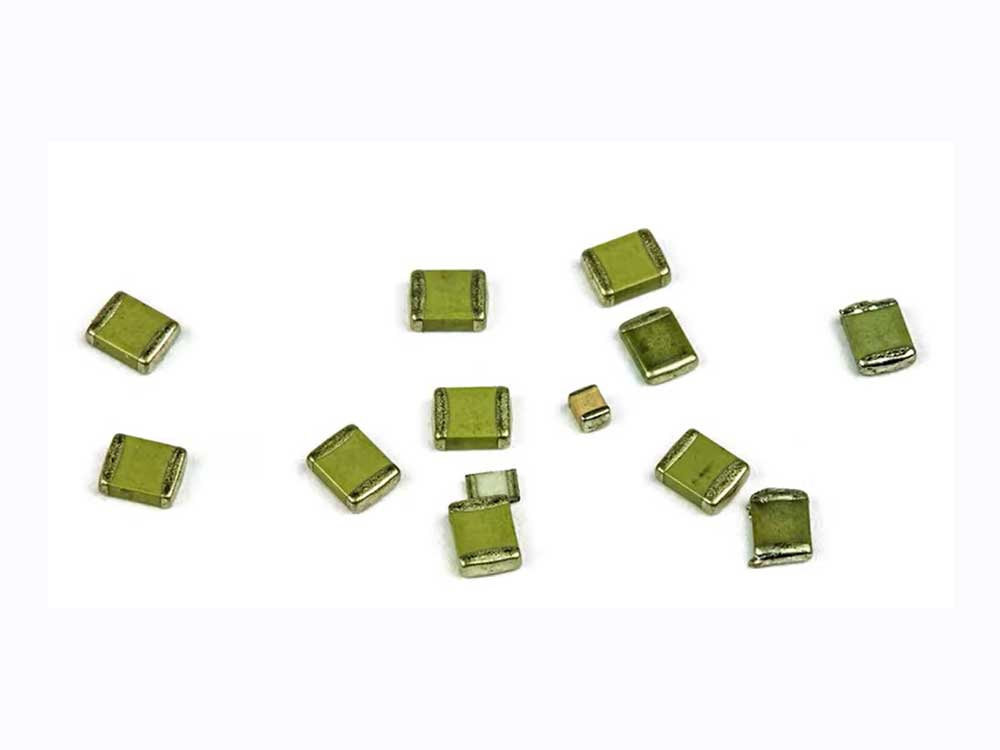

X7R capacitors and X5R capacitors are two common insulation compositions of multilayer ceramic chip capacitors.

X7R and X5R capacitor packaging material characteristics

They have different characteristics:

- X7R capacitor is a strong dielectric, so it can produce capacitors with larger capacity than NPO dielectric.

- X5R capacitors have a high dielectric constant and are often used to produce large-capacity capacitor products with larger specific volumes and higher nominal capacities.

After watching this video you will understand what are the differences between X7R,X8R,X5R,X7S, C0G/COG,NPO Y5V,Z5U capacitors

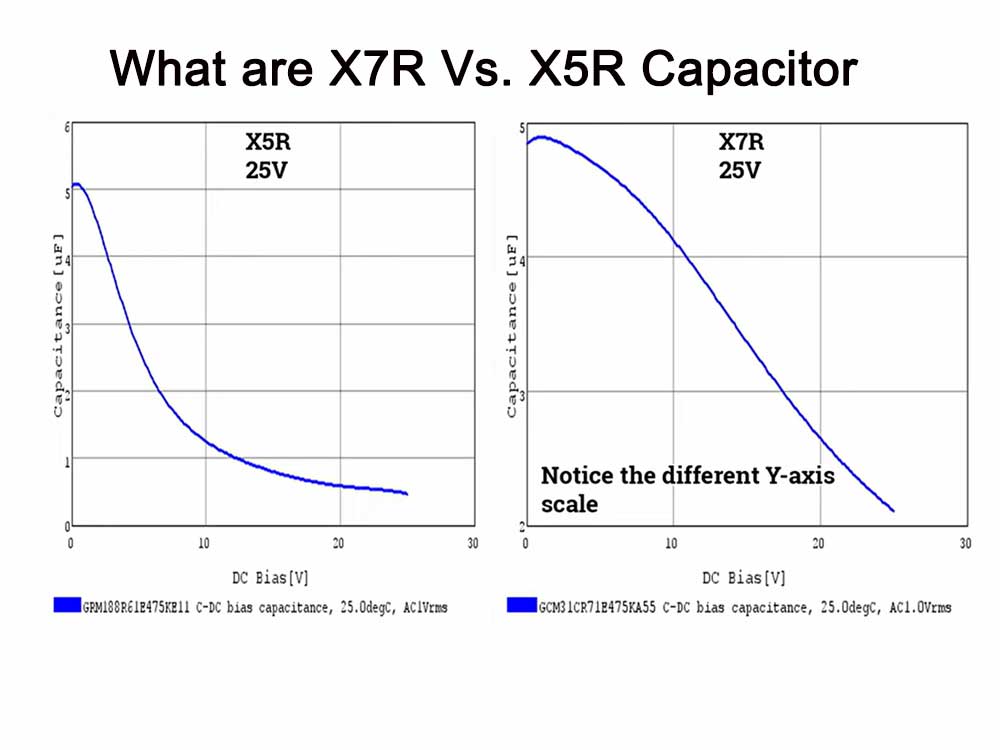

In practical applications, the performance of X7R capacitors and X5R capacitors are also different:

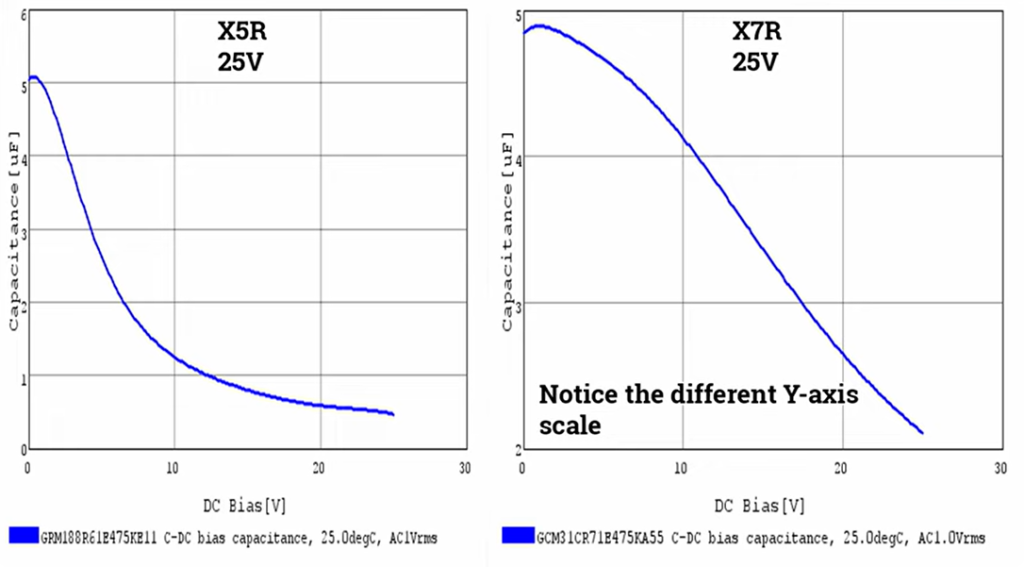

- The performance of X7R capacitors is relatively stable. With changes in temperature, voltage and time, its unique performance does not change significantly. It is a stable capacitor material type and is used in DC blocking, coupling, bypass, filter circuits and applications with high reliability requirements. In medium and high frequency circuits.

- The capacity stability of X5R is slightly inferior to that of X7R. Capacity and loss are more sensitive to test conditions such as temperature and voltage. It is mainly used in oscillation, coupling, filtering and bypass circuits in electronic machines.

In addition, the application temperature range of X7R and X5R is also different. The operating temperature range of X7R is -55℃~+125℃, while the operating temperature range of X5R is -55℃~+85℃.

X7R and X5R packaging materials are widely used in the field of multilayer ceramic chip capacitors. The specific choice of material depends on the actual application requirements.

What are the disadvantages of the X7R and X5R packaging materials

The main disadvantages of X7R and X5R packaging materials are as follows:

- X7R packaging material: Although X7R has a higher dielectric constant and lower dielectric loss, its capacity stability is poor and is easily affected by test conditions such as temperature and voltage. In addition, the X7R also has lower mechanical strength and reliability.

- X5R packaging material: X5R has a low dielectric constant and dielectric loss, so its capacity is small and is not suitable for applications requiring high capacity. In addition, the reliability of the X5R is not as high as that of the X7R.

It should be noted that these shortcomings do not mean that the X7R and X5R packaging materials are not available, but that they still need to be improved in some aspects. In practical applications, appropriate packaging materials can be selected according to specific needs.

What are the application scenarios of X7R and X5R packaging materials

The application scenarios of X7R and X5R packaging materials mainly depend on their performance characteristics.

- X7R packaging material: Because X7R has the advantages of good temperature stability, low dielectric loss, and large capacity, it is suitable for application scenarios that require high temperature changes. In addition, due to its high mechanical strength and reliability, X7R is widely used in various medium and high-frequency circuits in the electronics industry, such as DC blocking, coupling, bypass, filter circuits, etc., especially in some applications with higher reliability requirements. Scenes.

- X5R packaging material: X5R packaging material has a relatively high dielectric constant, so it is often used to produce large-capacity capacitor products with larger specific volume and higher nominal capacity. Because of its good capacity stability and sensitivity to test conditions such as temperature and voltage, it is mainly used in oscillation, coupling, filtering and bypass circuits in electronic machines. X5R packaging materials are more suitable for applications requiring high frequency applications or high capacity requirements.

X7R and X5R packaging materials are widely used in different application scenarios, and the appropriate packaging materials need to be selected according to specific needs.

What are the insulation dielectric constant and dielectric loss of X7R capacitor and X5R capacitor

The specific values of insulation dielectric constant and dielectric loss of X7R and X5R are as follows:

- The insulation dielectric constant of X7R is generally between 10,000 and 20,000, while the dielectric loss is less than 2%.

- The insulation dielectric constant of X5R is generally between 8000 and 15000, and the dielectric loss is less than 3%.

Please note that these values may vary depending on the manufacturer, material composition and manufacturing process. Therefore, when selecting X7R and X5R packaging materials, in addition to paying attention to dielectric constant and dielectric loss, it is also necessary to comprehensively consider their application needs and reliability requirements.

What are the dielectric constants of X7R capacitors and X5R capacitors

The dielectric constants of X7R capacitors and X5R capacitors are 3000 to 6000 and 8000 to 12000 respectively.

Which type of material encapsulates capacitors with better performance

Overall, the X7R capacitor packaging material has better capacitor performance.

- Temperature stability: X7R has better temperature stability and is suitable for high temperature environments.

- Capacity stability: X7R has high capacity stability when temperature and voltage change.

However, there are also opinions that the capacitor performance of X5R is better, and the specific choice of packaging material should be determined based on the actual application requirements.

What are the performance indicators of capacitor X7R and capacitor X5R packaging materials

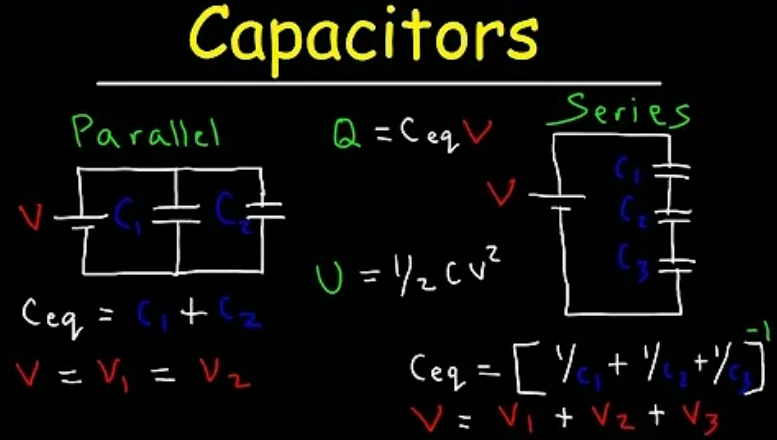

The performance indicators of capacitor X7R and capacitor X5R packaging materials mainly include capacitance, equivalent series resistance (ESR), temperature characteristics, loss tangent value, etc.

- Capacitance: The capacitance ranges of X7R and X5R capacitors are different and need to be selected according to actual needs.

- Equivalent Series Resistance (ESR): This is an important parameter to measure the performance of a capacitor. Lower ESR means better performance.

- Temperature characteristics: The temperature characteristics of X7R and X5R capacitors are different and need to be selected according to actual needs.

- Loss tangent value: This is a parameter that measures the loss of the capacitor. Lower loss tangent value means lower loss.

Generally speaking, the performance indicators of X7R and X5R packaging materials are relatively similar, but the specific values and ranges are different. When selecting packaging materials, these factors need to be considered based on actual needs.

Which one has greater capacity, X5R capacitor or X7R capacitor

Generally speaking, X7R capacitors have larger capacitances and are suitable for applications requiring higher capacitance values. X5R, on the other hand, has a relatively small capacitance and is more suitable for applications with less stringent capacitance value requirements.

However, some people believe that X5R capacitors have a higher dielectric constant and therefore can store more charges. They are often used to produce large-capacity capacitor products with larger specific volumes and higher nominal capacities. The X7R capacitor is a strong dielectric, so it can produce capacitors with a larger capacity than NPO dielectric. This means that X7R capacitors are more suitable in applications requiring high capacitance.

Therefore, the capacity of X5R capacitors and X7R capacitors is not absolute, and the specific selection needs to be determined based on actual application requirements.

Which one is safer, X7R capacitor or X6R capacitor

Both X7R capacitors and X6R capacitors are safer, but which one is safer needs to be considered from different perspectives.

- Considering overload protection: X6R has better overload protection performance and can withstand higher voltage and current. Therefore, X6R may be safer for some application scenarios that need to withstand larger transient currents.

- Considering temperature stability: X7R has better temperature stability and can maintain stable performance in a wider temperature range. Therefore, for some application scenarios that need to work at higher or lower temperatures, X7R may be more suitable. Safety.

To sum up, both X7R and X6R capacitors have high safety. The specific choice of capacitor should be decided based on the actual application requirements. If you need to withstand larger transient currents, you can choose X6R; if you need to work at higher or lower temperatures, you can choose X7R.

What is the difference between the packaging materials of X7R capacitors and X5R capacitors

The main differences between the X7R and X5R packaging materials are their dielectric constant and temperature stability.

- Dielectric constant: X7R has a strong dielectric, while X5R has a higher dielectric constant. This means that X5R can store more charges, so it is often used to produce large-capacity capacitor products with larger specific capacitance and higher nominal capacity.

- Temperature stability: X7R capacitor performance is relatively stable. With changes in temperature, voltage and time, its unique performance does not change significantly. It is a stable capacitor material type and is used in DC isolation, coupling, bypass, filter circuits and reliable In medium and high frequency circuits with higher performance requirements. The capacity stability of X5R is slightly inferior to that of X7R. Capacity and loss are more sensitive to test conditions such as temperature and voltage. It is mainly used in oscillation, coupling, filtering and bypass circuits in electronic machines.

X7R and X5R packaging materials are widely used in the field of multilayer ceramic chip capacitors. The specific choice of material depends on the actual application requirements.

What is the price of packaging materials for Capacitor X7R and Capacitor X5R

The prices of X7R and X5R packaging materials are relatively stable, but are affected by many factors and the specific prices will vary. Generally speaking, the price of X7R packaging materials is relatively high, while the price of X5R packaging materials is relatively low.

The following are factors that may affect the price of X7R and X5R packaging materials:

- Market demand: Market demand is one of the important factors affecting prices. If the market demand is large, the price will rise accordingly; if the market demand is small, the price will fall accordingly.

- Quality: The prices of X7R and X5R packaging materials of different qualities will also be different. High-quality packaging materials usually have higher performance indicators and more stable performance, so the price is relatively high.

- Brand: Well-known brands of X7R and X5R packaging materials usually have higher reputation and quality assurance, so the price is relatively high.

- Supply situation: If the supply of X7R and X5R packaging materials is tight, the price will rise accordingly; if the supply is sufficient, the price will fall accordingly.

To sum up, the prices of X7R and X5R packaging materials are relatively stable, but are affected by many factors. When selecting packaging materials, in addition to considering price factors, it is also necessary to comprehensively consider factors such as performance, quality, brand and supply.

X7R capacitor Vs. X5R capacitor

Application of X7R capacitor and X5R capacitor packaging materials in automotive electronics

Both X7R and X5R packaging materials are used in automotive electronics, but the specific application scenarios are different.

X7R packaging materials are mainly used in power supply, LED, UPS, automotive electronics and other fields. In these fields, high-capacity capacitors are required to provide stable power and signals, as well as high voltage and temperature resistance. The high dielectric constant and stability of the X7R packaging material make it ideal for these applications.

In contrast, X5R packaging materials have relatively few applications in automotive electronics. This is mainly because the X5R packaging material has a low dielectric constant and a small capacity, making it unsuitable for applications requiring high capacity.

To sum up, X7R packaging materials have wider applications in automotive electronics, while X5R packaging materials have relatively few applications. When selecting packaging materials, it is necessary to select the appropriate packaging material based on specific application requirements.