Radio frequency RF circuit design and layout are key links in wireless communication systems. Factors such as impedance matching, electromagnetic compatibility, power control and stability need to be comprehensively considered to ensure signal transmission quality.

The layout must follow the principles of modularity, electromagnetic shielding, power supply and grounding, wiring and heat dissipation design to improve circuit performance and stability. Verify the feasibility and effectiveness of the design through simulation and testing, providing strong support for the development of wireless communication technology.

Radio Frequency RF Circuit Design and Layout Overview

Radio frequency (RF) circuit design is a key link in wireless communication systems, involving many aspects such as the propagation of electromagnetic waves, circuit response characteristics, and material properties.

Layout is an important part of RF circuit design, which affects the performance, stability, reliability and cost of the circuit. When designing and laying out RF circuits, various factors must be fully considered to ensure the feasibility and effectiveness of the design.

Radio frequency RF circuit design principles

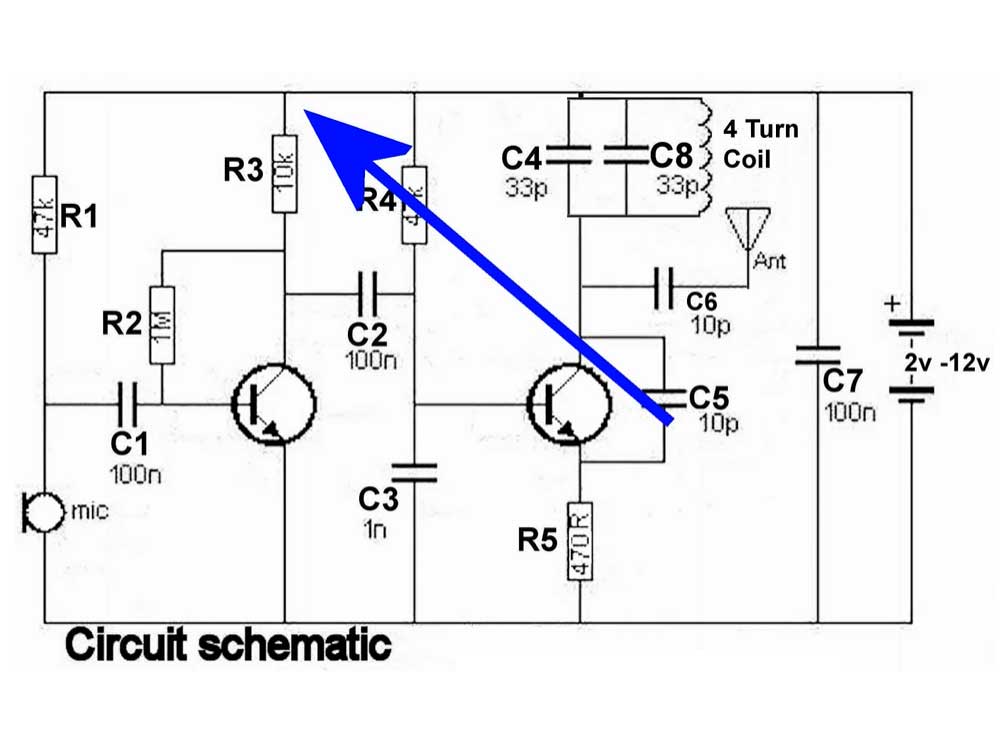

- Impedance matching: In radio frequency circuits, signal transmission is affected by impedance. In order to ensure smooth transmission of signals, impedance matching between the source and load must be achieved. Through reasonable design, making the output impedance of the source equal to the input impedance of the load can effectively reduce signal reflection and loss.

- Electromagnetic compatibility: In radio frequency circuits, the frequency of signals is relatively high, which is prone to electromagnetic interference. Therefore, electromagnetic compatibility issues should be fully considered in the design and effective measures should be taken to reduce interference between different modules.

- Power control: In wireless communications, power consumption is an important consideration. The transmit power should be reasonably controlled to ensure signal coverage and transmission quality, while avoiding interference with other frequency bands.

- Stability considerations: The working environment of radio frequency RF circuits may be complex, and its stability should be fully considered. During design, stable materials and processes should be used to reduce the impact of environmental factors such as temperature, humidity, and pressure on circuit performance.

Radio frequency RF circuit layout principles

- Modular design: Divide the radio frequency RF circuit into different modules, each module is responsible for a specific function. The modular design facilitates maintenance and upgrades and can improve the reliability and stability of the circuit.

- Electromagnetic shielding: During layout, electromagnetic shielding of key components should be considered to reduce the impact of electromagnetic interference on circuit performance. Protecting sensitive components through metal shells, conductive materials, etc. can effectively suppress interference from external electromagnetic waves.

- Power supply and grounding: Reasonable power supply and grounding design are the basis for ensuring the normal operation of radio frequency RF circuits. The stability and reliability of the power supply should be ensured to avoid the impact of power supply fluctuations on circuit performance. At the same time, good grounding can effectively reduce electromagnetic interference and signal leakage.

- Wiring: Wiring is an important link in layout and directly affects the performance of the circuit. The principle of “short, straight and wide” should be followed to reduce loss and reflection during signal transmission. For key signal lines, multi-layer wiring and wire diameter optimization can be used to improve their performance.

- Heat dissipation design: Since radio frequency RF circuits generate a large amount of heat when working, heat dissipation design is crucial. Factors such as heat dissipation paths, heat dissipation materials, and heat dissipation methods should be fully considered to ensure that the temperature of the circuit is stable during operation and to avoid performance degradation or damage due to overheating.

Physical and electrical partitions

In radio frequency RF circuit layout, physical partitioning and electrical partitioning are two important concepts. Physical partitioning mainly involves issues such as the layout, orientation, and shielding of components; electrical partitioning can continue to be decomposed into partitions for power distribution, RF wiring, sensitive circuits and signals, and grounding. Through reasonable physical and electrical partitioning, the performance and stability of the circuit can be improved.

PCB stack design

PCB stack-up design is one of the important factors affecting the performance of radio frequency RF circuits. In the design, the main ground plane (main ground) should be arranged on the second layer under the surface layer, and the RF lines should be arranged on the surface layer as much as possible. This can reduce loss and interference during signal transmission and improve signal quality. In addition, reasonable PCB stacking design can also reduce the thickness and weight of the circuit, which is conducive to achieving thinning and miniaturization requirements.

Simulation and testing

After completing the radio frequency RF circuit design and layout, simulation and testing need to be performed to verify its performance. By using professional simulation software to perform electromagnetic simulation and optimization of the circuit, its performance under different conditions can be predicted. At the same time, actual testing is also a necessary link. Test data can verify the feasibility and effectiveness of the design, and improve and optimize existing problems.

Summary of radio frequency RF circuit design and layout

To sum up, the design and layout of radio frequency RF circuits is a complex and delicate process. In actual work, it is necessary to comprehensively consider multiple factors and conduct comprehensive evaluation and optimization from aspects such as impedance matching, electromagnetic compatibility, power control, and stability. Through continuous improvement and improvement of design and layout solutions, the performance, stability and reliability of radio frequency RF circuits can be improved, providing strong support for the development and application of wireless communication technology.

What factors need to be paid attention to in radio frequency RF circuit design?

In radio frequency RF circuit design, there are several key factors that require special attention:

Signal integrity and power integrity

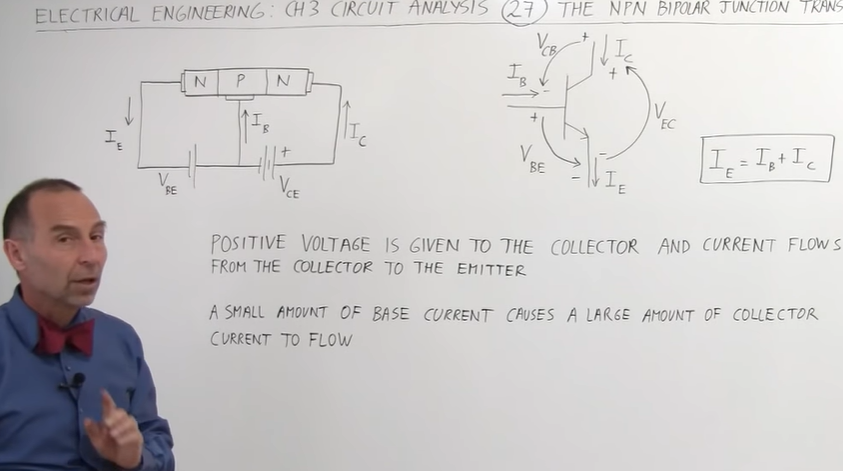

Signal integrity and power integrity are important factors to consider in radio frequency RF circuit design. Signal integrity mainly focuses on the quality of the signal during transmission, including the amplitude, frequency, phase and other characteristics of the signal. Power integrity focuses on power distribution and decoupling issues, including voltage drop, power supply noise, and decoupling capacitor selection.

electromagnetic compatibility

Due to the high operating frequency of radio frequency RF circuits, the problem of electromagnetic interference is more prominent. In the design, a series of measures, such as electromagnetic shielding, filtering, grounding, etc., need to be taken to reduce electromagnetic interference and ensure the stability and reliability of the circuit.

Place and route

Layout and wiring are a very critical part of RF circuit design. Reasonable layout can improve the performance and stability of the circuit while reducing the size and cost of the circuit. When wiring, you need to pay attention to parameters such as the length, width, and spacing of signal lines to reduce loss and interference during signal transmission.

Thermal design

Since RF circuits generate a large amount of heat when operating, thermal design is also a factor that needs to be considered. When designing, factors such as heat dissipation paths, heat dissipation materials, and heat dissipation methods need to be fully considered to ensure that the temperature of the circuit is stable during operation and to avoid performance degradation or damage due to overheating.

Reliability design

Radio frequency RF circuits are usually used in wireless communications, radar, navigation and other fields, and have high requirements for reliability. When designing, it is necessary to consider factors such as the life of components and the impact of the working environment, and take corresponding measures to improve the reliability of the circuit.

In the design of radio frequency RF circuits, the above factors need to be considered comprehensively, and simulation and testing must be performed to verify their performance. Through continuous improvement and design improvement, the performance, stability and reliability of radio frequency RF circuits can be improved, providing strong support for the development and application of wireless communication technology.

How to verify the performance of radio frequency RF circuits?

Verifying the performance of an RF circuit is an important step to ensure that the circuit’s performance meets design requirements. Here are some common verification methods:

- Spectrum analysis: Use a spectrum analyzer to measure the frequency response of a circuit to check for the presence of unwanted frequency components or spurious signals.

- Power test: By measuring the output power of the circuit, verify whether it meets the design requirements. Measurements can be made using devices such as power meters.

- Noise test: Evaluate the noise performance of the circuit, including noise coefficient, signal-to-noise ratio and other parameters. This can be measured using equipment such as a noise analyzer.

- Distortion test: Check the distortion performance of the circuit, such as harmonic distortion, intermodulation distortion, etc. Measurements can be made using equipment such as a distortion analyzer.

- Sensitivity test: Test the receiving sensitivity of the circuit and check the performance of the circuit under low signal strength. Measurements can be made using equipment such as signal generators and spectrum analyzers.

- Phase noise test: Evaluate the phase noise performance of the circuit and check the performance of the circuit at high frequency offset. Measurements can be made using equipment such as a phase noise analyzer.

- Intermodulation test: Check the intermodulation performance of the circuit under different frequency signals. Measurements can be made using equipment such as signal generators and spectrum analyzers.

- Transmission characteristic test: Test the transmission characteristics of the circuit, such as insertion loss, return loss and other parameters. Measurements can be made using equipment such as network analyzers.

- Stability and reliability testing: Test the stability and reliability of the circuit through long-term operation and accelerated life testing.

- Electromagnetic compatibility test: Verify the electromagnetic compatibility of the circuit and check whether it meets the requirements of relevant standards and specifications. You can entrust a professional electromagnetic compatibility testing agency to conduct testing.

In summary, the above methods can help verify the performance of radio frequency RF circuits. In actual testing, appropriate methods can be selected for measurement and analysis based on specific circumstances to ensure that the performance of the circuit meets the design requirements.

How to ensure electromagnetic compatibility in radio frequency RF circuit design?

In radio frequency RF circuit design, electromagnetic compatibility is an important issue. To ensure electromagnetic compatibility, the following measures can be taken:

- Reasonable partitioning: Divide the circuit into different areas according to function, and ensure that high-power RF and low-noise parts are isolated. This reduces the possibility of mutual interference and signal leakage.

- Electromagnetic shielding: Use metal shells or conductive materials to shield key parts to reduce interference from external electromagnetic waves. At the same time, it can also prevent sensitive signals from leaking to the outside.

- Filter design: Add filters at the power input and signal line entrances to reduce the possibility of external interference signals entering the circuit.

- Good grounding: Ensure good and stable grounding, which can effectively reduce electromagnetic interference and signal leakage.

- Wiring strategy: Use short, straight, and wide wiring principles to reduce loss and reflection during signal transmission. For key signal lines, multi-layer boards and optimized wire diameters can be used for wiring.

- Component selection and layout: Select components with low noise and low power consumption, and arrange them reasonably to reduce mutual interference between components.

- Software simulation and testing: Use electromagnetic simulation software to predict and optimize before design, and verify the feasibility and effectiveness of the design in actual testing.

- Comply with standards and specifications: Follow relevant electromagnetic compatibility standards and specifications during the design process to ensure that the design meets industry requirements.

In summary, through measures such as reasonable zoning, electromagnetic shielding, filter design, good grounding, wiring strategies, component selection and layout, software simulation and testing, and compliance with standards and specifications, the electromagnetic compatibility of radio frequency RF circuits can be effectively improved. Ensure its performance is stable and reliable.

What are the principles of radio frequency RF circuit design?

In radio frequency RF circuit design, the following principles need to be followed:

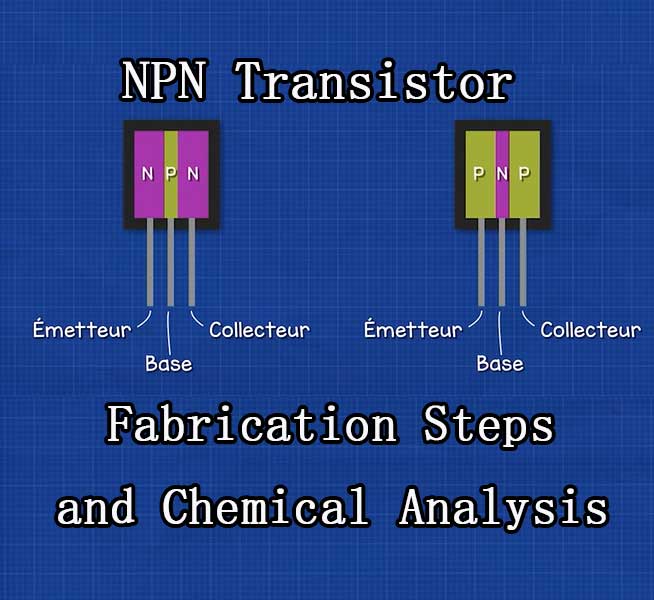

- Isolate the high-power RF amplifier (HPA) and the low-noise amplifier (LNA) as much as possible. Simply put, keep the high-power RF transmit circuit away from the low-power RF receive circuit. This can avoid mutual interference and signal leakage, and improve the performance and stability of the circuit.

- Make sure that the high-power area on the PCB board has at least a whole piece of ground, preferably without via holes. Of course, the larger the copper foil area, the better. This can reduce loss and interference during signal transmission and improve heat dissipation.

- Circuit and power supply decoupling is also extremely important. Through reasonable decoupling design, the impact of power supply fluctuations on circuit performance can be reduced and signal integrity improved.

- The RF output usually needs to be located far away from the RF input. This can avoid signal reflection and mutual interference, and improve the performance and stability of the circuit.

- Sensitive analog signals should be kept as far away from high-speed digital signals and RF signals as possible. This can reduce the interference of digital signals and RF signals on analog signals and improve the performance and stability of the circuit.

- Follow the modular design principle and divide the radio frequency RF circuit into different modules, each module is responsible for a specific function. This can improve the reliability and stability of the circuit and facilitate maintenance and upgrades.

- Consider electromagnetic compatibility and take effective measures to reduce interference between different modules. The impact of electromagnetic interference on circuit performance can be reduced through electromagnetic shielding, filtering, grounding, etc.

- Consider the power supply and grounding design to ensure the stability and reliability of the power supply and avoid the impact of power supply fluctuations on circuit performance. At the same time, good grounding can effectively reduce electromagnetic interference and signal leakage.

- Follow wiring principles, such as “short, straight, wide”, etc., to reduce loss and reflection during signal transmission. For key signal lines, multi-layer wiring and wire diameter optimization can be used to improve their performance.

- Consider thermal design. Since RF circuits generate a large amount of heat when working, factors such as heat dissipation paths, heat dissipation materials, and heat dissipation methods need to be fully considered to ensure that the temperature of the circuit is stable during operation and to avoid performance degradation or overheating. damage.

To sum up, the above principles are the basic requirements that need to be followed in the design of radio frequency RF circuits. By comprehensively considering these factors and continuously optimizing the design, the performance, stability and reliability of radio frequency RF circuits can be improved, providing strong support for the development and application of wireless communication technology.