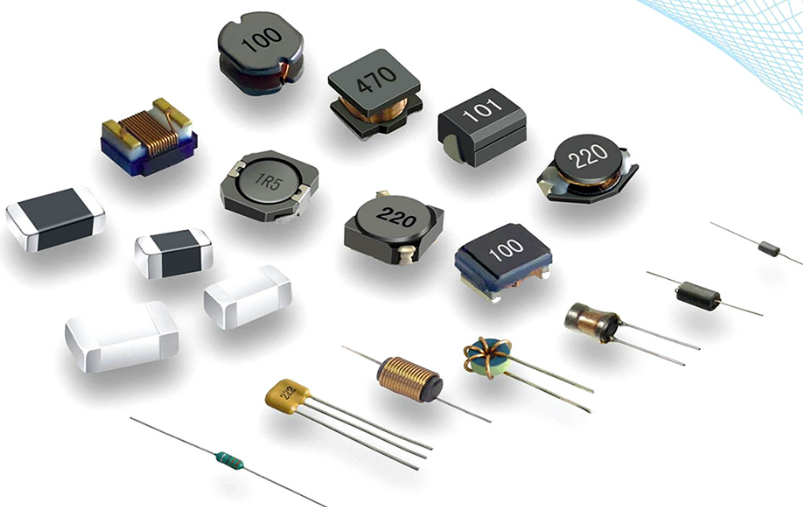

Inductor is one of the very important components in electronic engineering. It has unique functions and properties and is widely used in various electronic equipment and systems.

In this article, we will introduce 10 commonly used inductors and their common functions to help you better understand and apply inductors.

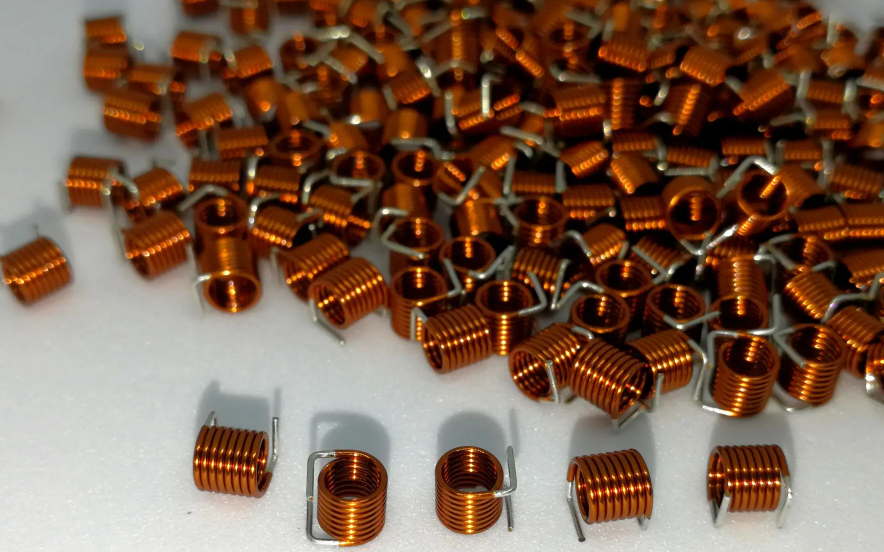

Air core inductor

Air-core inductors are mainly used in induction reception, focusing, magnetic cards, magnetic heads, high current coils, low-voltage electrical appliances, industrial control, household appliances, automotive electronics, SMT mounting, mobile phones, wireless transceivers, electronic navigators, power regulators, amplifiers , suppliers and filtering and other fields.

Air-core inductors are a very common inductor that consists of a coil of wire and are commonly used in applications such as filtering, chokes, and antennas. The advantage of air-core inductors is that they are easy to make and debug, but the disadvantage is that they are larger and are not conducive to miniaturization.

The air-core inductor has a current-blocking effect, and the self-induced electromotive force in the coil always opposes the current changes in the coil. The air-core inductor has a blocking effect on AC current. The magnitude of the blocking effect is called inductive reactance xl, and the unit is ohms. In addition, the air-core inductor also has tuning and frequency selection functions. When the natural oscillation frequency f0 of the circuit is equal to the frequency f of the non-AC signal, the inductive reactance and capacitive reactance of the loop are also equal, so the electromagnetic energy oscillates back and forth between the inductor and the capacitor. , this is the resonance phenomenon of the LC circuit.

Ferrite inductor

Ferrite inductor is an inductor made of ferrite material. It has the advantages of high magnetic permeability and low loss, so it is often used in high-frequency circuits. The disadvantage of ferrite inductors is that they are large and difficult to miniaturize.

Ferrite inductor is a special kind of inductor, which consists of ferrite core and wire. Ferrite is a magnetic material sintered from a combination of magnetic powders with different characteristics and has high magnetic permeability.

The special characteristics of ferrite inductors depend on the material composition of the ferrite core. Ferrite materials are usually used at high frequencies because they are mainly inductive at low frequencies, making the loss on the line very small. At high frequencies, the characteristic is mainly reactive and changes with frequency.

In practical applications, ferrite materials are used as high-frequency attenuators in radio frequency circuits. In fact, ferrite is better equivalent to a parallel connection of a resistor and an inductor. At low frequencies, the resistor is short-circuited by the inductor. At high frequencies, the impedance of the inductor becomes quite high, so that all current passes through the resistor.

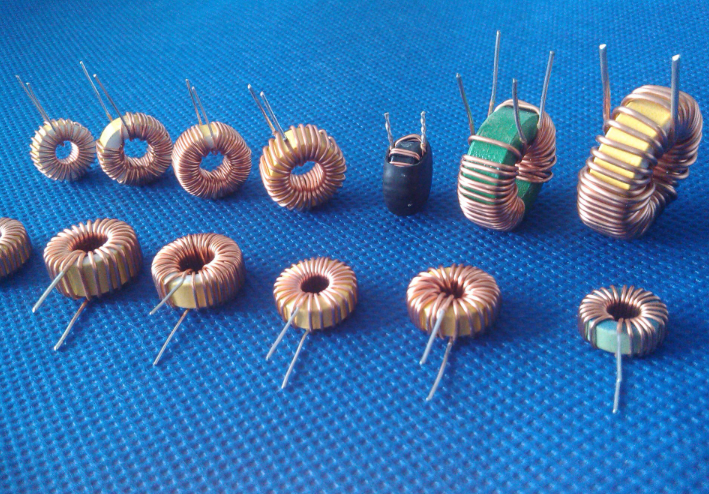

Wirewound inductor

Wirewound inductor is an inductor made by winding wire around a bobbin. It has the advantages of high magnetic permeability and low loss, and can also achieve miniaturization and high precision. Wirewound inductors are commonly used in precision measurement and oscillator circuits.

A wirewound inductor is a common inductor that consists of wire wound around a magnetic core. The characteristics of a wirewound inductor depend on factors such as the number of turns in its coil, the material and shape of the core, and the operating frequency.

The main function of a wire-wound inductor is to store electrical energy and filter. It can produce inductive reactance to AC current, thereby limiting the amplitude and frequency changes of the current. In power supply circuits, wirewound inductors are often used to filter out high-frequency noise and stabilize current.

The advantage of wire-wound inductors is that they have higher inductance and current capacity, and can withstand larger current impacts. In addition, wirewound inductors have a simple structure and are easy to manufacture and debug.

It should be noted that the quality factor (Q value) and equivalent series resistance (ESR) of the wirewound inductor are important parameters that affect its performance. The higher the quality factor, the smaller the loss of the inductor and the higher the efficiency; the larger the equivalent series resistance, the greater the internal resistance of the inductor, and the greater the impact on the circuit.

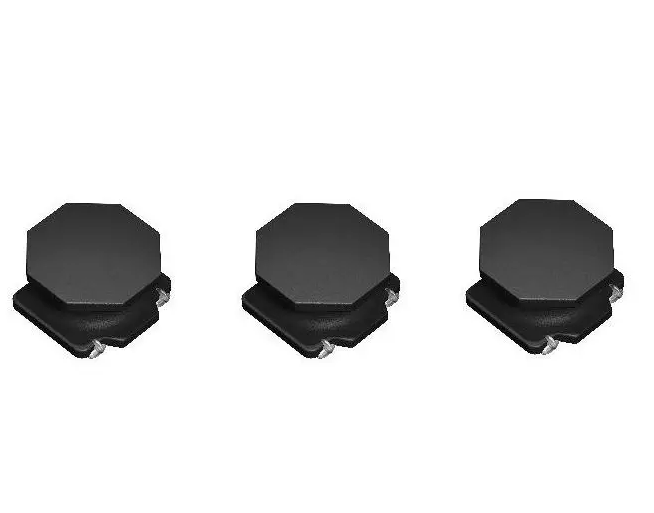

Multilayer inductor

A laminated inductor is an inductor made by laminating a coil and a magnetic core. It has the advantages of high magnetic permeability, low loss and miniaturization. Multilayer inductors are commonly used in radio frequency circuits and portable devices.

Multilayer inductor is a non-wound inductor, which is one of the types of inductors classified according to different structures. It has the characteristics of small size, no interactive interference in a closed circuit, no directionality, excellent solderability and solder resistance, and is suitable for high-density installation and standardized automatic patch installation.

The laminated inductor has better heat dissipation and smaller ESR value, but its current resistance is smaller than that of winding. In comparison, the heat dissipation of wire winding is not as good as that of lamination, and the ESR value is higher, but the current resistance will be greater. Additionally, lamination costs less than wire wrapping.

In practical applications, laminated inductors can be used instead of wire-wound inductors, but the following points need to be noted: First, the parameters of laminated inductors are better and higher than those of wire-wound inductors; second, attention should be paid to the differences between laminated inductors and winding inductors. Differences in line inductances, such as their heat dissipation and current resistance capabilities.

Thin film inductor

Thin film inductor is an inductor made using thin film technology. It has the advantages of high magnetic permeability, low loss and miniaturization. Thin film inductors are commonly used in microwave and radio frequency circuits.

Thin film inductor is an inductor made using vacuum thin film technology. It has the advantages of high reliability, easy integration and chip formation, very suitable for automated surface mount technology (SMT), small size, and good high-frequency characteristics. It has been It has become a hot spot of research at home and abroad.

Power inductor

Power inductor is an inductor used in power circuits, which usually has large current capacity and high thermal performance. Power inductors are commonly used in applications such as power supply filtering, energy storage, and load matching.

Power inductors, also known as high current inductors and surface mount high power inductors, have the characteristics of miniaturization, high quality, high energy storage and low resistance. It is mainly used to generate alternating magnetic flux in and around the conductor when AC current passes through it.

magnetic beads

Magnetic beads are an inductor made of magnetic materials. They have the advantages of high magnetic permeability, low loss and miniaturization. Magnetic beads are commonly used in electromagnetic interference suppression and filtering applications.

Magnetic beads are a passive component mainly used to suppress high-frequency noise and spike interference in circuits. It uses heat dissipation generated by high-frequency current to suppress high-frequency noise. The components of magnetic beads are mostly ferrite, which has high resistivity and magnetic permeability. They are connected in series on signal or power paths to suppress high-frequency noise.

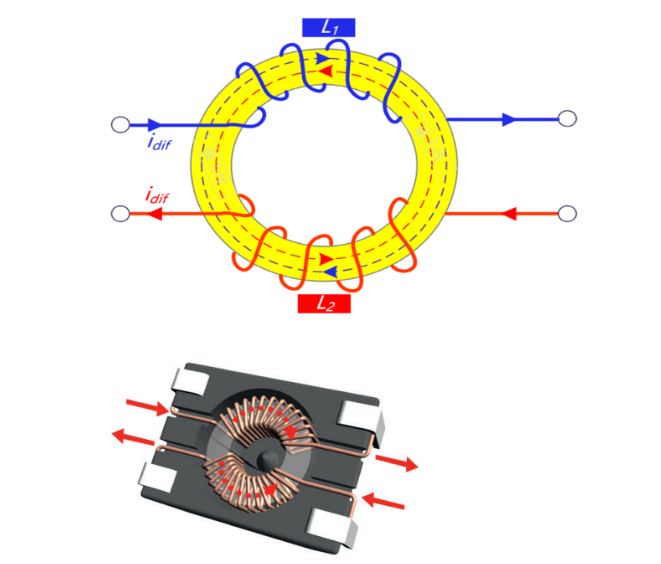

Common mode inductor

Common mode inductor is an inductor used to suppress common mode interference. It usually consists of two coils and can effectively suppress common mode noise. Common mode inductors are commonly used in digital and analog circuits.

Common mode inductors are often used in computer switching power supplies to filter common mode electromagnetic interference signals. In the board design, the common mode inductor also plays the role of EMI filtering, which is used to suppress the outward radiation and emission of electromagnetic waves generated by high-speed signal lines. The common mode inductor is essentially a two-way filter: on the one hand, it must filter out common mode electromagnetic interference on the signal line; on the other hand, it must suppress itself from emitting electromagnetic interference to avoid affecting the normal operation of other electronic equipment in the same electromagnetic environment. .

Differential inductance

Differential inductor is an inductor used for differential signal transmission. It usually consists of two coils and can effectively suppress noise and interference. Differential inductors are commonly used in high-speed digital signal transmission and radio frequency communications.

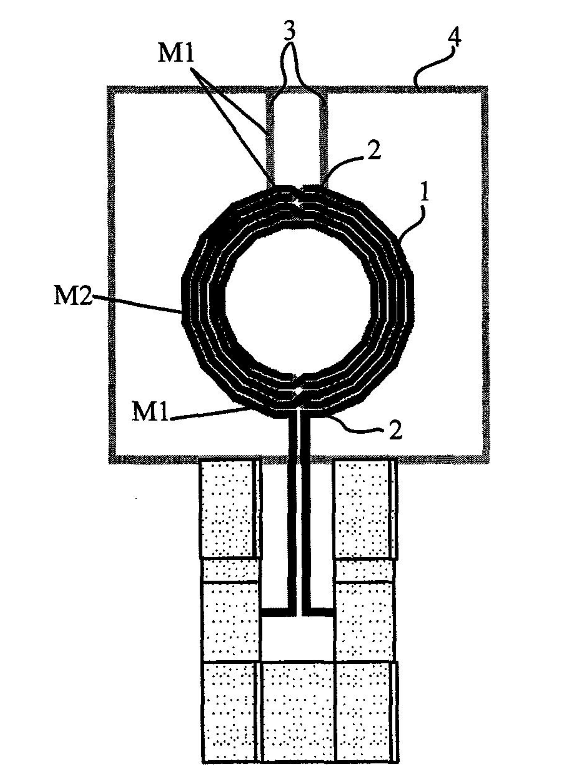

variable inductor

A variable inductor is an inductor that can change its inductance as needed. It usually consists of a coil and a variable magnetic core, and can be continuously adjusted within a certain range. Variable inductors are commonly used in tuned circuits and automatic control systems.

The variable inductor is a variable inductor with a saturable magnetic core. The magnetic core has three core legs (42, 43, 44), including a central core leg (43) and two outer core legs. Iron core column. Two parallel-connected outer coils (46, 47) are wound around the outer core leg. By controlling the current of the coil, the saturation of the outer iron core leg can be changed, thereby changing the inductance of the inductor.

In short, the above are 10 commonly used inductors and their common functions. I hope it can help you better understand and apply inductors. In your future electronic engineering study and practice, I believe you will be more proficient in using this knowledge!