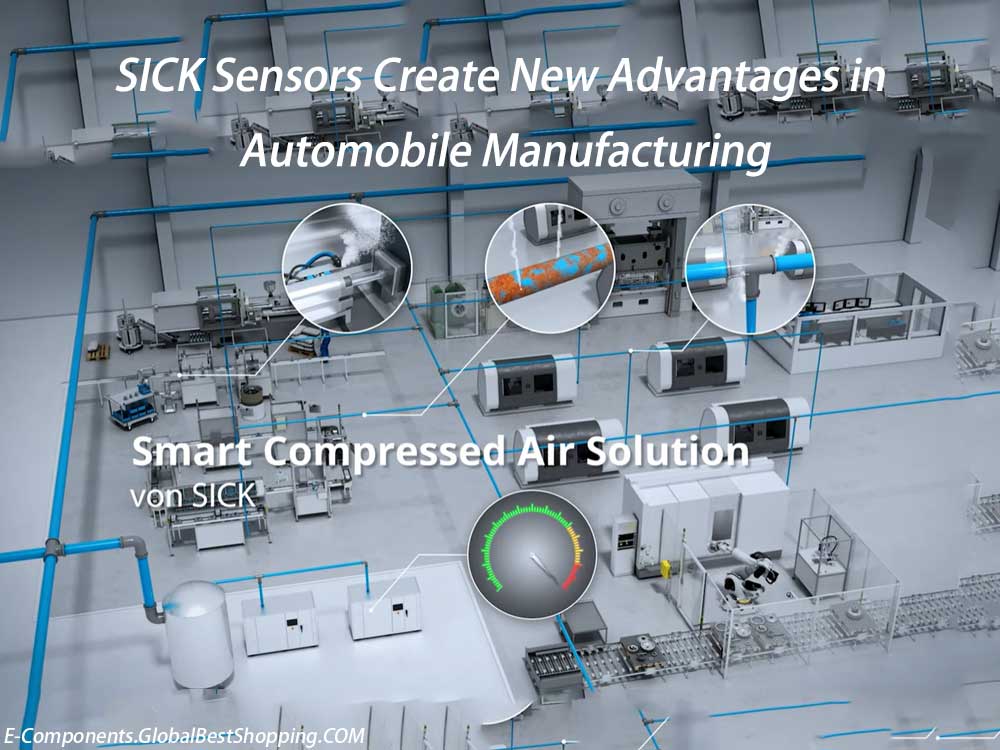

SICK sensors, as a leader in the field of industrial automation, have been widely and deeply applied in the field of automobile manufacturing, bringing significant new advantages to the automobile manufacturing industry.

The following will introduce in detail how SICK sensors create new advantages in automobile manufacturing from multiple aspects.

Technical features and advantages

High precision and stability

SICK sensors use a variety of advanced sensing technologies, such as lidar, ultrasound, infrared, etc., which ensure the high precision and stability of sensors in measurement and perception.

For example, lidar sensors have ultra-high ranging accuracy and fast response capabilities, and can provide accurate environmental perception information for intelligent driving, such as obstacles, lane lines, traffic signals, etc. around the vehicle.

This high precision and stability not only improves the quality control level in the automobile manufacturing process, but also enhances the reliability and safety of the product.

Fast response and real-time performance

SICK sensors have extremely fast response speeds, can perceive changes in the surrounding environment in real time, and quickly transmit data to the control system. This real-time performance is essential for dynamic control and adjustment in the automobile manufacturing process. For example, in the body welding process, the sensor can monitor the position and width of the weld in real time to ensure the stability of the welding quality; in the spraying process, it can accurately control the spraying amount and spraying position to avoid waste and pollution.

Multifunctional integration and intelligence

SICK sensors can integrate multiple sensing functions into one, reducing the size and weight of the sensor, while reducing the complexity and cost of the system. In addition, the sensor also has a certain intelligent processing capability, which can analyze and judge the collected data and provide more valuable information. This intelligent feature enables the sensor to better adapt to complex production environments and improve production efficiency and product quality.

Application in automobile manufacturing

Environmental perception and intelligent driving

In the field of intelligent driving, SICK sensors play a vital role. LiDAR sensors can accurately perceive the environmental information around the vehicle and provide accurate data support for functions such as autonomous driving, automatic parking, and adaptive cruise. The realization of these functions not only improves the safety and comfort of driving, but also promotes the development of automobiles towards a more intelligent and automated direction.

Battery Management and New Energy Vehicles

In the field of new energy vehicles, SICK’s pressure sensors and temperature sensors play a key role in battery management systems. They can monitor the status of the battery, such as voltage, current, temperature, etc., in real time to ensure that the battery operates in the best condition. This precise battery management not only extends the battery life, but also improves the driving safety and performance of new energy vehicles.

Body welding and spraying

In the body welding and spraying process, SICK sensors also show excellent performance. The sensor can monitor the position and width of the weld in real time to ensure the stability of the welding quality; during the spraying process, it can accurately control the spraying amount and spraying position to avoid waste and pollution. These applications not only improve production efficiency, but also reduce production costs and environmental pollution.

Quality control on the production line

On the automobile production line, SICK sensors can be used for quality control in multiple links. For example, during the installation of parts, the sensor can accurately measure and locate the position and status of the parts to ensure the accuracy and consistency of the installation. This quality control method not only improves the overall performance of the product, but also significantly reduces the defective rate.

Enhance new advantages in automobile manufacturing

Improve production efficiency

The high precision, fast response and real-time characteristics of SICK sensors make the automobile manufacturing process more efficient. Sensors can monitor and control each link in the production process in real time to ensure the continuity and stability of production. This efficient production method not only improves production efficiency, but also reduces production costs and energy consumption.

Improve product quality

Through precise environmental perception and data monitoring, SICK sensors can ensure the quality control level in the automobile manufacturing process. Sensors can monitor and adjust key parameters in the production process in real time to ensure that the quality of each component and vehicle meets strict standards. This quality control method not only improves the reliability and safety of the product, but also enhances the market competitiveness of the product.

Promote intelligent development

The intelligent characteristics of SICK sensors make the automobile manufacturing process more intelligent. Sensors can be interconnected with other intelligent devices to realize real-time collection, analysis and processing of production data.

This intelligent application not only optimizes the production process and management methods, but also brings higher economic benefits and market competitiveness to enterprises.

At the same time, with the continuous advancement of automobile technology and changes in market demand, SICK sensors will continue to play an important role in promoting the development of the automobile manufacturing industry towards a more intelligent, safe and efficient direction.

Conclusion

In summary, SICK sensors have demonstrated strong competitiveness in the field of automobile manufacturing with their excellent technical characteristics and wide application advantages.

Through the application of high precision, fast response, real-time, multi-functional integration and intelligence, SICK sensors not only improve the production efficiency and product quality of automobile manufacturing, but also promote the intelligent development of the automobile manufacturing industry.

In the future, with the continuous advancement of automobile technology and changes in market demand, SICK sensors will continue to play an important role and bring more new advantages and opportunities to the automobile manufacturing industry.

FAQs

A SICK sensor is a high-performance sensor device that uses photoelectric devices as conversion elements. It can detect changes in light and other non-electrical quantities (such as part diameter, speed, etc.) and convert them into electrical signals. The sensor has the characteristics of non-contact, fast response, and reliable performance. It is widely used in industrial automation devices and robots, becoming the “smart eye” of industrial automation production.

As a world-leading sensor manufacturer, SICK continues to promote technological innovation and provide strong technical support for all walks of life.

SICK sensors are produced in Germany. The company was founded by Dr. Erwin Sick in 1946 and is headquartered in Waldkirch in southwestern Germany. SICK sensors are known for their high performance, high reliability and wide range of applications. It is one of the world’s leading manufacturers of sensors and sensor solutions. The company not only occupies an important position in the European market, but also has established a large sales and service network worldwide to provide high-quality sensor products and services to all walks of life.

If the SICK sensor cannot be turned on normally or is frequently powered off, first check whether the power supply is stable. If the power supply is normal, further check the cable connection, whether the power line is short-circuited or broken, and whether the internal circuit of the sensor is burned. These checks help determine whether the sensor cannot work properly due to power failure or line problems.

When the sensor cannot detect objects normally or detects them incorrectly, first check whether the sensor is interfered with by external factors, such as dust, oil, etc. Clean the surface of the sensor and ensure that the distance between the sensor and the detected object is within the specified range. If the problem is still not solved, it may be that the internal components of the sensor are damaged and need to be replaced or repaired.

In case of communication failure, first check whether the communication line is connected correctly to eliminate the possibility of poor line contact or open circuit. At the same time, check whether the communication protocol is set correctly to ensure that the communication parameters of the sensor and other devices are consistent. If the problem persists, it may be that the communication chip or interface of the sensor itself is damaged and needs to be repaired or replaced.

If the SICK sensor value is always zero during the weighing process, possible reasons include sensor damage, circuit breakage, signal transmitter failure or poor contact of the junction box. During the inspection, you can first check the voltage value of the sensor output signal line to determine whether the sensor is damaged; then check whether the line is broken; then check whether the signal transmitter is working properly; finally check whether the junction box is in good contact.

The methods for maintaining and maintaining SICK sensors include regular cleaning of the sensor surface, especially the sensor part, to avoid dust and oil stains affecting the detection accuracy. At the same time, pay attention to check whether the sensor cable and connecting lines are intact to avoid failures caused by aging or damage of the line. In addition, regular calibration should be performed according to the sensor model and function and the operating manual to ensure the accuracy of the measurement results.

The working principle of SICK sensors often uses photoelectric elements as detection elements to convert the mass signal of the object into a measurable electrical signal output. Photoelectric sensors generally consist of three parts: light source, optical path and photoelectric element. The existence, position or shape of the object is detected by the change of light signal.

SICK sensors are widely used in industrial automation, robot navigation, logistics tracking, safety detection and other fields, providing accurate and reliable detection and control functions for various equipment and systems.