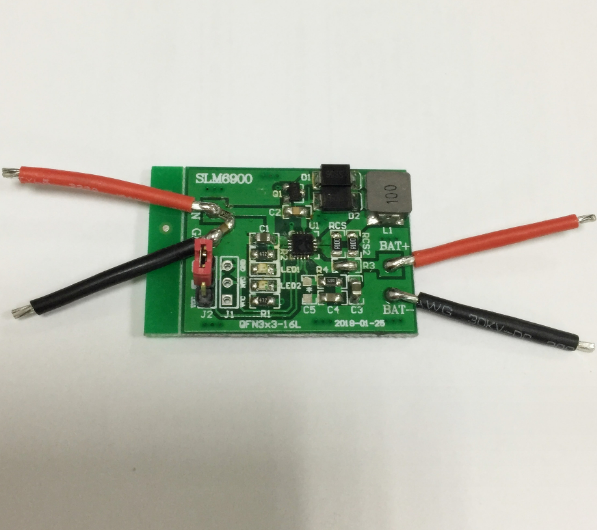

Manual assembly of electronic components onto PCB boards is an important electronic process technology.

By using suitable tools and materials, electronic components are placed on the PCB board one by one and soldering techniques are used to fix them in the correct position.

During the welding process, attention needs to be paid to the welding time and temperature to ensure good welding quality. Finally, the welding results need to be checked to ensure that there are no virtual welds, missing welds, etc.

Manual assembly of electronic components onto a PCB requires care and patience. For beginners, it is recommended to learn relevant knowledge and skills first, and then gradually try to assemble simple electronic components.

The steps for manually assembling electronic components onto a PCB board are as follows:

Preparation for manual assembly of electronic components

PCB board

Ensure that the PCB board is of good quality, free from damage and pollution. Check whether the pads on the PCB are clear and free of oxidation.

Electronic Component

Check the parts list to make sure all required components are present. Check whether the specifications, models, and quantities of components are consistent with the list.

Component assembly tools

Prepare soldering tools, such as soldering iron, solder, flux, tweezers, scissors, etc. Make sure tools are clean and undamaged.

Electronic component assembly environment

Keep the work area tidy and avoid dust and debris. Make sure the work area is well lit and easy to operate.

Component preprocessing

clean

Use an alcohol cotton ball or soft cloth to gently wipe the pins and surfaces of the components to remove oxides and stains.

Bent feet

According to the pad spacing on the PCB board, appropriately adjust the length and curvature of the component pins. Pay attention to the even distance between the pins to avoid short circuits.

Component classification

Classify components according to type and specification to facilitate subsequent operations.

Component insertion and fixation

identify

Identify the insertion position and direction of components according to the silk screen and circuit diagram on the PCB. Pay attention to the positive and negative polarities and avoid plugging them in reverse.

Insert and place components

Place electronic components on the PCB board, paying attention to the polarity and direction of the components. Use tweezers to gently hold the component’s pins and insert them into the corresponding pads on the PCB. Make sure the pins are in tight contact with the pads and there is no looseness.

Fix electronic components on PCB board

For large components or components that are easy to loosen, tape or clips can be used to temporarily fix them to prevent them from shifting during the welding process. Use tweezers to gently hold the component’s pins and insert them into the corresponding pads on the PCB. Make sure the pins are in tight contact with the pads and there is no looseness. For large components or components that are easy to loosen, tape or clips can be used to temporarily fix them.

Solder pins

Use a soldering iron to melt the solder, and apply the melted solder to the pins of the components and the pads of the PCB board. Then touch the pin and pad with a soldering iron tip and solder the pin and pad together. Note that the welding time should not be too long to avoid damaging the components or PCB board.

Check welding quality

Check whether the welding is firm and whether there are any weak welding, missing welding, etc. If poor welding is found, it should be repaired or re-welded in time.

Post-processing

Cut off excess pins and gently wipe the PCB surface with an alcohol cotton ball or soft cloth to remove stains and oxides produced during the soldering process. Carry out functional tests to ensure that all circuits function normally and there are no short circuits or open circuits.

It should be noted that manual assembly of electronic components onto a PCB board requires certain skills and experience. For beginners, it is recommended to learn relevant knowledge and skills first, and then gradually try to assemble simple electronic components. At the same time, pay attention to safety during operation to avoid accidents such as burns and electric shock.

Welding

Soldering iron preheating

Heat the soldering iron to the appropriate temperature, generally between 260 and 300°C. Before welding, you can use solder wire to apply a layer of flux on the soldering iron to improve the welding quality.

Electronic component welding

Place the solder wire close to the soldering iron tip. After the solder melts, quickly move the solder wire to the contact between the component pin and the pad. At the same time, use a soldering iron to gently press the component pins to solder them tightly to the pads. Note that the welding time should not be too long to avoid damaging the components or PCB board.

Electronic component inspection

After welding is completed, check the welding quality with the naked eye or a magnifying glass. Make sure the solder joints are smooth, with no empty soldering or continuous soldering. For unqualified solder joints, repair welding or re-welding is required.

Post-processing

Cut off excess component pins on the PCB board

After soldering is complete, use scissors to cut off the excess pins. Pay attention to leaving a certain length when cutting the feet to avoid cutting into the solder joints.

Clean PCBA board after soldering

Use an alcohol cotton ball or soft cloth to gently wipe the surface of the PCB board to remove stains and oxides produced during the soldering process.

Check the components on the PCB

Check again whether all components on the PCB have been soldered correctly, with no omissions or errors. Unqualified components or solder joints need to be repaired or replaced.

Test the PCB board with assembled components

Connect the PCB board to the test equipment for functional testing. Make sure that all circuits are functioning properly and there are no short circuits or open circuits.

Precautions

Safety

During the manual assembly process, pay attention to safe operation to avoid accidents such as burns and electric shock.

quality

Strictly control the welding quality to ensure that every solder joint meets quality requirements. Unqualified solder joints or components must be repaired or replaced in a timely manner.

efficiency

On the premise of ensuring quality, try to improve the efficiency of manual assembly. Work efficiency can be improved by properly arranging work sequences and selecting appropriate tools and methods.

Five-step method for hand soldering electronic components

The five-step method for hand soldering electronic components includes:

- Prepare for soldering: Prepare soldering wire and soldering iron. At this time, it is particularly emphasized that the head of the soldering iron must be kept clean, that is, it can be stained with solder (commonly known as eating tin).

- Heating the soldering piece: Touch the soldering iron to the soldering point. Firstly, keep the soldering iron heating all parts of the soldering piece, such as the leads and pads on the printed circuit board, so that they are heated. Secondly, pay attention to the flat part (larger part) of the soldering iron tip. ) contact the weldment with a larger heat capacity, and the side or edge part of the soldering iron tip contacts the weldment with a smaller heat capacity to keep the weldment evenly heated.

- Melt the solder: When the weldment is heated to a temperature that can melt the solder, place the solder wire on the solder joint, and the solder begins to melt and wet the solder joint.

- Remove the solder: When a certain amount of solder is melted, remove the solder wire.

- Remove the soldering iron: When the solder completely wets the solder joint, remove the soldering iron. Note that the direction of removing the soldering iron should be approximately 45°.

The above is the five-step method for hand soldering electronic components. If you need customized component procurement, or have electronic component procurement requirements, please contact us.

Introducing the application scenarios of manually assembling electronic components to PCB boards

Manual assembly of electronic components onto a PCB requires the following materials:

- PCB board: The mounting carrier for electronic components needs to be made of good quality, high temperature resistant and corrosion resistant materials.

- Electronic components: Select appropriate components according to the circuit diagram and design requirements, and ensure reliable quality.

- Welding tools: including soldering iron, solder, flux, tweezers, etc., used for soldering electronic components to PCB boards.

- Assembly tools: including screwdrivers, wrenches, pliers, etc., used to fix electronic components on the PCB board.

- Test tools: including multimeters, oscilloscopes, etc., used to test the function and performance of the circuit.

- Other auxiliary materials: including insulating tape, protective film, gaskets, springs, etc., used to protect circuit boards and electronic components.

It should be noted that different electronic components and circuit designs require the use of different materials and tools, and the specific selection should be based on the actual situation. At the same time, pay attention to safety during operation to avoid accidents such as burns and electric shock.