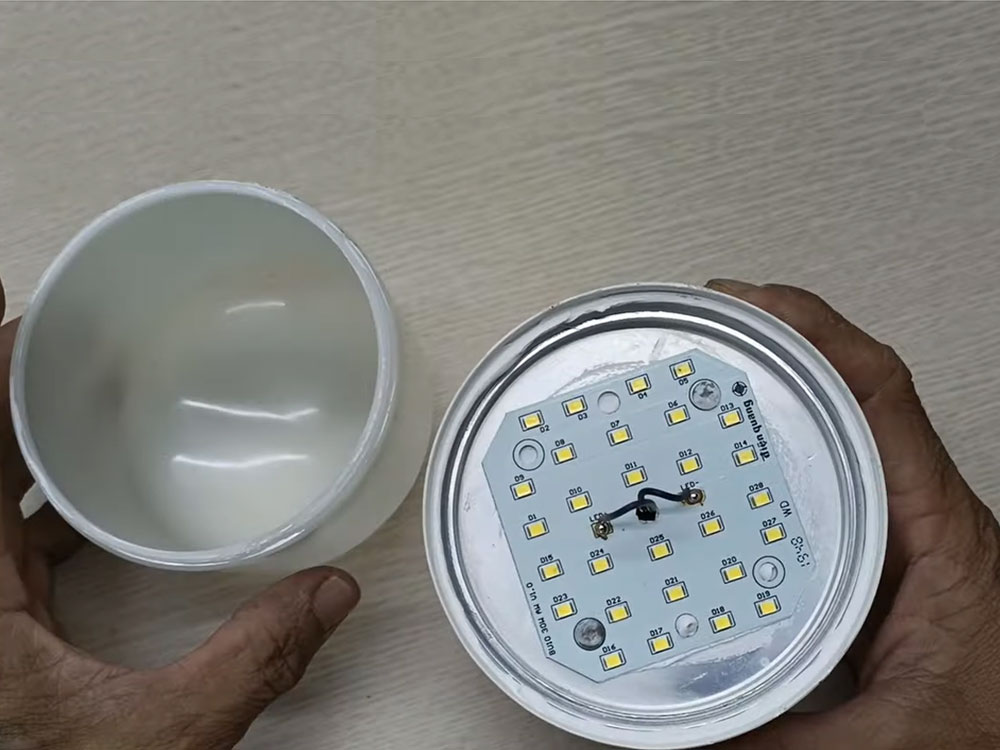

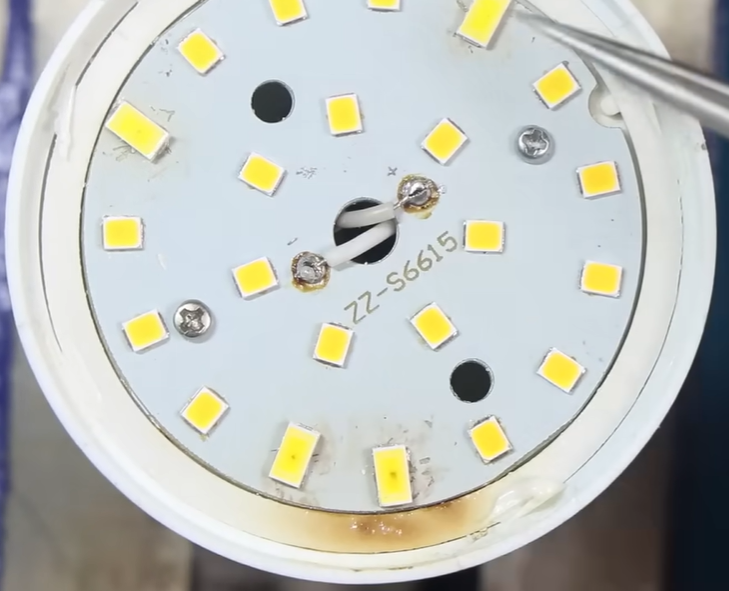

The list of electronic components on high-power LED PCB includes high-power LED lamp beads, resistors, capacitors, diodes, integrated circuits, inductors, switches, connectors, heat sinks, screws, etc.

These components together ensure the normal operation of high-power LEDs.

What is high power LED

High-power LED refers to a light-emitting diode with a large rated operating power. The power of ordinary LEDs is generally 0.05W and the operating current is 20mA, while high-power LEDs can reach 1W, 2W, or even tens of watts, and the operating current can range from tens of milliamperes to hundreds of milliamperes.

Due to the constraints of high-power LEDs in terms of luminous flux, conversion efficiency and cost, it is determined that the short-term application of high-power white LEDs is mainly lighting in some special fields, and the medium- and long-term goal is general lighting.

High-power LEDs are mainly composed of metal substrates (such as aluminum substrates) with good heat dissipation properties, chips, packaging materials, etc. The chips usually use semiconductor materials such as gallium nitride (GaN), and the built-in PN junction can convert electrical energy into light energy. Encapsulating materials are used to protect the chip, and reflective materials are added at the light exit to improve light output efficiency.

As the fourth generation electric light source, high-power LED is known as the “green lighting source”. It has excellent characteristics such as small size, safe low voltage, long life, high electro-optical conversion efficiency, fast response speed, energy saving, and environmental protection. It will definitely replace the traditional Incandescent lamps, tungsten halogen lamps and fluorescent lamps have become a new generation of light sources in the 21st century.

Electronic component list on high-power LED PCB

Today we show some of the electronic components that may be included on a high-power LED PCB. However, this is only a very basic example and the exact component list will vary based on specific application requirements and circuit design.

List of electronic components on high-power LED PCB:

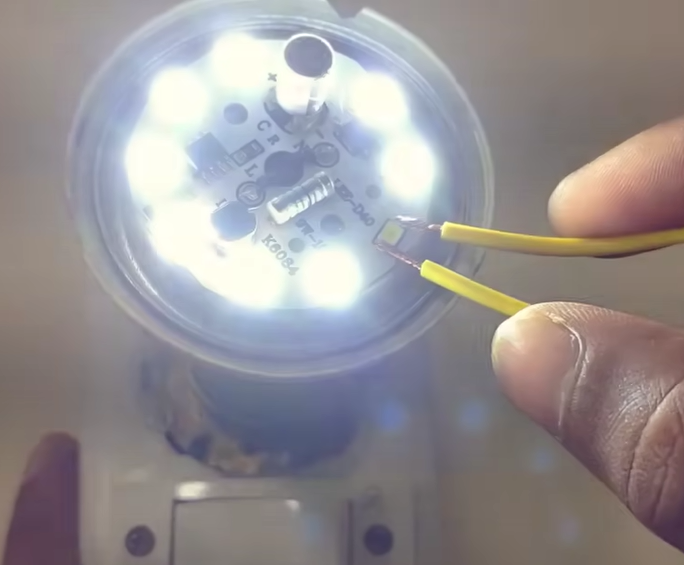

- High-Power LED: This is the main component of the PCB and is responsible for generating light. Depending on the need, there may be multiple LED lamp beads.

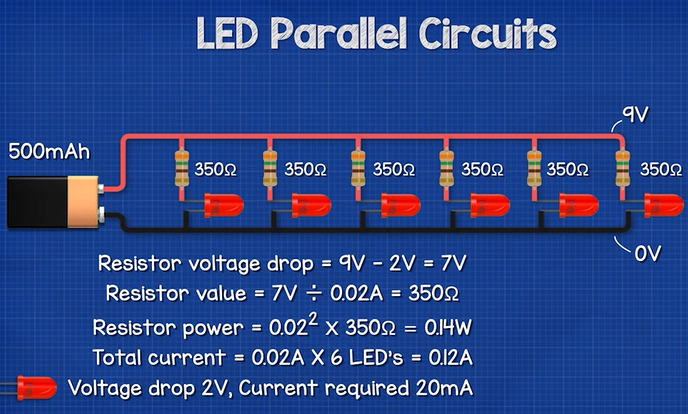

- Resistors: used to limit current and prevent LED from overheating or overcurrent. There are usually some fixed resistors and variable resistors.

- Capacitors: used to filter the power supply and reduce noise and interference in the power supply.

- Diodes: Usually Schottky diodes, used to prevent reverse current flow.

- Integrated Circuits: such as control IC, driver IC, etc., used to manage and control the working status of LEDs.

- Inductors: Used to filter out high-frequency noise and may also be used for power supply filtering.

- Switches: used to control the on and off of circuits.

- Connectors: Used to connect the PCB to external power and control signals.

- Heat Sinks: If the LED requires high power operation, additional heat sinks may be needed to help dissipate heat.

- Screws, glue and other fixings: used to fix components and PCBs.

The selection and configuration of these components requires detailed design and calculation based on LED specifications, operating voltage and current, operating temperature, power supply, and other related factors.

In actual applications, professional electronic engineers or designers with relevant experience will make these calculations and selections.

NOTE: This list is not exhaustive and may not apply to all situations. The specific design will depend on many factors, including but not limited to the specifications of the LED, the operating voltage and current of the circuit, the size and layout of the PCB, cost budget, etc.

In actual applications, it is recommended to consult a professional electronics engineer or manufacturer to ensure that the design and component selection meet specific needs.

High Power LED PCB Design and Manufacturing Considerations

In addition, for the design and manufacturing of high-power LED PCB, the following factors also need to be considered:

- Heat dissipation design: High-power LEDs will generate a lot of heat, so an effective heat dissipation solution is required. This may involve PCB layout, thermal material selection, and heat sink design.

- Power supply design: Stable power supply needs to be provided to the LED to maintain its performance and lifespan. This involves considerations such as power management, voltage regulation, and current limiting.

- Electromagnetic compatibility (EMC): It is necessary to ensure that the PCB does not produce excessive electromagnetic interference when working, and it must also be able to resist external electromagnetic interference.

- PCB materials and processes: Appropriate PCB materials and manufacturing processes need to be selected to ensure its electrical performance, mechanical strength, heat resistance, etc.

- Wiring design: Reasonable wiring design needs to be carried out according to circuit requirements to ensure electrical performance and reduce electromagnetic interference.

- Safety requirements: For some application fields, such as lighting, automobiles, etc., relevant safety requirements need to be met, such as CE certification, UL certification, etc.

- Maintainability and Replaceability: The replacement and maintenance of components need to be considered to ensure the reliability and lifespan of the entire system.

To sum up, the design of high-power LED PCB is a complex process that requires comprehensive consideration of multiple factors. If you have specific needs or questions about this, it is recommended to consult a professional electronics engineer or manufacturer.

What are the characteristics of high-power LED electronic components?

High-power LED electronic components have the following characteristics:

- High brightness: The luminous efficiency of high-power LED is more than 10 times higher than traditional incandescent lamps and about 2 times higher than fluorescent lamps.

- High efficiency: High-power LEDs have extremely high power conversion efficiency and can produce a large amount of luminous flux with low power consumption.

- Long lifespan: High-power LEDs have an extremely long lifespan and can be used for more than 50,000 hours, which is more than 40 times that of traditional incandescent lamps.

- Small size and high reliability: The high-power LED device itself is very small and has a long service life, so it has higher reliability.

- Mercury-free and environmentally friendly: High-power LED does not contain any harmful substances used for lighting, such as mercury, etc., and is very environmentally friendly.

- Safe Low Voltage: High-power LEDs work at safe low voltage and will not cause harm to the human body.

- Good weather resistance: High-power LED can work in different environments, such as high temperature, low temperature, humidity, exposure, etc.

- Good directionality: The light emitted by high-power LED has strong directionality and can be used for spotlight or flood lighting.

- No delay in startup: The high-power LED reaches normal brightness almost immediately after powering on, eliminating the long startup process of traditional street lights.

- No flicker: Pure DC operation eliminates visual fatigue caused by traditional street lamp flicker.

- No adverse glare: It has a wide range of uses and eliminates the discomfort of human eyes caused by ordinary street lights due to adverse glare.

- Volt-ampere characteristics: High-power LED lamp beads are low-voltage, high-current driving devices. When the voltage of the LED lamp beads fluctuates very little, large current changes will occur.

- Light characteristics: According to the luminous principle of LED lamp beads, the luminous brightness of LED lamp beads basically changes positively with the current of the LED lamp beads. The essence of controlling the luminous brightness of high-power LED lamp beads is to control its output luminous flux.

- Temperature characteristics: The forward current of LED lamp beads also changes with temperature. If the ambient temperature exceeds a certain value, the allowable forward current of the white LED lamp beads will be greatly reduced. In this case, if a large current is still applied, it will easily cause the white LED lamp beads to age.

The above are the characteristics of high-power LED electronic components. I hope they can help you.

Purchasing LED electronic components

When purchasing LED electronic components, you need to consider the following factors:

- Component specifications: It is necessary to clarify the specifications of the required components, including voltage, current, power, size and packaging, etc.

- Quality Assurance: Choose reliable brands and suppliers to ensure the quality and performance of components.

- Price Comparison: You need to compare prices from different suppliers to find the most cost-effective option.

- Delivery Time: The supplier’s delivery time needs to be taken into account to ensure that the production schedule is not affected.

- Inventory Status: It is necessary to know the supplier’s inventory status to ensure whether the required components are available in stock.

- Technical Support: Choose a supplier that can provide technical support and after-sales service to ensure that problems encountered during production and use can be solved in a timely manner.

- Payment Method: A suitable payment method needs to be agreed with the supplier to ensure the smooth progress of the transaction.

When choosing a supplier, consider the following factors:

- Company size and strength: Choose suppliers with larger scale and stronger strength to ensure the quality of components and the stability of supply.

- Product Type and Specifications: You need to choose a supplier that can provide the required types and specifications of components.

- Price and Service: It is necessary to compare the prices and services of different suppliers to find the most cost-effective option.

- Delivery Speed: It is necessary to choose a supplier that can deliver quickly to ensure that the production schedule is not affected.

- Technical Support: It is necessary to choose a supplier that can provide technical support and after-sales service to ensure that problems encountered during production and use can be solved in a timely manner.

- Brand Reputation: It is necessary to choose suppliers with good brand reputation to ensure the quality and performance of components.

- Payment Method: You need to choose a supplier that can provide flexible payment methods to ensure the smooth progress of the transaction.

In short, when purchasing LED electronic components, you need to consider multiple factors and choose the right supplier.

At the same time, during production and use, attention needs to be paid to the quality and performance of components and to ensuring safety and reliability.

Companies that provide LED electronic components

Thank you for choosing us, here we will provide you with the most suitable LED electronic components procurement solution, we are an electronic component manufacturer in China, my name is AnWen, I am an electronics enthusiast, our company is engaged in Electronic components procurement and sales, electronic circuit design, circuit board manufacturing and assembly services, you are welcome to contact us.

Our company is in Shenzhen, China. I have established good cooperative relationships with many foreign friends. They have my WeChat. If you want to get close To communicate with me from a distance, please add my WeChat, my WeChat: +8618062443671.

Frequently asked questions and answers for purchasing high-power LED electronic components:

The brightness of the LED mainly depends on the size of the current. When current flows through the LED lamp bead, the lamp bead will emit light, and the brightness will increase as the current increases. But at the same time, it should be noted that excessive current may burn the lamp beads, so it is necessary to choose an appropriate current value.

The lifespan of an LED mainly depends on its quality and working environment. Good quality LED lamp beads have a longer lifespan, and the temperature and humidity of the working environment will also affect their lifespan. Working in high temperature and high humidity environments, the life of LED lamp beads will be shortened. In addition, the size of the current will also affect its life, so it is necessary to choose an appropriate current value.

Choosing the right LED requires considering parameters such as voltage, current, power, color and size. The selection needs to be based on specific application requirements and circuit design to ensure that the LED can work properly and achieve the desired effect.

The polarity of LED refers to the positive and negative poles of LED lamp beads. In the circuit, current needs to flow from the positive terminal of the LED to the negative terminal in order for it to emit light. If the positive and negative poles are connected reversely, the LED will not emit light and may burn out. Therefore, you need to pay attention to the polarity of the LED when installing and soldering.

The viewing angle of an LED refers to the size of its light-emitting angle. Different types of LEDs have different light-emitting angles, and choosing the appropriate light-emitting angle can better meet application needs. Generally speaking, small-angle LEDs are suitable for spot lighting and directional lighting, while large-angle LEDs are suitable for flood lighting and ambient lighting.

Our company has passed ISO9001 quality management system certification and ISO14001 environmental management system certification. In addition, we have also obtained international certifications such as UL, CE, and RoHS, and can provide high-quality LED electronic components that meet international standards.

Our products have the advantages of high reliability, high brightness, long life, and low power consumption. At the same time, we also provide customized services and can customize production according to customer needs to meet customers’ special needs.

Our delivery time is usually 5-7 working days, but the specific time needs to be determined according to the quantity of the order and the type of product. We will do our best to ensure product production and delivery time to meet customer needs.

We provide complete after-sales service. If customers encounter any problems during use, we can provide technical support and solutions and solve customer problems as soon as possible. At the same time, we also provide product warranty services to ensure product quality.

Our prices are determined according to the type and specification of the product, and are also affected by market supply and demand. We will formulate price strategies based on customer needs and market conditions, and provide cost-effective products.