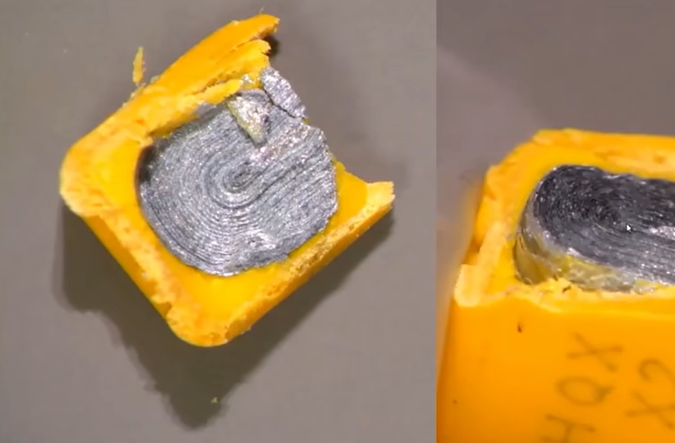

The self-healing process of a self-healing capacitor mainly relies on its internal self-healing dielectric. This dielectric usually consists of a metallized film and an insulating medium.

When the capacitor is impacted by overvoltage or overcurrent, breakdown may occur in local areas of the metallized film, resulting in a short circuit.

However, due to the self-healing properties of dielectric materials, the metallized film around the breakdown point will quickly evaporate and escape, forming a blank area, allowing the breakdown point to automatically restore insulation.

Specific process steps for self-healing capacitors to achieve self-healing

The specific process of self-healing capacitors to achieve self-healing can be divided into the following steps:

Breakdown occurs

When the capacitor is impacted by overvoltage or overcurrent, breakdown may occur in a local area of the metallized film, resulting in a short circuit.

The metallized film around the breakdown point evaporates and escapes

Due to the self-healing characteristics of the dielectric material, the metallized film around the breakdown point quickly evaporates and escapes, forming a blank area.

Automatic restoration of insulation

Due to the formation of a blank area around the breakdown point, the breakdown point automatically restores insulation. This process is transient and usually only takes a few microseconds to tens of microseconds.

Maintain normal operation

After the self-healing process is completed, the self-healing capacitor can continue to maintain normal operation without affecting other parts of the system.

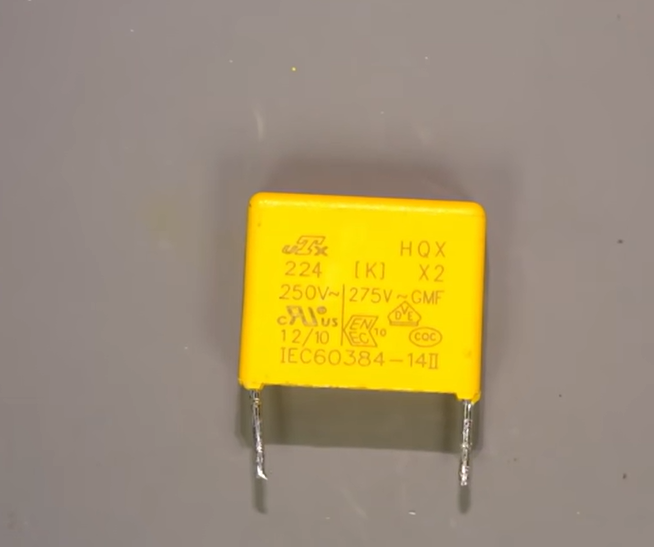

Capacitor expert and AVX Fellow Ron Demcko confirms what’s really going on after a teardown of some failed and one good polypropylene X class capacitor.

Key factors for self-healing capacitors to achieve self-healing

Self-healing properties of dielectric materials

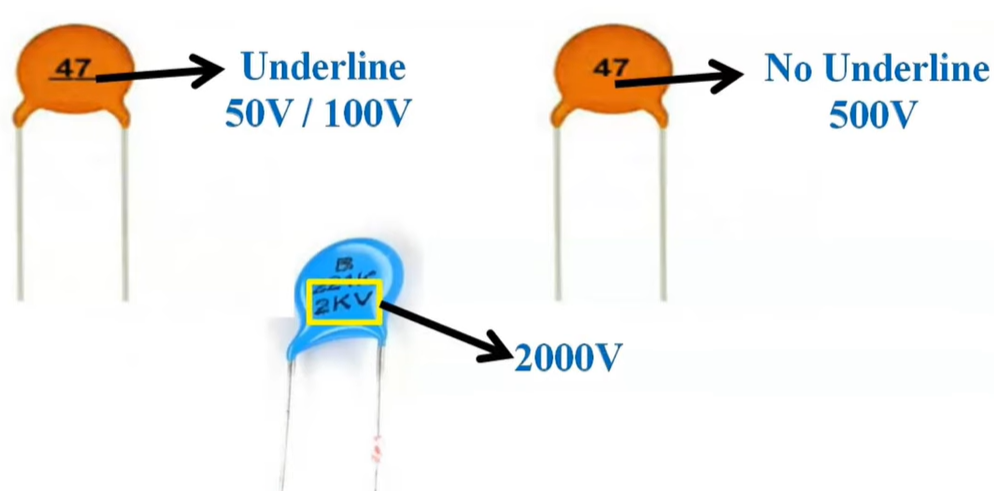

The dielectric materials used in self-healing capacitors must have high withstand voltage and current capabilities, as well as good self-healing properties. This is the basis for the self-healing process.

Uniformity and thickness of metallized film

The uniformity and thickness of metallized film are very important to prevent breakdown and achieve self-healing. A uniform metallization film can reduce current density and avoid premature breakdown. Proper metallization film thickness can improve the ability to withstand current surges.

Manufacturing process

The manufacturing process is critical to the performance and reliability of self-healing capacitors. Environmental conditions such as temperature, humidity, cleanliness, etc. need to be strictly controlled during the manufacturing process to ensure product quality and stability.

System protection circuit

Although self-healing capacitors have self-healing capabilities, they may still fail under extreme circumstances. Therefore, protection circuits in the system are crucial to ensure safe operation. The protection circuit can detect abnormal conditions such as overvoltage and overcurrent, and take corresponding measures to prevent the fault from expanding.

The self-healing process of self-healing capacitors is a complex physical and chemical process involving the combined action of multiple factors.

By continuously optimizing materials, design and manufacturing processes, the performance and reliability of self-healing capacitors can be improved, providing better guarantee for the stable operation of the power system.

Capacitor self-healing process and mechanism analysis

We Focus on manufacturing and exporting various kinds of Power Electronic Components for more than 34 years.

If interest, plz contact us here now.

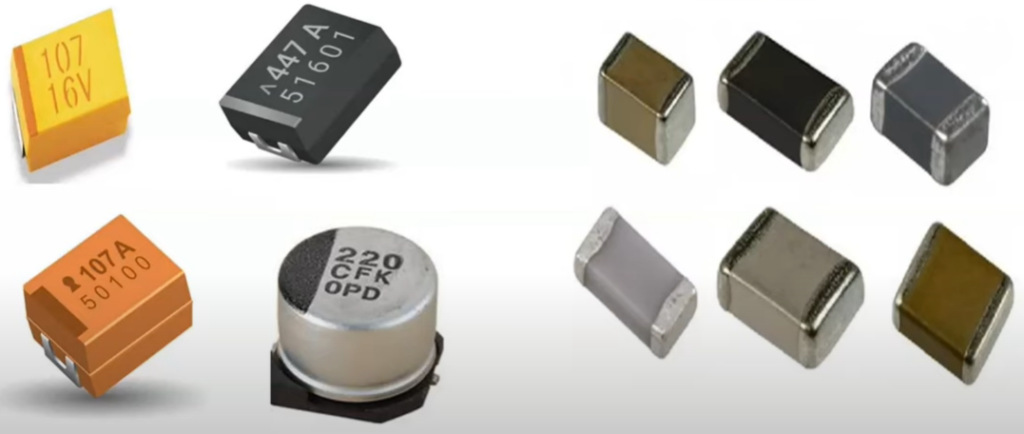

Capacitor is a common electrical component, mainly composed of two electrodes, a medium and polar inorganic compounds called “self-healers”.

When the capacitor is impacted by overvoltage or overcurrent, the self-healer begins to work and releases the charge to the “ground”. This process is called the “self-healing” process of the capacitor. It can not only avoid damage to the capacitor, but also play an important role in circuit protection and stable power supply.

The mechanism of capacitor self-healing process includes the following aspects:

- Reasons why the self-healing process occurs

When the capacitor is impacted by a large voltage or current, charges accumulate on the surface of the medium, causing the local electric field of the medium to exceed the withstand electric field strength of the material, leading to breakdown accidents. If a self-healing capacitor is installed in the capacitor, the polar inorganic compound of the self-healing device can be decomposed into ions immediately and discharge the charge to the “ground” through its own polarity path, thus maintaining the safe operation of the capacitor.

- Mechanism of self-healing process

Under normal working conditions, the resistance of the self-healer is relatively large and will not affect the power supply of the circuit. When the capacitor is impacted, charges will quickly accumulate at both ends of the self-healer, causing the potential difference of the self-healer to be higher than the breakdown potential of the medium, resulting in the decomposition of the self-healer. The decomposition of the self-healer produces a large amount of electrons and oxygen (in the aluminum oxide self-healer). These particles carry away the charge and generate a brief high temperature during the self-healing process. At this time, the self-healer can discharge the charge to the “ground”.

- Selection of self-healing device

In practical applications, many factors need to be considered when selecting a self-healer to ensure that it can work under appropriate conditions. The most important factors are the capacitor’s rated voltage and operating current. In addition, different self-healing materials also have different abilities to withstand different voltages. In order to ensure stability, reliable self-healing materials need to be selected.

- Handling of difficult problems

Although the self-healing process helps protect capacitors from excessive voltage or current, sometimes the self-healer may fail. In this case, a possible solution is to replace the healer or the entire capacitor. In addition, you can also consider adding a protection circuit to the circuit so that even if the capacitor is impacted by overcurrent or voltage, it can still maintain safe operation.

In short, the self-healing process of the capacitor is an important protection mechanism and plays a vital role in the stability and reliability of the circuit. It should be noted that the selection of a suitable self-healer is particularly critical to ensuring the stability and safety of the capacitor.

Self-healing capacitor manufacturers and wholesalers in China

Manufacturers and wholesalers of self-healing capacitors in China include many well-known companies, such as Chint Electric, Yunye, Yageo Co., Ltd. (referred to as Yageo Chip Capacitor Company), China Electric Equipment, Haoshang Hao Holdings, Taikeyuan, etc.

These companies are committed to developing and producing high-quality self-healing capacitors. Their products are widely used in electronic equipment, power systems and other fields, and have the advantages of high efficiency, stability, and high reliability.

At the same time, these companies also provide wholesale services to meet the needs of different customers.

Of course you can contact us. We are a professional wholesaler and supplier of electronic components and a professional manufacturer of self-healing capacitors.

We provide capacitor products with self-healing capabilities. These capacitors can automatically repair when a fault occurs to ensure the stability of the system. run. Manufacturers are committed to continuously developing new technologies and products to meet customers’ needs for efficiency, stability, and high reliability.