Electronic component procurement quality control technology is a key link in ensuring the quality and reliability of electronic products.

With the rapid development of the electronics industry, the types and quantities of electronic components are increasing, and the requirements for quality control technology are becoming higher and higher.

This article will introduce the quality control technology of electronic component procurement in detail to provide comprehensive understanding and guidance.

Overview

Electronic component procurement quality control technology refers to the quality inspection, testing and control of purchased electronic components through a series of technologies and means to ensure that they meet design requirements and reliability standards. Quality control technology involves many aspects, including appearance inspection, performance testing, reliability and life evaluation of components.

Key elements

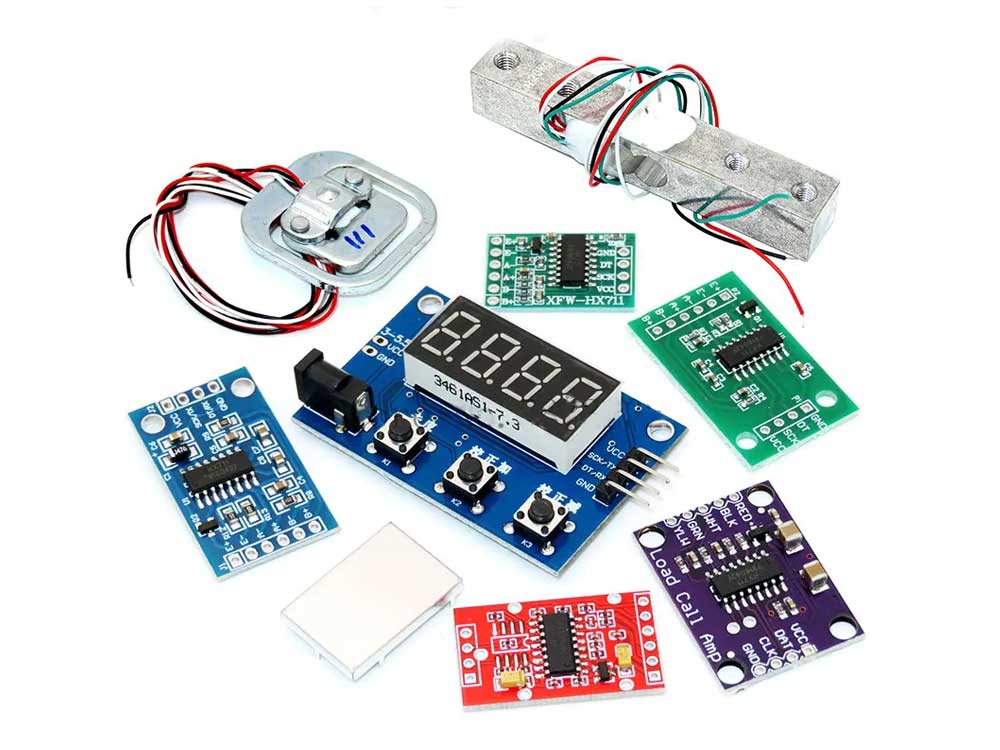

- Appearance inspection

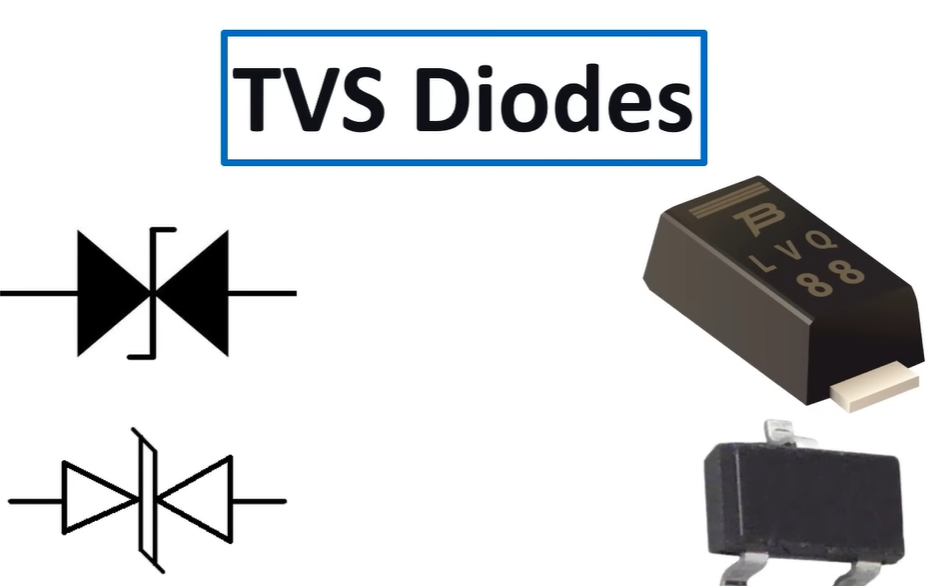

Appearance inspection is one of the most basic procurement quality control techniques. By inspecting the appearance dimensions, surface quality, markings and packaging, we can preliminarily judge whether the components meet the requirements. Appearance inspection is generally performed using visual or automatic inspection equipment. - Performance testing

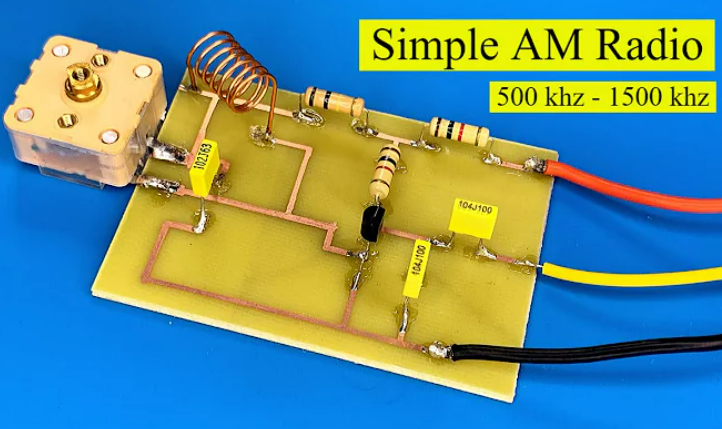

Performance testing is an important means to evaluate the function and performance of components. Through testing, it can be determined whether the electrical parameters, frequency characteristics, temperature characteristics, etc. of the components meet the design requirements. Performance testing is generally performed using automatic testing equipment, and corresponding testing specifications and standards need to be formulated. - Reliability and Lifetime Assessment

Reliability and life assessment is a test of the long-term stability of components. The life and reliability of components are analyzed through accelerated aging tests, life tests, etc. This process needs to be carried out under specific environmental conditions, such as high temperature, low temperature, high humidity, etc., to accelerate the aging process of components. - Quality assurance system

Establishing a complete quality assurance system is the key to ensuring the quality of purchased components. The quality assurance system should include supplier selection and evaluation, procurement process control, inspection and testing, handling of non-conforming products, etc., and the system needs to be reviewed and updated regularly. - Information management

Adopting information management methods, such as establishing an electronic components database and using a procurement management system, can realize information sharing, process optimization and data statistics and analysis in the procurement process, and improve procurement efficiency and quality control levels.

Application and practice

In practical applications, electronic component procurement quality control technology should be selected and applied based on specific needs and actual conditions. The following are some common application scenarios and practical experiences:

- Supplier selection and evaluation: When selecting suppliers, a comprehensive evaluation of the supplier’s qualifications, quality assurance capabilities, product performance, etc. should be conducted. Supplier evaluation scales and other methods can be used for evaluation and scoring to ensure reliable supplier quality.

- Formulation of inspection and testing plans: Develop corresponding inspection and testing plans based on the type, specifications and usage requirements of components. The plan should include appearance inspection, performance testing, reliability and life evaluation, etc., and clarify the testing methods and qualification standards.

- Disposal of unqualified products: Unqualified components should be identified, isolated and processed. The processing method can be returned, exchanged or scrapped according to the actual situation, and the unqualified products need to be analyzed and the causes traced.

- Continuous improvement: By analyzing and summarizing quality problems that arise during the procurement process, we will identify the root causes and take corresponding improvement measures. At the same time, quality control technology is regularly reviewed and updated to adapt to changing market needs and technological developments.

- Personnel training and awareness raising: Strengthen the training and awareness raising of procurement personnel and quality inspection personnel, so that they can fully realize the importance of procurement quality control and improve quality awareness and operational skills.

- Preventive maintenance and upkeep: Perform regular preventive maintenance and upkeep on quality inspection equipment to ensure the normal operation and use of the equipment. At the same time, the maintenance and upkeep process should be recorded and tracked to ensure the reliability and stability of the equipment.

- Green and environmentally friendly procurement: Consider environmental protection factors during the procurement process, give priority to component suppliers and products that meet environmental standards and quality requirements, and promote the development of green and environmentally friendly procurement.

- Information management system application: Use the information management system to comprehensively manage the procurement process and realize functions such as information sharing, process optimization, and data statistics and analysis. Improve procurement efficiency and quality control levels through system automation and intelligent reminders.

- Supply chain collaboration: Strengthen communication and collaboration with suppliers to achieve supply chain synergy. Improve the reliability and stability of the supply chain through information sharing, real-time feedback and joint problem solving.

- International quality standards and certification: Establish corresponding quality control systems and quality assurance measures in accordance with international quality standards and certification requirements. Improve the international competitiveness and market share of products through the acquisition of international quality standards and certifications.

Electronic component procurement summary

Electronic component procurement quality control technology is an important means to ensure the quality and reliability of electronic products. In practical applications, the corresponding quality control technology should be selected and applied based on specific needs and actual conditions.

In the future, with the continuous development of the electronics industry, the types and performances of electronic components will become more diversified, and the requirements for quality control technology will also become higher and higher. Therefore, it is necessary to continuously update and improve the quality control technology system, improve quality control levels and technological innovation capabilities, to adapt to changing market demands and technological development.

At the same time, exchanges and cooperation with international advanced enterprises should be strengthened, and international advanced quality control technologies and experiences should be absorbed and used to promote the sustainable development and innovation progress of my country’s electronic component procurement quality control technology.

Frequently Asked Questions

Electronic component procurement quality control technology refers to the quality inspection, testing and control of purchased electronic components through a series of technologies and means to ensure that they meet design requirements and reliability standards.

Quality control techniques include but are not limited to appearance inspection, performance testing, reliability and life evaluation, etc.

Appearance inspection is one of the most basic procurement quality control techniques. Through inspection of appearance dimensions, surface quality, marking and packaging, a preliminary judgment is made as to whether the components meet the requirements.

Performance testing is an important means to evaluate the function and performance of components. Through testing, it can be determined whether the electrical parameters, frequency characteristics, temperature characteristics, etc. of the components meet the design requirements. Performance testing is generally performed using automatic testing equipment, and corresponding testing specifications and standards need to be formulated.

Reliability and life assessment is a test of the long-term stability of components. The life and reliability of components are analyzed through accelerated aging tests, life tests, etc. This process needs to be carried out under specific environmental conditions, such as high temperature, low temperature, high humidity, etc., to accelerate the aging process of components.

Establishing a complete quality assurance system is the key to ensuring the quality of purchased components. The quality assurance system should include supplier selection and evaluation, procurement process control, inspection and testing, handling of non-conforming products, etc., and the system needs to be reviewed and updated regularly.

The application of quality control technology in practice includes supplier selection and evaluation, inspection and testing plan formulation, handling of non-conforming products, continuous improvement, personnel training and awareness raising, etc. In addition, preventive maintenance and upkeep, green and environmentally friendly procurement, information management system applications, supply chain collaboration, etc. are also important application directions.