Electronic component accelerated life testing technology is a test method that accelerates component failure by applying stress beyond the normal range, aiming to evaluate the life and reliability of components in a short time.

Introduction

With the rapid development of science and technology, electronic components are increasingly used in various fields, such as aerospace, medical equipment, communication systems, etc.

However, the reliability issues of electronic components have also become prominent. For some key components, their lifespan and reliability directly affect the stability and safety of the entire system.

Therefore, how to conduct effective life tests and quickly evaluate the life and reliability of electronic components has become the focus of the industry. This article will conduct a detailed analysis and discussion of accelerated life testing technology for electronic components.

Basic concepts of accelerated life testing of electronic components

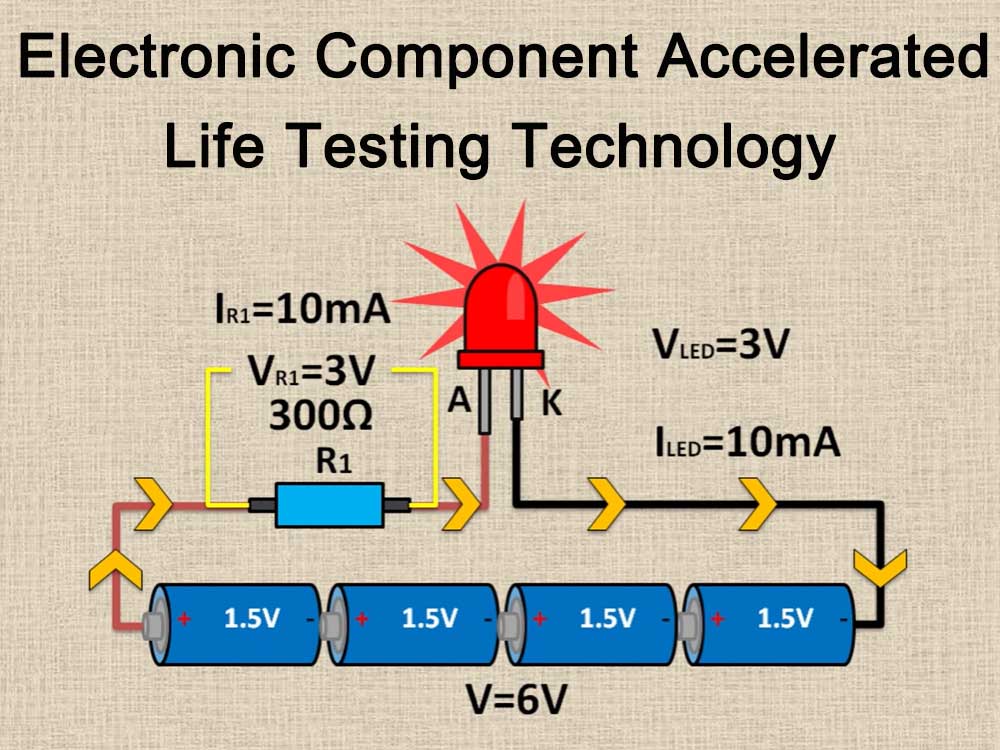

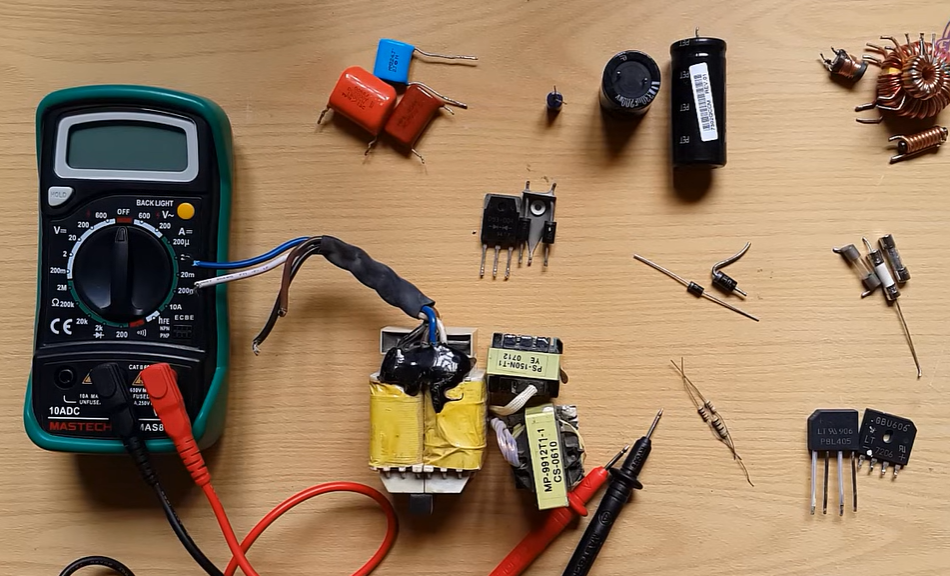

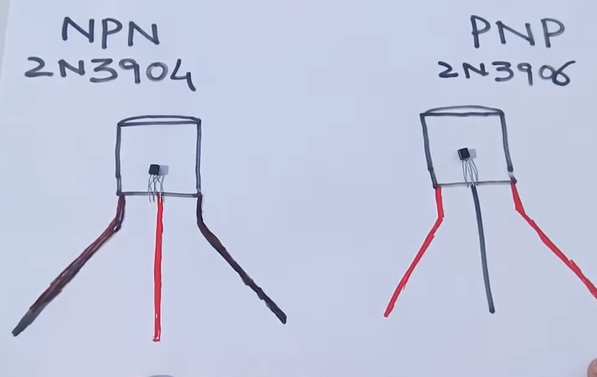

Accelerated Life Testing (ALT) of electronic components is a testing method that accelerates the failure of components by applying stress beyond the normal operating range, such as voltage, current, temperature, etc. Through accelerated life testing, the life and reliability of components can be evaluated in a short period of time, providing a basis for product design, production and quality control.

Test principle

The principle of accelerated life testing is based on the “stress-life” relationship. Under a certain stress, the life of electronic components shows a certain distribution pattern.

By applying stress beyond the normal operating range, the life of a component can be shortened and its failure accelerated. In this way, the life and reliability of components can be evaluated in a shorter period of time.

Experiment method

- Constant stress accelerated life test: During the test, the applied stress remains constant. This method is simple and easy to implement, but the disadvantage is that the test results may be significantly different from the failure mode under actual use conditions.

- Step stress accelerated life test: During the test, the stress gradually increases until it reaches the preset failure criterion. This method can more realistically simulate stress changes under actual use conditions, but the test cycle is longer.

- Sequential stress accelerated life test: During the test, the stress increases in a linear or non-linear manner. In this way, the life and reliability of components can be evaluated in a shorter period of time.

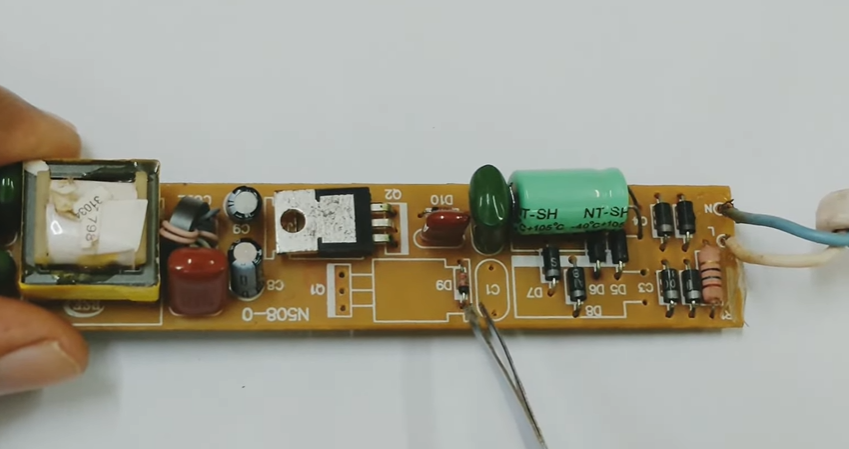

- Accelerated degradation test: By periodically applying accelerated stress loading to electronic components, observe their performance degradation and predict their life and reliability under normal stress. This method needs to be carried out with online monitoring equipment.

Implementation steps of accelerated life testing of electronic components

- Determine the purpose of the test: Make it clear whether the goal of the test is to evaluate the life and reliability of the components or to improve the design of the product.

- Select the test method: Select the appropriate accelerated life test method according to the actual situation.

- Determine the acceleration factor: Select the appropriate acceleration factor (such as voltage, current, temperature, etc.) based on the characteristics of the component and actual usage conditions.

- Develop a test plan: including the number of samples to be tested, loading methods, test methods, data records, etc.

- Carry out the test: Carry out the accelerated life test according to the test plan.

- Data processing and analysis: Process and analyze test data to evaluate the life and reliability of components.

- Conclusions and suggestions: Draw conclusions based on the test results and make suggestions for improving product design and production processes.

Limitations of accelerated life testing of electronic components

Although accelerated life testing can evaluate the life and reliability of components in a shorter period of time, there are still some limitations:

- Difficulty in selecting acceleration factors: Different acceleration factors may have different effects on the failure modes and mechanisms of components. Selecting an appropriate acceleration factor is a challenging task.

- Extrapolation of test results: Since the accelerated life test is conducted under stress beyond the normal operating range, the reliability of the extrapolation of the test results to actual use conditions needs to be handled with caution.

- Insufficient representativeness of samples: Since accelerated life testing requires a large number of samples and time, it is sometimes difficult to ensure the representativeness of the samples, which may have a certain impact on the test results.

- High cost: Accelerated life testing requires professional equipment and manpower investment, as well as a large number of samples and time, so the cost is high.

Summary and prospects of accelerated life testing technology for electronic components

Accelerated life testing technology for electronic components is an important reliability assessment method that can quickly evaluate the life and reliability of components and provide a basis for product design, production and quality control. Although there are certain limitations, this technology still has high practical value in some specific situations.

In the future, with the continuous advancement of technology and the increase in application demand, the accelerated life testing technology of electronic components is expected to be further developed and improved. For example, the accuracy and reliability of this technology can be further improved by improving the acceleration factor selection method, optimizing the test plan, and improving test efficiency.

At the same time, with the development of artificial intelligence and machine learning technologies, these technologies can be used to conduct in-depth analysis and mining of accelerated life test data to gain a more comprehensive understanding of the performance and reliability of electronic components. In addition, other evaluation methods such as physical analysis and chemical analysis can be combined to further reveal the mechanism and causes of electronic component failure, and provide more targeted suggestions and solutions for its reliability design and optimization.

FAQs

Accelerated life testing of electronic components is a testing method that accelerates component failure by applying stress beyond the normal operating range, such as voltage, current, temperature, etc. Through accelerated life testing, the life and reliability of components can be evaluated in a short period of time, providing a basis for product design, production and quality control.

The purpose of accelerated life testing of electronic components is to evaluate the life and reliability of components and improve product design. Through accelerated life testing, weak links and reliability issues of components can be quickly determined, providing a basis for product optimization and improvement.

Choosing the appropriate acceleration factor is the key to accelerated life testing of electronic components. Common acceleration factors include voltage, current, temperature, etc. When selecting an acceleration factor, its impact on component failure modes and mechanisms, as well as stress levels under actual use conditions, should be considered. At the same time, the selection of acceleration factors should also consider test cost and operability.

The number of test samples should be determined based on factors such as test purpose, test time and resources. Too few samples may lead to inaccurate results, while too many samples may increase the cost and time of the test. It is recommended to make a reasonable selection based on the actual situation and consider the representativeness and difference of the sample.

Accelerated life test data should be statistically analyzed and processed to evaluate component life and reliability. Common statistical analysis methods include probability distribution fitting, life test data analysis, reliability assessment, etc. Through data analysis, the life distribution, failure modes and reliability indicators of components can be determined.

Accelerated life test results should be interpreted based on actual conditions. Test results can provide information on the life and reliability of components, but it is necessary to pay attention to the difference between test conditions and actual use conditions. In addition, abnormal results or results that do not match expectations require in-depth analysis and explanation.

The application of accelerated life test results should be based on specific needs. The test results can be used to improve product design, production and quality control, and improve the reliability and stability of components. At the same time, accelerated life test results can also be used to evaluate the effectiveness and accuracy of component life prediction models and reliability assessment methods.