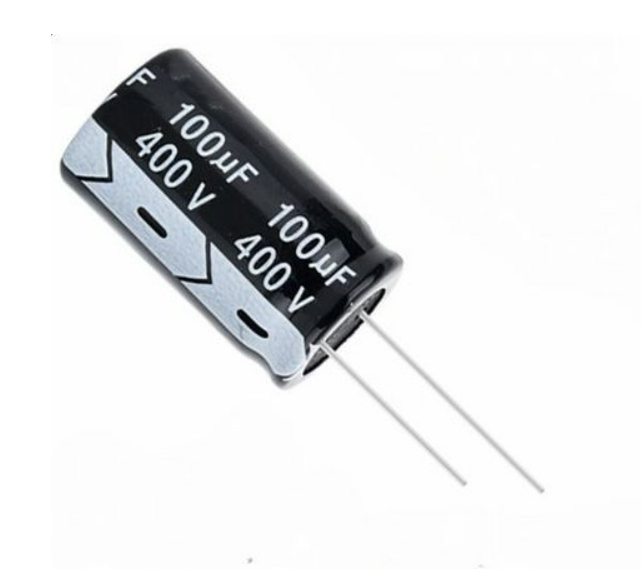

400V100μF plug-in electrolytic capacitor is a commonly used capacitor with high withstand voltage and large capacity.

The following is a detailed introduction to this capacitor:

Introduction to electrolytic capacitors

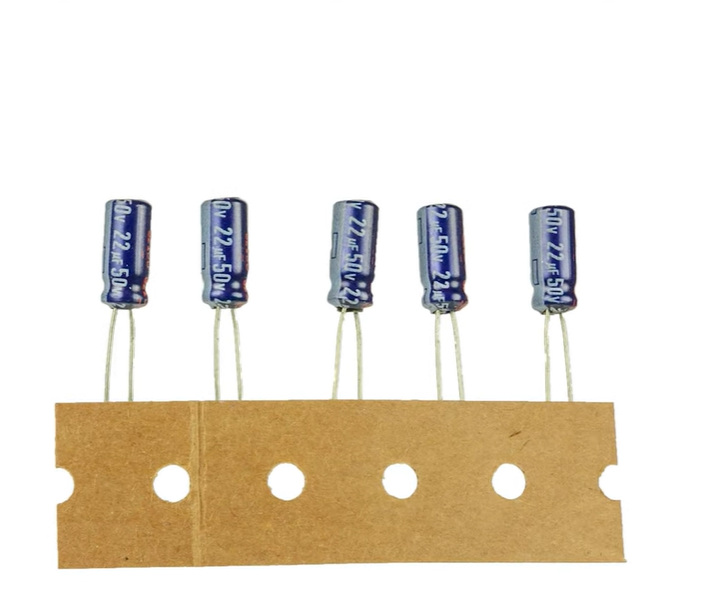

Electrolytic capacitor is a commonly used electronic component. Its working principle is to use electrolyte to generate electrochemical reaction to store charge.

Electrolytic capacitors usually have larger capacity and higher withstand voltage, and are widely used in various electronic equipment and power supplies.

Characteristics of 400V100μF plug-in electrolytic capacitor

- High withstand voltage: 400V withstand voltage can withstand a wide voltage range, ensuring the stability and service life of the capacitor.

- Large capacity: 100μF capacity can store a large amount of charge and is suitable for circuits that require large energy storage.

- Plug-in design: This capacitor adopts plug-in design, which is easy to install and disassemble, and is suitable for the manufacturing and maintenance of various electronic equipment.

- Long life: Electrolytic capacitors usually have a long life and can work stably for a long time.

- Good electrical properties: 400V100μF plug-in electrolytic capacitors have good electrical properties, such as low impedance, low leakage current, etc., and can meet the needs of various circuits.

What is the function of 400v 100uf plug-in electrolytic capacitor

400V 100uF plug-in electrolytic capacitors have many functions in the electronic field:

- Smooth DC voltage: In the DC power supply filter circuit, electrolytic capacitors can smooth the DC voltage, reduce the ripple voltage in the power supply, and provide stable power output.

- Energy storage and balancing current: In the power switching circuit of electronic equipment, electrolytic capacitors play the role of energy storage and balancing current.

- Protection circuit: In some cases, electrolytic capacitors can protect other components when overvoltage or overcurrent occurs in the circuit.

In addition, electrolytic capacitors also help achieve circuit functions such as signal coupling, filtering, and DC isolation.

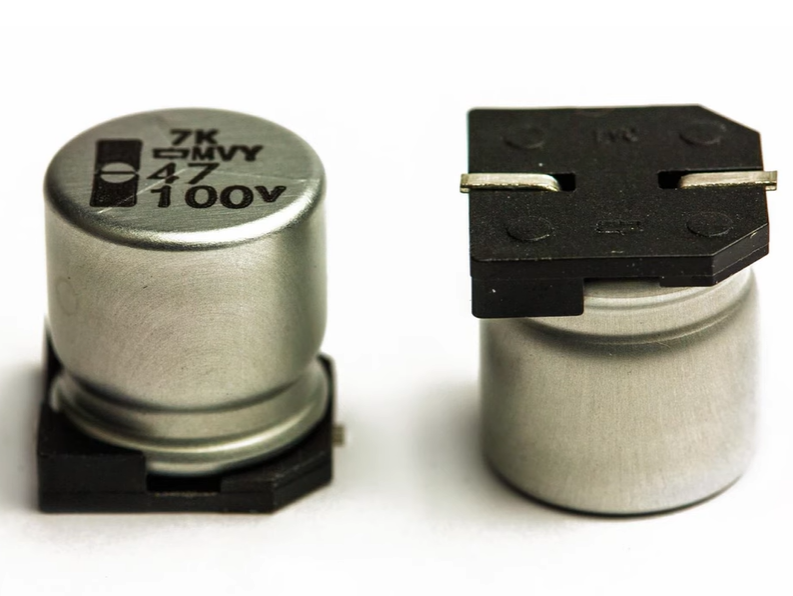

How to install electrolytic capacitor

The installation method of electrolytic capacitors includes the following steps:

- Preparation: Ensure that the selected leaded electrolytic capacitor matches the design requirements, and check whether its parameters and specifications meet the requirements. Prepare a suitable soldering tool such as soldering iron, soldering station and solder extractor.

- Determine the installation location: Determine the installation location of the lead electrolytic capacitor based on the circuit design and layout. Typically, leaded electrolytic capacitors are mounted at specific locations on a circuit board, such as around chip resistors and other electronic components.

- Prepare the circuit board: Clean and prepare the circuit board surface to ensure it is flat, clean and free of impurities. Cleaner or acid-free alcohol can be used to wipe the circuit board surface to ensure soldering quality.

- Install the lead electrolytic capacitor: Insert the leads of the lead electrolytic capacitor into the corresponding solder holes on the circuit board. Make sure the leads are aligned with the solder holes and inserted vertically, avoiding excessive bending or applying excessive force. On the other side of the leads (bottom of the board), use solder and a soldering station to solder. Place hot solder on the contact points of the leads and pads so that it melts and wets enough to form a reliable solder connection. Repeat the above steps to ensure that all leads are soldered correctly and check that the solder joints are even, smooth and not over-soldered.

- Post-welding treatment: After waiting for the welding area to cool down and be fixed, check whether the welding connection of the lead electrolytic capacitor is firm and not loose or short-circuited. A multimeter or other test instrument can be used to verify that the leaded electrolytic capacitor is connected properly.

In addition, when installing electrolytic capacitors, you need to pay attention to the following matters:

- Determine the positive and negative polarity of the electrolytic capacitor and mark it clearly. The markings for the positive and negative terminals are usually printed on the capacitor’s case or marked with two different colored wires, red (+) and black (-). If the positive and negative poles of the electrolytic capacitor are not clearly marked, it is best not to use them to avoid damage to the circuit.

- Select the appropriate electrolytic capacitor according to the requirements of the circuit. Pay attention to parameters such as the capacity, rated voltage, and temperature range of the electrolytic capacitor to ensure that the selected electrolytic capacitor meets the circuit requirements.

- When installing electrolytic capacitors, they should be placed stably to avoid damage from mechanical stress or vibration. At the same time, attention should be paid to the installation height and spacing of electrolytic capacitors to meet heat dissipation and electrical performance requirements.

- When welding electrolytic capacitors, the welding temperature and time should be controlled to avoid overheating damage or false soldering problems to the electrolytic capacitors. At the same time, attention should be paid to the welding quality to ensure that the solder joints are full, smooth and free of burrs.

- When installing electrolytic capacitors, attention should be paid to the leakage of electrolyte. If the electrolyte leaks onto the circuit board, it may cause problems such as short circuits or corrosion. Therefore, when installing electrolytic capacitors, they should be placed in a location where they are not prone to leakage or take appropriate protective measures.

- When using electrolytic capacitors, attention should be paid to their lifespan. The life of electrolytic capacitors is affected by many factors such as temperature, voltage, frequency and usage environment. Therefore, the performance of electrolytic capacitors should be checked regularly during use to find and solve problems in time.

In short, the correct installation method of electrolytic capacitors is crucial to ensure their normal operation and service life.

During the installation process, attention should be paid to details and standardized operations to ensure safe and stable operation of the circuit.

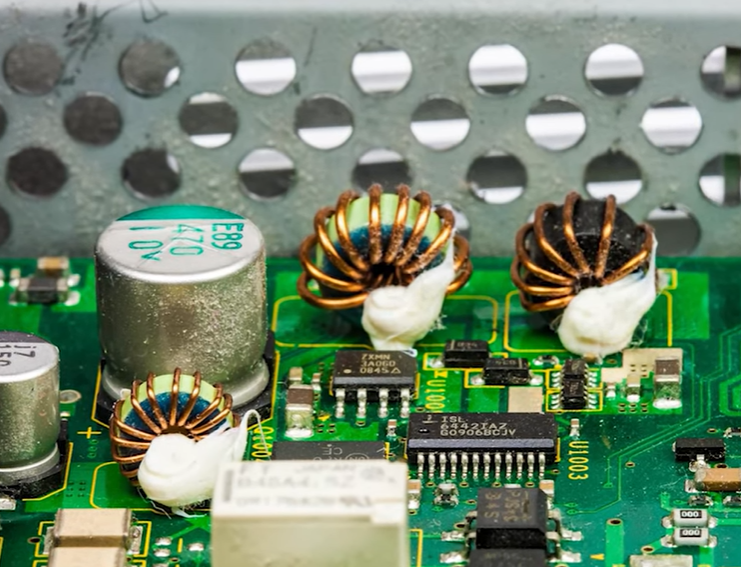

Why electrolytic capacitor used in power supply

Electrolytic capacitors play a key role in power supplies for the following main reasons:

- Filtering effect: Electrolytic capacitors can absorb the ripple current in the circuit and make the output voltage more stable. In the power supply, electrolytic capacitors and other components form a filter network to effectively filter out ripple voltage and improve power quality.

- Energy storage: The energy storage function of electrolytic capacitor allows it to provide a large amount of charge in a short period of time to meet the needs of large current demands in the circuit. For example, in electronic devices such as flashlights and electronic alarm clocks, electrolytic capacitors provide instantaneous power supply.

- Coupling effect: In the process of transmission and amplification of low-frequency signals, electrolytic capacitors are used to couple the static operating points of the front and rear two-stage circuits to prevent mutual influence.

- Maintain voltage: In the oscillation circuit, the electrolytic capacitor can maintain the working voltage of the oscillation circuit, thereby ensuring the normal operation of the oscillation circuit.

To sum up, electrolytic capacitors play a key role in power supplies, helping to improve the stability and reliability of power supplies and extend the service life of equipment.

Application of 400V100μF plug-in electrolytic capacitor

Because 400V100μF plug-in electrolytic capacitors have high withstand voltage and large capacity, they are widely used in various circuits that require higher voltages and larger energy storage. For example, in the fields of power supplies, motor controllers, switching power supplies, etc., this kind of capacitor plays an important role.

Precautions for use

Although the 400V100μF plug-in electrolytic capacitor has a higher withstand voltage and larger capacity, you still need to pay attention to the following points during use:

- Correct installation: When installing electrolytic capacitors, correct installation steps should be followed to ensure that the capacitor can be firmly fixed on the circuit board.

- Avoid overload: When using electrolytic capacitors, overload should be avoided to avoid damage to the capacitor.

- Pay attention to temperature: The operating temperature of electrolytic capacitors should be kept within an appropriate range. Too high or too low temperatures may affect the performance and service life of the capacitor.

- Regular inspection: During use, the performance of the electrolytic capacitor should be checked regularly. If any abnormality is found, it should be dealt with in time.

- Correct replacement: When replacing an electrolytic capacitor, a model with the same or similar specifications as the original capacitor should be selected for replacement to ensure the normal operation of the circuit.

400v100uf plug-in electrolytic capacitor 18*30 specifications and parameters

Product model: 400v100uf 18*30

Specifications: 400v100uf 18*30

Brand: PAGOODA

Unit price: 0.02 yuan/piece (RMB)

Total supply: 100,000 pieces MOQ: 4,000 pieces

Valid until: 2024 (contact the electronic component manufacturer for details)

Ripple current @ low frequency: 100Hz

Ripple current @ high frequency: 1000Hz

Capacitance: 100uf

Voltage: 400v

Volume: 18*30

Tolerance: 20%

Working temperature range: -40+105℃

Lead spacing: 7.5

Application areas: new energy vehicles

Impedance: Standard

Lead spacing: 7.5

Size:18*30

Height – Installation (maximum): 30

Installation type: straight plug

Application areas: new energy vehicles

In order to avoid explosion accidents of electrolytic capacitors, the following measures are taken to address the most basic causes of explosions of electrolytic capacitors.

- Design the withstand voltage of the electrolytic capacitor to be high enough.

- Choose high-frequency electrolytic capacitors in situations with large ripples. If possible, connect a capacitor as large as possible with good high-frequency characteristics in parallel with the electrolytic capacitor, such as a monolithic capacitor.

- Strictly avoid reverse polarity of electrolytic capacitors.

How to contact the 400v100uf plug-in electrolytic capacitor manufacturer

In China, there are many manufacturers that produce 400V100μF plug-in electrolytic capacitors, including Dongguan Kate Capacitor Co., Ltd., Shenzhen Baoan District Shajing Yongxingtai Electronics Business Department, Dongguan Caiduo Electronics Co., Ltd., etc.

These manufacturers all provide production and sales services for electrolytic capacitors, and have a certain degree of popularity and credibility in the domestic market.

To contact these manufacturers, you can use the following methods:

- Search engine: You can use a search engine to search for the contact information of these manufacturers. For example, enter the name and address of the manufacturer in a search engine such as Baidu or Google, and then find the relevant contact information.

- Industry associations: The contact information of these manufacturers can be obtained through relevant industry associations. Industry associations usually include the contact information of member companies, including the contact information of electrolytic capacitor manufacturers.

- Exhibitions: You can obtain the contact information of these manufacturers by participating in relevant exhibitions. At exhibitions, these manufacturers usually display their products and technologies and provide contact information to visitors.

- Direct contact: You can contact these manufacturers directly and ask for their contact information. These manufacturers usually publish their contact information on their websites or promotional materials, and you can contact them by email or phone.

In short, to contact the 400V100μF plug-in electrolytic capacitor manufacturers in China, you can find and contact them in a variety of ways.

When choosing a manufacturer, it is recommended to understand the manufacturer’s product quality, price, after-sales service and other information in order to make a more appropriate choice. If you need please contact us, we are a global wholesaler and supplier of electronic components.

Summarize

400V100μF plug-in electrolytic capacitor is a commonly used electronic component with high withstand voltage and large capacity. It is suitable for various circuits that require higher voltage and larger energy storage.

During use, attention should be paid to correct installation, avoiding overloading, paying attention to temperature, regular inspection and correct replacement to ensure the performance and life of electrolytic capacitors.

400v100uf plug-in electrolytic capacitor FAQs

When selecting a 400V100uF plug-in electrolytic capacitor, you need to consider the following factors: whether the capacitance and voltage meet the circuit requirements; whether the size is suitable for the installation space; whether the brand and price meet the budget. In addition, it is also necessary to pay attention to parameters such as the dielectric material, temperature characteristics, accuracy and stability of the electrolytic capacitor to ensure that the selected electrolytic capacitor can meet the actual application needs.

The parameters of 400V100uF plug-in electrolytic capacitor include capacitance, voltage and size. Among them, the capacitance is 100uF and the voltage is 400V. May come in a variety of sizes, depending on manufacturer and use.

The price of 400V100uF plug-in electrolytic capacitors varies depending on brand, quality and specifications. Generally speaking, high-quality brand products are more expensive, but their performance is stable and reliable and can guarantee long-term use. At the same time, the prices of electrolytic capacitors of different specifications are also different. The larger the size, the higher the price.

400V100uF plug-in electrolytic capacitors are used in a wide range of applications, including power supplies, electronic equipment, motors, lighting and other fields. They are widely used in circuits such as power supply filtering, signal coupling, energy storage, and DC isolation.

When installing and using 400V100uF plug-in electrolytic capacitors, you need to pay attention to the following points: First, make sure that the voltage and capacitance of the electrolytic capacitor meet the circuit requirements and cannot exceed its rating; secondly, choose a suitable installation location to avoid high temperature, The influence of humidity, mechanical force and other adverse factors; finally, pay attention to the positive and negative polarity of the electrolytic capacitor, and do not connect it reversely. During use, it is also necessary to regularly check the performance of electrolytic capacitors to find and solve problems in time.