Failure analysis and application of electronic components is a key link to ensure the reliability and life of electronic products.

By analyzing failed electronic components, we can gain an in-depth understanding of their failure mechanisms, and then take effective measures to improve the reliability and stability of the components. This article will introduce in detail the common methods, application fields and importance of electronic component failure analysis.

Failure Analysis Methods for Electronic Components

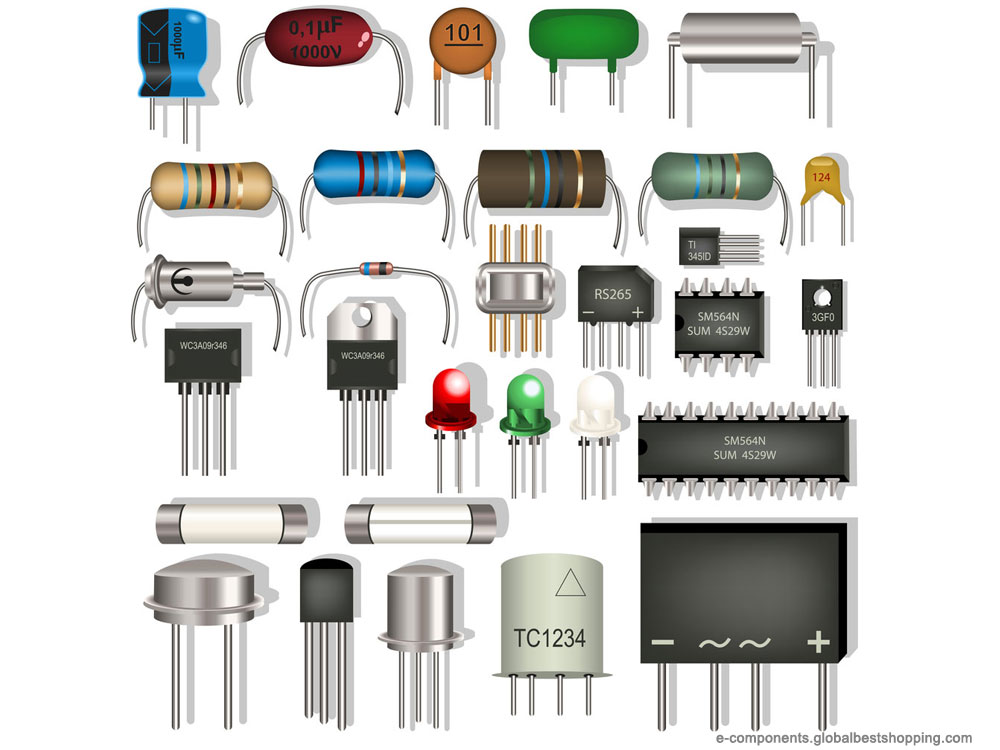

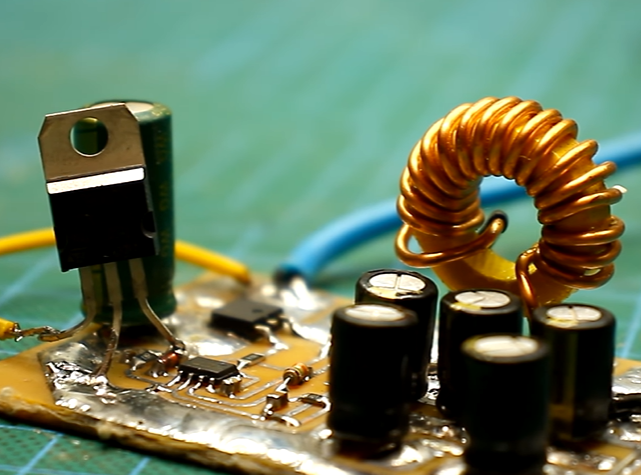

- Appearance inspection: Check the appearance of electronic components visually or under a microscope to see if there is any obvious physical damage or abnormality, such as fracture, deformation, ablation, etc.

- Electrical performance testing: Conduct electrical performance testing on electronic components, such as resistance, capacitance, inductance, etc., to detect whether they meet the design requirements.

- Structural analysis: Use X-ray, scanning electron microscope (SEM), energy dispersive analysis (EDS) and other means to conduct structural analysis of electronic components to understand their internal structure and material composition.

- Chemical analysis: Conduct chemical composition analysis of electronic components through chemical dissolution, spectral analysis, mass spectrometry and other methods to determine their chemical composition and impurity content.

- Environmental testing: Electronic components are tested in harsh environments such as high temperature, low temperature, humidity, salt spray, etc. to evaluate their adaptability and reliability.

- Failure mode and effect analysis (FMEA): Conduct failure mode and effect analysis on failed electronic components to determine the failure mode, failure cause and failure consequences, and propose corresponding improvement measures.

Electronic component failure analysis application areas

- Aerospace field: In the aerospace field, the failure of electronic components may lead to major accidents and catastrophic consequences. Therefore, failure analysis of electronic components is crucial to ensure the safety and reliability of spacecraft.

- Military field: A large number of electronic components are used in military equipment, and their reliability is directly related to the success or failure of military operations. Through failure analysis, the weak links of electronic components in military equipment can be found and their reliability can be improved.

- Industrial field: In equipment in industrial control, electric power, communications and other fields, the reliability of electronic components directly affects the normal operation of the equipment. Through failure analysis, the design and manufacturing process of electronic components can be optimized and the stability and reliability of the equipment can be improved.

- Consumer electronics field: Consumer electronics products such as mobile phones, TVs, computers, etc. use a large number of electronic components. The quality and user experience of these products are closely related to the reliability of electronic components. Through failure analysis, potential problems in the product can be found and product quality and user satisfaction can be improved.

The Importance of Failure Analysis of Electronic Components

- Improve product quality: By analyzing failed electronic components, we can identify problems in the design, manufacturing or use process, and optimize product design, manufacturing processes and material selection, thereby improving product quality and reliability.

- Extend product life: By analyzing failed electronic components, understanding their failure mechanisms and influencing factors, and taking corresponding improvement measures, the life and stability of the product can be improved.

- Reduce maintenance costs: By analyzing failed electronic components, we can quickly and accurately determine the cause of the failure and provide guidance and basis for maintenance, which can shorten the maintenance cycle and reduce maintenance costs.

- Improve safety: In some key fields such as aerospace, military equipment, etc., the failure of electronic components may cause serious safety problems. By analyzing failed electronic components, potential safety hazards can be discovered in time and effective measures can be taken to avoid accidents.

- Promote technological progress: Through in-depth analysis of failed electronic components, we can understand their shortcomings in performance and reliability and promote the progress and development of related technologies. At the same time, failure analysis can also provide useful reference for the development and application of new materials.

In short, failure analysis of electronic components is of great significance in ensuring the reliability and life of electronic products.

By analyzing failed electronic components, product design, manufacturing processes and material selection can be optimized, product quality and reliability can be improved, product life can be extended, maintenance costs can be reduced, safety can be improved and technological progress can be promoted.

Electronic component technology manufacturers

E-components is a wholesaler and supplier of electronic components in China. In the field of electronic component failure analysis, there are many well-known manufacturers and technology providers, and E-components is one of them.

Of course, there are other electronic component failure analysis manufacturers; for example, the US JEDEC is an international organization dedicated to formulating and promoting electronic industry standards.

In addition, there are many professional failure analysis institutions, such as Cypress Semiconductor in the United States and Heraeus in Germany.

These institutions have rich experience and advanced technology in the field of electronic component failure analysis, and can provide customers with accurate and reliable analysis services.

FAQs on Failure Analysis and Application of Electronic Components

Electronic component failure analysis is a technical process by which the causes and mechanisms of electronic component failure can be determined. This involves conducting a series of tests and inspections on failed electronic components to collect failure information and analyze it to identify the mode and root cause of the failure.

The purpose of electronic component failure analysis is to improve the reliability and safety of electronic products. Through failure analysis, the cause and mechanism of the failure can be found, so that effective measures can be taken to prevent the recurrence of similar failures and improve the reliability and stability of electronic products.

There are many reasons for the failure of electronic components, including manufacturing defects, overload or voltage breakdown, excessive temperature, excessive humidity, radiation, etc. In addition, incorrect use and maintenance can also lead to the failure of electronic components.

Failure analysis of electronic components usually includes steps such as visual inspection, electrical performance testing, non-destructive testing and destructive testing. Appearance inspection can find obvious defects or abnormalities; electrical performance testing can detect the electrical performance of failed electronic components; non-destructive testing can check the structure of electronic components through X-ray or ultrasonic methods; destructive testing can further determine Causes and mechanisms of failure.

Electronic component failure analysis has applications in many fields, such as electronic product manufacturing, quality control, product maintenance, and reliability engineering. In electronic product manufacturing, failure analysis can ensure product quality and reliability; in quality control, failure analysis can be used to detect problems in the production process; in product maintenance, failure analysis can help identify and repair faulty components; In reliability engineering, failure analysis can be used to predict and evaluate product life and reliability.

The basic steps of electronic component failure analysis include collection of failure samples, visual inspection, electrical performance testing, structural analysis, chemical composition analysis, environmental testing and failure mode and effect analysis.

Failure analysis of electronic components is widely used in aerospace, military, industry, consumer electronics and other fields to ensure the reliability and life of electronic products.

The importance of electronic component failure analysis lies in improving product quality, extending product life, reducing maintenance costs, improving safety and promoting technological progress. By analyzing failed electronic components, we can discover problems in the design, manufacturing and use processes, optimize product design, manufacturing processes and material selection, and improve product reliability and stability. At the same time, failure analysis can also provide useful reference for the development and application of new materials and promote the progress and development of related technologies.

Visual inspection of electronic components can be performed by visual or microscopic inspection. The inspection content includes whether there are cracks, deformation, ablation, discoloration and other abnormal phenomena in the appearance of the components, as well as whether the solder joints are intact and whether the markings are clear, etc.

The electrical performance testing of electronic components includes testing their resistance, capacitance, inductance, voltage, current and other parameters under different conditions to detect whether they meet the design requirements. Commonly used test instruments include multimeters, oscilloscopes, signal generators, etc.

Structural analysis of electronic components can be carried out through X-ray, scanning electron microscope (SEM), energy dispersive analysis (EDS) and other means. These methods can be used to observe the internal structure of components and understand their material composition and element distribution.

The chemical composition analysis of electronic components can be carried out through chemical dissolution, spectral analysis, mass spectrometry and other methods. These methods can be used to determine the chemical composition and impurity content of components, which are very helpful in identifying the quality and reliability of raw materials.

Environmental testing of electronic components includes high temperature, low temperature, humidity, salt spray and other tests to evaluate their adaptability and reliability under various environmental conditions. During the test process, it is necessary to strictly control the test conditions and observe the performance and appearance changes of the components.