Selecting and purchasing electronic components requires full consideration of factors such as requirements, specifications, performance, cost, availability and scalability.

First, it is necessary to clarify the project requirements and determine the required circuit board type, functions and specifications. Secondly, compare the specifications and performance between different products and select the electronic components that best suit the project needs.

At the same time, consider cost and availability, and look for reliable suppliers and reasonably priced products. Additionally, focus on scalability to prepare for future expansion needs. Finally, verification and testing are performed to ensure that the selected electronic components meet the project application requirements.

Why should you choose an electronic component supplier or manufacturer?

The main reasons for choosing electronic component suppliers or manufacturers are as follows:

Ensure product quality

Electronic component suppliers or manufacturers need to ensure the quality of their products when choosing. Because these components are the basis of electronic equipment, their quality directly affects the quality and performance of the entire electronic equipment. Therefore, choosing a supplier with a good reputation and track record can greatly reduce the risk of purchasing low-quality components.

Stable supply capability

Some small suppliers may not be able to meet the demand for large-volume purchases, while some large suppliers may have risks of delays in quality control and delivery time. Therefore, it is more reliable and safe to choose a supplier with stability and strong production capacity.

Get technical support

When selecting an electronic component supplier or manufacturer, you need to consider whether it can provide the necessary technical support and after-sales service. When problems occur with electronic components, being able to obtain technical support and solve the problem in a timely manner can greatly reduce production costs and time costs.

Optimize inventory management

Choosing a supplier that can provide timely delivery and accurate inventory management can help manufacturers optimize inventory management and avoid overstocking or out-of-stock situations, thereby reducing production costs and time costs.

Reduce procurement costs

When choosing an electronic component supplier or manufacturer, you need to consider its price and quality. Choosing suppliers with reasonable prices and reliable quality can help manufacturers reduce procurement costs and improve product competitiveness.

It is very important to select electronic component suppliers or manufacturers, which can effectively guarantee product quality, supply stability, obtain technical support, optimize inventory management, and reduce procurement costs.

How to choose and buy electronic components?

Selecting and purchasing electronic components requires following certain steps and considerations. Here are some suggestions:

Clarify needs

First, you need to clarify the project requirements, including the required circuit board type, functions and specifications. This will help you choose the right electronic components.

Make specs and performance comparisons

When selecting electronic components, compare specifications and performance between different products to select the electronic components that best suit your project needs.

Consider cost and availability

When selecting electronic components, consider cost and availability. Look for products with reliable suppliers and reasonable prices.

Validation and testing

After electronic components are selected, they are verified and tested to ensure they meet the project requirements. This will help you ensure that the electronic components you choose meet your application requirements.

Choose a reputable supplier

Choosing a supplier with a good reputation can ensure the quality of components and service. You can refer to the supplier’s qualifications, historical performance, customer reviews and other information to evaluate its credibility.

Understand the supplier’s after-sales service

Choosing a supplier that can provide timely and effective after-sales service can help you better solve the problems encountered during procurement and use.

Consider delivery time and delivery method

When purchasing electronic components, consider whether the delivery time and delivery method meet the needs of the project. At the same time, attention should be paid to the timeliness and stability of delivery.

Do a good job in inventory management

Reasonable inventory management can avoid overstocking and out-of-stock components, thereby reducing costs and improving production efficiency.

Pay attention to environmental protection and sustainable development

When choosing electronic components, consider environmental protection and sustainability factors. Choosing products with low energy consumption and low pollution can help reduce environmental load and promote sustainable development.

Selecting and purchasing electronic components requires careful evaluation of multiple factors such as demand, specifications, performance, cost, availability, supplier reputation, after-sales service, etc., to ensure the procurement of electronic components that meet project requirements and reduce procurement risks.

What should you pay attention to when purchasing electronic components?

When purchasing electronic components, you need to pay attention to the following points:

Specifications and quality

When purchasing electronic components, pay attention to compliance with specifications and quality. There may be differences between different brands and models of electronic components, so make sure the electronic components you purchase meet the needs and specifications of your project.

Supplier reputation and qualifications

Choosing suppliers with good reputation and qualifications can ensure the quality and service of electronic components. Pay attention to the supplier’s qualifications, historical performance, customer reviews and other information, and choose reliable suppliers.

cost and price

When purchasing electronic components, cost and price factors should be considered. Prices may vary between different suppliers and brands, so choose products that are reasonably priced and of reliable quality.

Delivery time and stability

When purchasing electronic components, consider delivery time and the stability of the delivery method. It is necessary to ensure that the required electronic components can be obtained in time and maintain the stability of supply.

After-sales service and technical support

Choosing a supplier that can provide timely and effective after-sales service and technical support can help solve problems encountered during procurement and use.

Inventory management and environmental factors

Reasonable inventory management can avoid overstocking and out-of-stock components, thereby reducing costs and improving production efficiency. At the same time, when selecting electronic components, environmental protection and sustainable development factors must be considered. Choosing products with low energy consumption and low pollution can help reduce environmental load and promote sustainable development.

The procurement of electronic components requires careful evaluation of multiple factors such as demand, specifications, quality, cost, supplier reputation, delivery time, after-sales service and technical support to ensure the procurement of electronic components that meet project requirements and reduce procurement risks.

What knowledge and skills are needed to purchase electronic components?

Procurement of electronic components requires the following knowledge and skills:

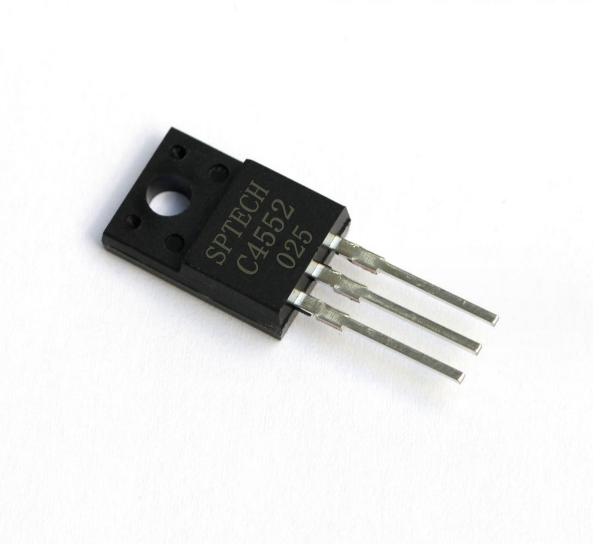

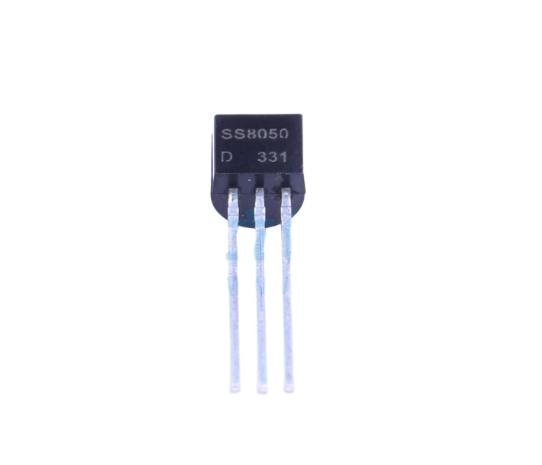

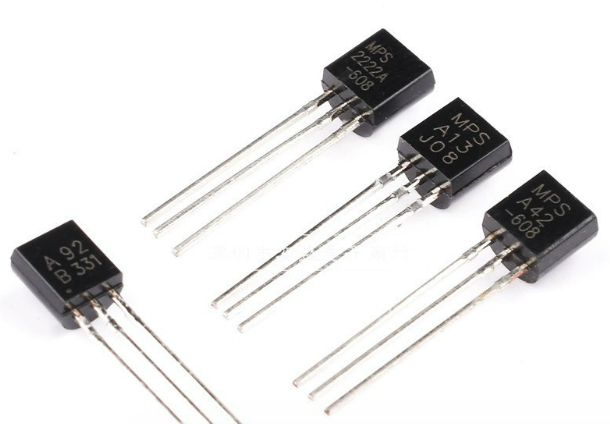

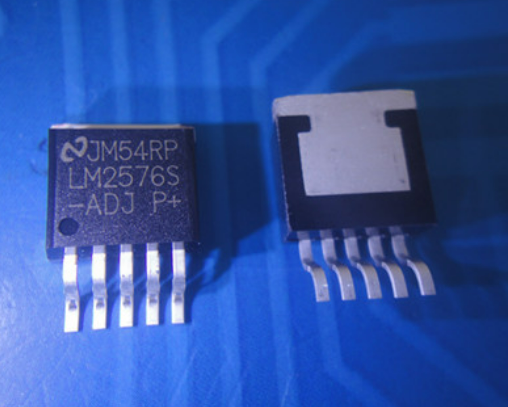

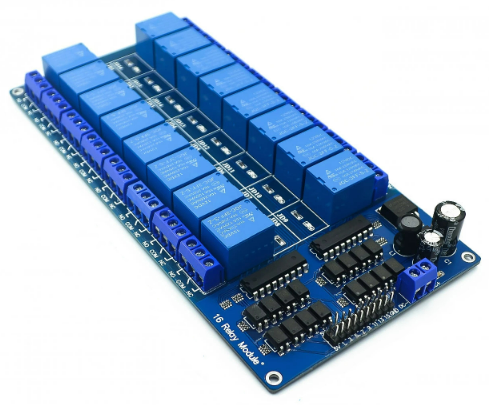

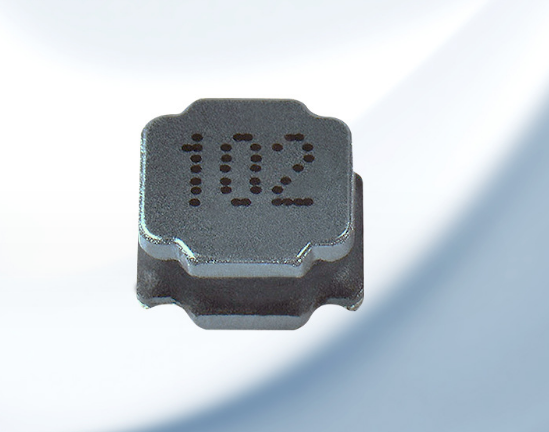

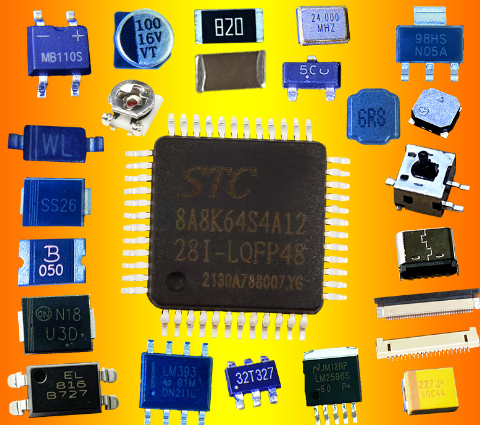

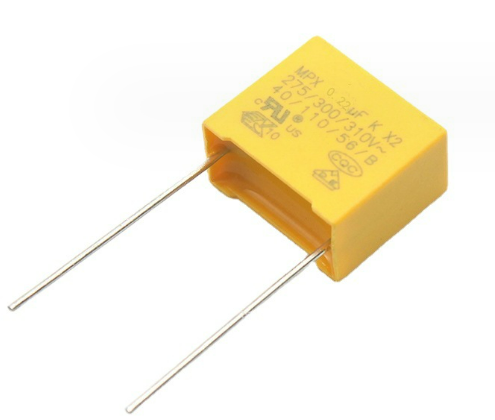

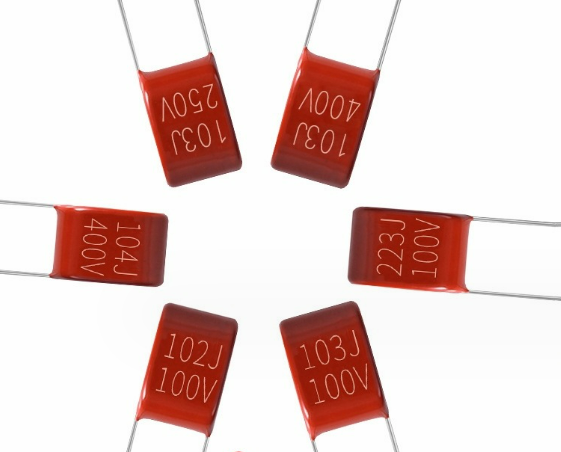

- Basic knowledge of electronic components: Understand the types, characteristics, functions and applications of electronic components, including resistors, capacitors, inductors, diodes, transistors, integrated circuits, etc.

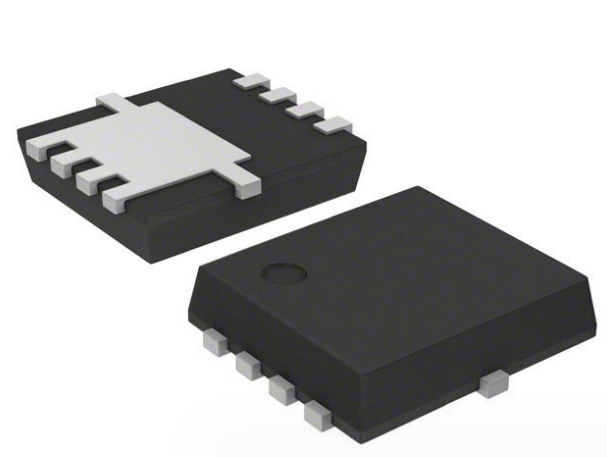

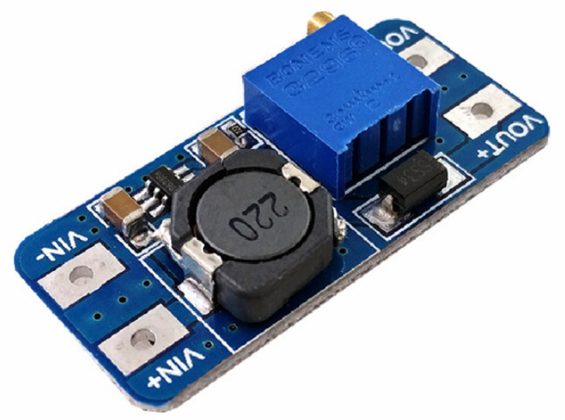

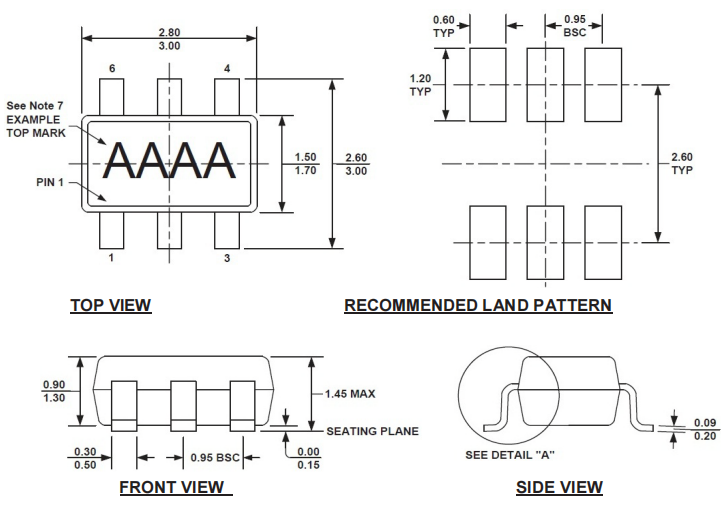

- Specifications and parameters of electronic components: Master the specifications and parameters of electronic components, such as rated voltage, rated current, packaging form, temperature characteristics, etc., in order to correctly select and purchase appropriate components.

- Supply chain management: Understand the basic principles and processes of supply chain management, including supplier selection, supplier quality management, supply chain risk management, etc., to ensure the stability and reliability of the supply chain.

- Procurement skills: Master procurement negotiation and price bargaining skills in order to effectively communicate and negotiate with suppliers during the procurement process to obtain better prices and services.

- Quality testing and evaluation: Understand the methods and tools of quality testing and evaluation in order to conduct quality testing and evaluation of purchased electronic components to ensure that they meet the needs and specifications of the project.

- Inventory management: Master the principles and methods of inventory management, including the formulation of inventory plans, inventory control, inventory counting, etc., in order to better manage inventory and avoid the backlog and shortage of components.

- Knowledge of laws and regulations: Understand the laws, regulations and standards related to the procurement of electronic components, such as the “Contract Law”, “Product Quality Law”, etc., in order to comply with relevant regulations during the procurement process and protect your own legitimate rights and interests.

In short, electronic component procurement requires a wealth of electronic component knowledge and related skills to ensure that you can correctly select, purchase and manage the required electronic components, while protecting your own interests and the successful implementation of the project.

How to customize electronic component procurement solutions?

Customized electronic component procurement solutions need to start from the following aspects:

Clarify needs and goals

First of all, it is necessary to clarify the needs and goals of purchasing electronic components, including the required types, specifications, quantity and quality requirements, etc. At the same time, you need to understand the specific requirements and time points of the project to provide a basis for customized procurement plans.

Conduct market research and analysis

Conduct research and analysis on the electronic components market to understand the price, quality, performance and supply capabilities of different brands, suppliers and products. Through comparison and analysis, identify competitive suppliers and products that meet project needs.

Evaluate vendors and products

Evaluate selected suppliers and products, including supplier qualifications, reputation, product quality and after-sales service, etc. At the same time, it is necessary to understand the supplier’s commercial terms such as delivery time, price, payment method, etc., in order to provide support for customized procurement plans.

Develop purchasing plan

Develop electronic component procurement plans based on project requirements, market research and analysis, and supplier evaluation results. Including purchase type, specifications, quantity, price, delivery time, payment method and other commercial terms, as well as quality testing and evaluation plans, etc.

Negotiate and negotiate with suppliers

Negotiate and negotiate developed procurement plans with selected suppliers to agree on commercial terms and details. During the negotiation process, focus on key factors such as price, quality, delivery time, and payment methods to ensure an agreement that meets project needs and timelines.

Sign contracts and implement procurement plans

Based on the results of consultation and negotiation, a formal procurement contract is signed with the supplier. The rights and obligations of both parties must be clarified in the contract, including details such as specifications, quantity, price, delivery time, payment method, etc. of electronic components. At the same time, corresponding procurement plans and management mechanisms must be established to ensure the smooth execution of the procurement plan.

Conduct quality testing and assessment

Upon receipt of shipment from suppliers, quality inspection and evaluation of electronic components is performed to ensure compliance with project needs and specifications. If quality problems are discovered, they must be negotiated and resolved with the supplier in a timely manner to ensure the smooth progress of the project.

Summary and feedback

After the procurement is completed, summary and feedback should be carried out in a timely manner, and problems and experiences in the procurement process should be sorted out and summarized to provide reference for future procurement work.

Customized electronic component procurement solutions need to start from demand, conduct market research and analysis, evaluate suppliers and products, formulate procurement plans and negotiate with suppliers, sign contracts and implement procurement plans, and finally conduct quality inspection and evaluation and summarize feedback . This process requires attention to detail and risk management to ensure successful project implementation and reduce procurement risk.

When purchasing electronic components, should you choose suppliers or manufacturers?

In the procurement of electronic components, choosing a supplier or manufacturer mainly depends on the specific needs and circumstances of the procurement. Here are some considerations:

Procurement scale

If your purchase is larger, you can choose to buy directly from the manufacturer to get more competitive prices and volume discounts. If the purchase is smaller, consider purchasing from an authorized dealer or distributor for more convenient purchasing and more timely delivery.

Technical Support

If you need technical support or after-sales service, it may be more advantageous to choose the manufacturer. Manufacturers usually provide more comprehensive technical support and after-sales services to meet customer needs.

Procurement risk

If the electronic components being purchased are specialized or complex, it may be more secure to choose a supplier or manufacturer with relevant experience and expertise. They may have better technical capabilities and quality control capabilities to ensure product quality and performance.

purchase cost

Comprehensive consideration of procurement costs, including product price, transportation costs, tariffs, etc. Different suppliers or manufacturers may offer different quotes and fee structures, so a thorough comparison and analysis is required.

Credibility and reliability

It is important to choose a supplier or manufacturer with good reputation and reliability to ensure that the electronic components purchased meet the expected quality and performance standards and can be delivered on time.

To sum up, in the procurement of electronic components, the selection of suppliers or manufacturers should be weighed and decided based on specific circumstances. Several factors such as procurement scale, technical support, procurement risks, procurement costs, reputation and reliability need to be considered.

What are the essential knowledge points for electronic component buyers?

Essential knowledge points for electronic component buyers include:

Basic knowledge of electronic components

Understand the types, characteristics, functions and applications of various common electronic components, including resistors, capacitors, inductors, diodes, transistors, integrated circuits, etc.

Specifications and parameters of electronic components

Master the specifications and parameters of electronic components, such as rated voltage, rated current, packaging form, temperature characteristics, etc., in order to correctly select and purchase appropriate components.

supply chain management

Understand the basic principles and processes of supply chain management, including supplier selection, supplier quality management, supply chain risk management, etc., to ensure the stability and reliability of the supply chain.

Price and cost management

Understand the price trends and cost structure of the electronic components market and be able to conduct cost analysis and price negotiations to obtain reasonable purchase prices.

Procurement process and contract management

Familiar with the basic knowledge of procurement process and contract management, including demand confirmation, price inquiry, comparative evaluation, contract signing, etc., and be able to reasonably arrange procurement work and manage contract execution.

Supplier management

Understand the basic principles and methods of supplier management, including supplier evaluation, supplier performance management, supplier relationship management, etc., to ensure the stability and reliability of suppliers.

Quality Control

Understand the basic principles and methods of quality management, including quality inspection, quality control, quality improvement, etc., to ensure that purchased electronic components meet quality requirements.

Project management and time management

Have basic project management and time management knowledge and skills, and be able to reasonably arrange the time and resources of the procurement project to ensure the smooth progress of the project.

Communication and coordination skills

Have good communication and coordination skills and be able to communicate and coordinate effectively with suppliers, internal departments and other relevant parties to ensure the smooth progress of procurement work.

Technical learning and updating capabilities

Able to continuously learn and update relevant knowledge and technologies of electronic components to keep up with the development and changes of the industry and improve the efficiency and quality of procurement work.

These knowledge points are not isolated, but need to be applied comprehensively. At the same time, as the industry develops and changes, buyers also need to constantly learn and update their knowledge and skills.

How do PCB assembly factories generally select electronic components?

PCB assembly factories need to consider the following factors when selecting electronic components:

cost

The first thing to consider is the cost of components, including purchase price, transportation costs, tariffs, etc. On the premise of ensuring the quality of components, choosing suppliers with reasonable prices is the key to reducing costs.

Quality

The quality of components directly affects the performance and reliability of the product, so it is crucial to choose components with reliable quality. The quality of components can be ensured by evaluating information such as certification, inspection, and usage history of components.

Delivery time

Factors such as the delivery time of components, production cycle and production plan need to be considered. While ensuring the smooth progress of the production plan, it is also necessary to consider whether the delivery time of components meets the requirements of the production plan.

Supplier reputation

Choosing a reputable supplier can ensure reliability in terms of component quality and delivery time. Reliable suppliers can be selected by evaluating the supplier’s qualifications, historical performance, customer reviews and other information.

Technical Support

Choosing a supplier that can provide timely and effective technical support can help solve problems encountered during the production process and improve production efficiency and quality.

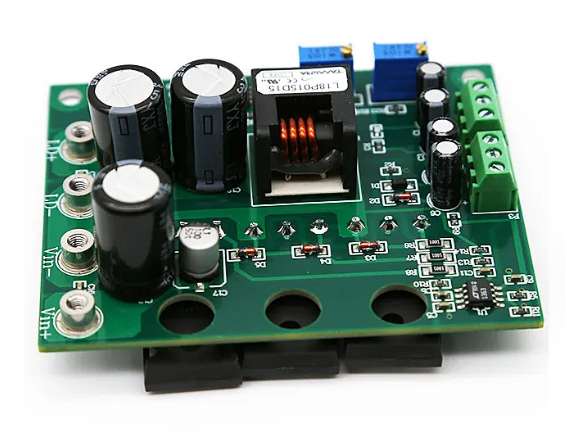

Packaging and Specifications

It is necessary to consider whether the packaging and specifications of the components meet the requirements of the PCB board diagram and whether they meet the requirements of the manufacturing process. At the same time, factors such as the installation and welding difficulty of components need to be considered.

envirnmental factor

The environmental adaptability of components needs to be considered, such as temperature range, humidity, electromagnetic compatibility, etc. These factors have a certain impact on the performance and service life of the product.

When selecting electronic components, PCB assembly factories need to comprehensively consider and analyze based on their own actual conditions and needs to select appropriate suppliers and components to ensure the smooth progress of production and the quality and reliability of products.

Do I need a BOM list for purchasing electronic components?

Electronic component procurement requires a BOM list. The BOM list is an important tool for electronic component procurement. It lists all the materials and components required to manufacture a product, as well as their respective quantities.

In the procurement of electronic components, the BOM list can help procurement personnel clarify the components and their quantities to be purchased, and avoid missing or incorrect procurement. At the same time, the BOM list can also help purchasing personnel estimate product costs and better arrange purchasing plans. Therefore, the BOM list is very important for electronic component procurement.

Is the BOM list important for electronic component procurement?

The BOM list is very important in the procurement of electronic components. The BOM list is a detailed list describing the product composition and required components. It includes the model, specification, quantity and other relevant information of each component. The following is the importance of BOM list in the procurement of electronic components:

- Ensure completeness: The BOM list can ensure the integrity of purchased components and prevent missing or over-purchased components. By carefully checking the BOM list, purchasing personnel can ensure that the purchased components are consistent with product requirements, thereby avoiding production delays and waste caused by missing or over-purchasing.

- Improve efficiency: By using the BOM list, purchasing personnel can handle purchasing matters more efficiently. They can quickly generate purchase orders based on the information in the BOM list and communicate effectively with suppliers, thereby reducing communication costs and error rates.

- Control costs: The BOM list can help purchasing personnel better control costs. By conducting cost analysis on the components in the BOM list, purchasing personnel can select components with higher cost performance, thus reducing the overall procurement cost.

- Quality management: The BOM list can be used as an important reference for quality management. By conducting quality inspections on the components in the BOM list, you can ensure that the purchased components meet quality requirements, thereby improving product quality and reliability.

- Tracking and tracing: The BOM list helps track and trace the source and usage of components. When a problem occurs or repair is required, you can quickly locate the source and replacement of the problematic component by viewing the BOM list, thereby improving the efficiency and quality of after-sales service.

The BOM list plays a vital role in the procurement of electronic components. By using the BOM list, purchasing personnel can ensure the integrity of components, improve efficiency, control costs, manage quality and track and trace, thereby providing strong guarantee for the production and operation of the enterprise.

How do PCB assembly manufacturers store electronic components in warehouses?

When electronic components of PCB assembly manufacturers are stored in warehouses, they need to follow certain specifications and requirements to ensure the quality and reliability of the components. Here are some common storage requirements:

- Classified storage: Classify and store components according to their types, specifications, characteristics, etc. For example, electronic components such as resistors, capacitors, and diodes can be placed in different areas or shelves for easy management and search.

- Label identification: Each component should be labeled, and the label should include the component’s model, specification, quantity and other information. This avoids confusion and incorrect use of components.

- Moisture-proof and dust-proof: Electronic components are easily affected by moisture and dust, so the warehouse should be kept dry, clean, and equipped with measures such as dust removal and moisture-proofing. Some components that are sensitive to humidity should be stored in a dry box or protected with moisture-proof agents.

- Sun protection and high temperature protection: Some electronic components will be affected by sunlight and high temperature, so warehouses should have sun protection measures to prevent direct sunlight from shining on the components. At the same time, the temperature of the warehouse should be controlled within a certain range to avoid damage to components caused by excessive temperatures.

- Fire and explosion prevention: Some electronic components are flammable and explosive, so the warehouse should have fire and explosion prevention measures, such as installing smoke alarms, fire extinguishers, etc.

- Regular inspection: Warehouse managers should regularly inspect electronic components, including quantity, quality, expiration date, etc. Some components that are approaching their expiration date should be processed or replaced in time.

- Record management: Warehouse managers should record and manage the purchase, storage, and delivery of electronic components to facilitate tracking and tracing.

PCB assembly manufacturers need to strictly abide by specifications and requirements when storing electronic components to ensure the quality and reliability of components. At the same time, regular inspections and record management are required to avoid errors and losses.

Detailed steps for purchasing electronic components

The detailed steps for purchasing electronic components usually include the following links:

Clarify purchasing needs

First of all, it is necessary to clarify the model, quantity, quality and other requirements of the components that need to be purchased. This is to ensure that the purchased components meet actual needs and avoid blind purchasing and waste of resources.

Find the right supplier

Find suppliers that meet your procurement needs through search engines, procurement websites, exhibitions, etc. When selecting a supplier, factors such as the supplier’s strength, credibility, and quality assurance need to be considered.

Develop purchasing plan

Develop a detailed procurement plan based on procurement needs and suitable suppliers. The procurement plan usually includes component model, description, quantity, purchase price, delivery time, contact person, contact information, delivery address and other information. This can integrate supplier resources, reduce procurement costs, and improve procurement efficiency.

Initiate an inquiry or quote

Initiate price inquiries to multiple suppliers through email, phone calls, online inquiry, etc., and obtain quotations from each supplier. Compare the price and quality of different suppliers and choose the most suitable one.

signing the contract

Sign electronic component purchase contracts with selected suppliers. The contract should clearly include important terms such as the name, model, quantity, price, delivery method and time, and quality requirements of the purchased items. Signing a contract is conducive to the protection of the rights and interests of both parties and a good start for cooperation. Be sure to ensure that procurement-related regulations, standards, and quality requirements are spelled out in the contract.

Supervise warehouse management

After the purchase is completed, it is necessary to supervise the warehouse purchase and inventory management. Ensure that the storage method, environment, and fire safety of components meet requirements. Avoid the situation of “three days of fishing and two days of drying the net” and handle warehouse management issues in a timely manner.

Check into the database

Usually, purchased electronic components are subject to strict quality control and need to be inspected and stored in the warehouse. Compare the warehousing materials with the purchasing list to confirm that the quality of the materials is correct before warehousing. After passing the acceptance, the items will be put into the warehouse management system and marked, and the inventory changes of items, raw materials and finished products can be tracked at any time.

These steps are the basic process for purchasing electronic components, but they may differ depending on the actual purchasing situation. For example, if the purchase quantity is large or the cooperation is long-term, a bidding or inquiry process may be required; if the purchased components are special or complex, more technical communication and negotiation may be required. Therefore, in actual procurement, the procurement process should be flexibly adjusted and optimized according to specific circumstances.

Best website to purchase electronic components

If you want to purchase electronic components, please contact us. If you want to know more about Electronic Components: Selection and Application Guide pdf document, please contact us and it will be sent to you.