The electronic components and materials required to make LED lights include LED lamp beads, drive circuits, radiators, lampshades, power cords, screws and other fasteners, insulating materials and adhesives, etc.

These components work together to enable LED lights to emit bright, stable and long-lasting light.

What electronic components are needed for LED lights?

Do you know about the electronic components of LED lights? Many friends are not very clear about it. Based on the many years of work experience of electronic component engineers, let me summarize it for you.

Electronic components and material composition of LED lights

Making LED lights requires a range of electronic components and materials.

Here is a detailed introduction to the basic components and materials required:

- LED lamp beads:

LED lamp beads are the core component of LED lamps and are responsible for generating light. Common LED lamp beads include direct plug-in type and SMD type. In-line LED lamp beads are suitable for low current and low voltage, while SMD LED lamp beads are suitable for high current and high voltage. LED lamp beads are available in red, green, blue, yellow, white and other colors, which can be selected according to needs. - Drive circuit:

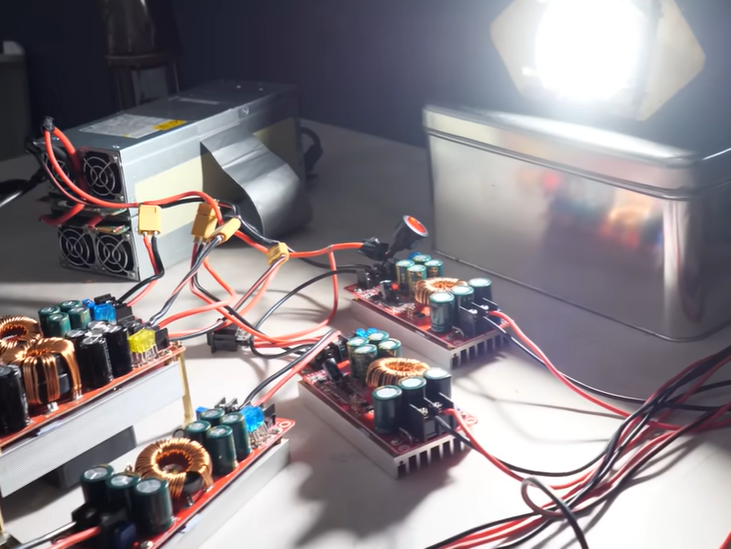

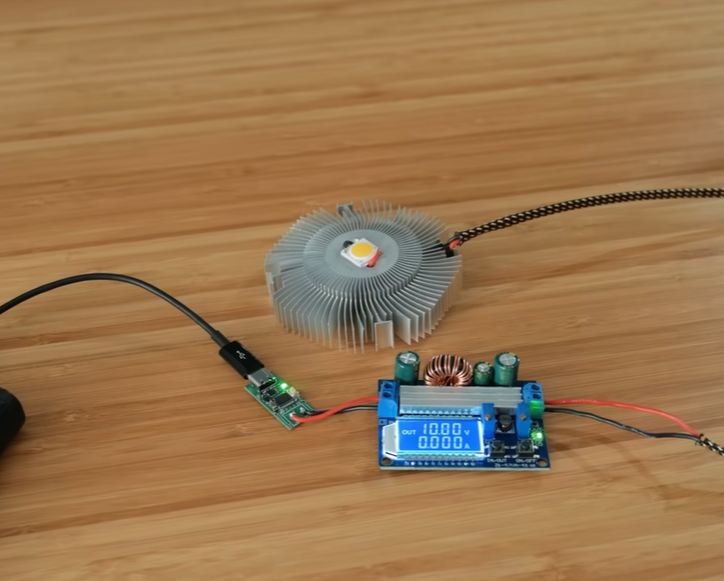

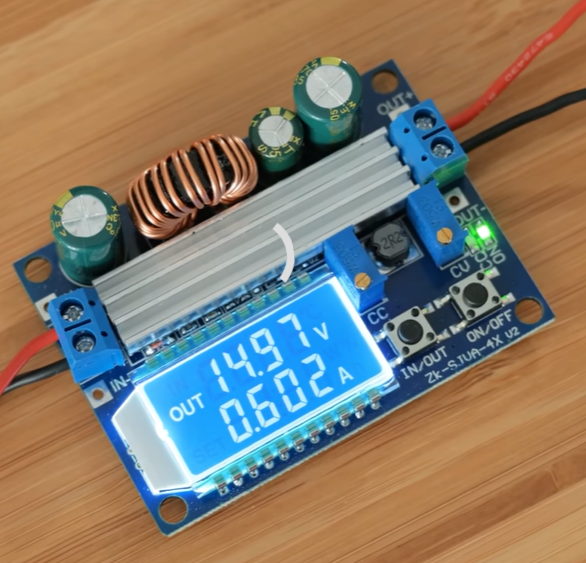

The drive circuit is responsible for providing stable current and voltage to the LED lamp beads. It usually consists of power supply, rectifier, filter and constant current source. The function of the drive circuit is to ensure the normal operation of the LED lamp beads and prevent overcurrent or overvoltage from damaging the lamp beads. - Radiator:

LED lamps will generate heat when working. If the heat dissipation is poor, the performance of the lamp beads will decrease, the light will attenuate or even be damaged. Therefore, a heat sink is needed to help dissipate heat and maintain the normal operating temperature of the LED lamp beads. Radiators are usually made of thermally conductive materials such as aluminum alloy and copper. - Lampshade:

The function of the lampshade is to diffuse light and make it more even and soft. Common lampshades include frosted glass, PC materials, etc., which can be selected according to specific needs. - Power cord:

The power cord is used to connect the LED light to the power socket and is responsible for transmitting power. Choose a power cord of appropriate length as needed and ensure it complies with relevant national standards. - Screws and other fasteners:

Fasteners such as screws are used to fix various parts of the LED light to ensure that it is firm and stable. Select appropriate screws and other fasteners as needed and ensure reliable quality. - Insulating materials:

During the assembly process of LED lights, insulating materials need to be used to protect circuits and lamp beads to prevent safety accidents such as short circuits and electric shocks. Insulating materials should have the characteristics of high temperature resistance and good insulation performance. - Adhesive:

Adhesives are used to bond the various parts of the LED light together to ensure they are strong and stable. Choose the right adhesive according to your needs and ensure reliable quality. Commonly used adhesives include silicone, 3M glue, etc. - Packing box:

The packaging box is used to protect the safety of the LED lights during transportation and storage. Choose the appropriate packaging box according to your needs and ensure reliable quality. The packaging box should be shockproof and waterproof.

In addition to the above basic components and materials, you need to pay attention to the following points when making LED lights:

- The specifications and parameters of LED lamp beads should comply with relevant standards and requirements, such as voltage, current, power, color temperature, etc. At the same time, it is necessary to choose LED lamp beads of regular brands and reliable quality to ensure stable performance and service life.

- The parameters of the drive circuit should match the LED lamp beads to ensure stable current and voltage. At the same time, pay attention to choosing a drive circuit with overcurrent and overvoltage protection functions to protect the LED lamp beads from damage.

- The design and materials of the radiator should fully consider the power and operating temperature of the LED light to ensure good heat dissipation. At the same time, pay attention to the quality and installation method of the radiator to prevent loosening or falling off.

- The material and design of the lampshade should have good light transmittance and scattering properties to ensure the softness and uniformity of the LED light. At the same time, pay attention to the quality and installation method of the lampshade to prevent cracking or falling off.

- Auxiliary materials such as power cords and fasteners should comply with relevant standards and requirements, such as national safety certification, etc. At the same time, pay attention to the quality and specifications of power cords and fasteners to prevent safety accidents or damage.

- During the assembly process, relevant operating procedures and technical requirements must be followed to ensure that the various components of the LED light are firmly and stably connected, and attention must be paid to safety matters and environmental protection requirements.

- During use, pay attention to the care and maintenance of LED lights, such as regularly cleaning the lampshade, checking the circuit, etc., to maintain its performance and service life. At the same time, pay attention to using the appropriate light source and voltage to prevent damage to the LED lights or shorten their service life.

Summary of the composition of LED lamp electronic components

Based on the above summary of the composition of LED light electronic components:

LED light electronic components: resistors, capacitors, diodes, LEDs, etc. Its main structure generally consists of: LED light source (LED light-emitting patch or small straw hat), radiator or heat dissipation substrate, constant current power supply, casing, other accessories, etc. .

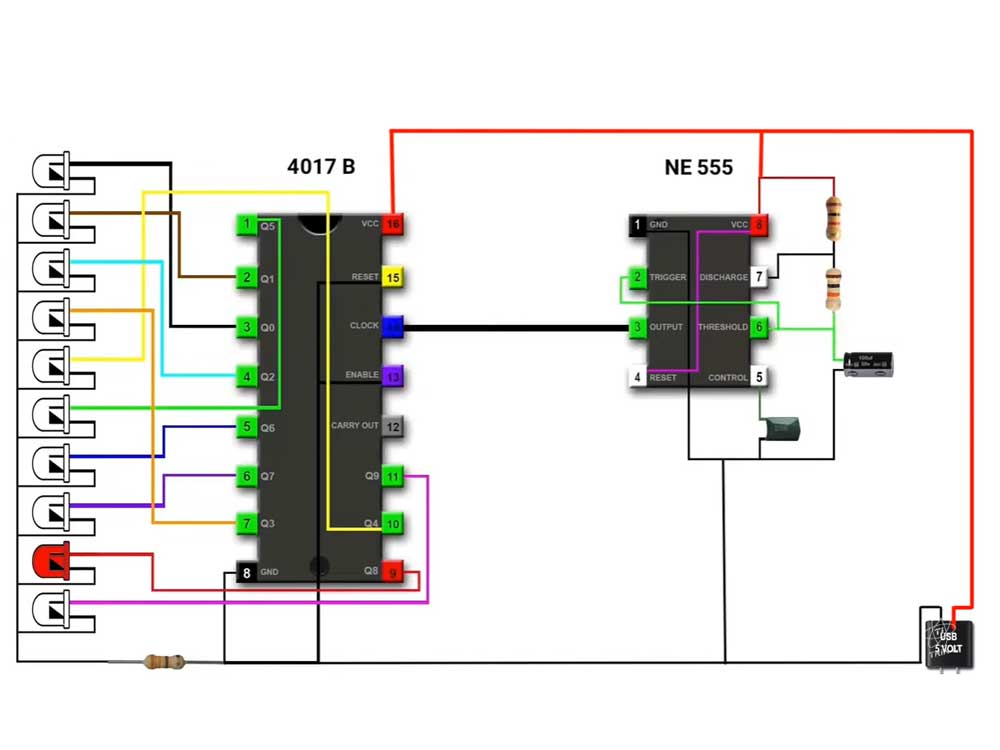

LED lights can be divided into constant-light types and changing LED types (also divided into internal control and external control). Generally, they are driven by a switching power supply. Of course, they can also be driven by diode rectifier + current-limiting resistor. Generally, capacitors will be used.

The main structure generally consists of: LED light source (LED light-emitting patch or small straw hat), radiator or heat dissipation substrate, constant current power supply, shell, other accessories, etc.

The above are the components of LED light electronic components. I believe we now have a deeper understanding of LED light electronic components. Please contact us to purchase electronic components.

FAQs

Making LED lights requires electronic components such as LED lamp beads, drive circuits, radiators, lampshades, power cords, fasteners such as screws, insulating materials and adhesives.

There are two types of LED lamp beads: direct plug-in type and SMD type. In-line LED lamp beads are suitable for low current and low voltage, while SMD LED lamp beads are suitable for high current and high voltage.

When choosing a suitable LED lamp bead, you need to consider its specifications and parameters, such as voltage, current, power, color temperature, etc. At the same time, it is necessary to choose LED lamp beads of regular brands and reliable quality to ensure stable performance and service life.

The function of the drive circuit is to provide stable current and voltage to the LED lamp beads to ensure their normal operation and prevent overcurrent or overvoltage from damaging the lamp beads.

The role of the radiator is to help dissipate heat, maintain the normal operating temperature of the LED lamp beads, and prevent performance degradation or damage caused by overheating.

Choosing a suitable radiator requires considering its material, design and specifications to fully consider the power and operating temperature of the LED light. At the same time, pay attention to the quality and installation method of the radiator to prevent loosening or falling off.

The function of the lampshade is to scatter light and make the light more uniform and softer. At the same time, it also plays a role in protecting LED lamp beads.

Choosing a suitable lampshade requires considering its material, design and specifications to have good light transmission and scattering properties. At the same time, pay attention to the quality and installation method of the lampshade to prevent cracking or falling off.