A voltage regulator chip is an electronic device used to stabilize voltage and is widely used in various electronic devices. Its manufacturing process involves multiple complex technical links, including material preparation, chip design, manufacturing process, testing, etc.

The manufacturing process and principles of the voltage regulator chip will be introduced in detail below.

Explain how the voltage regulator chip is manufactured and its principle analysis

The manufacturing method of voltage stabilizing chips includes chip design, manufacturing process and packaging testing. Chip design is a key step, and the circuit diagram and layout are designed according to application requirements.

The manufacturing process includes complex steps such as photolithography, etching, and ion implantation to transfer the designed layout to the silicon wafer to create circuit structures and components. Package testing involves packaging the chip in an appropriate package and testing it to ensure performance and stability.

The principle of the voltage stabilizing chip is to maintain a stable output voltage through internal circuit regulation.

The error amplifier detects the difference between the input voltage and the output voltage, and the adjustment tube adjusts the on-resistance according to the error signal to stabilize the output voltage.

Next, we will introduce in detail the manufacturing method and principle analysis of the voltage stabilizing chip.

Voltage regulator chip manufacturing material preparation

The main materials of voltage regulator chips include semiconductor materials, metal materials and ceramic materials. Among them, semiconductor materials are the core part of the chip. Commonly used semiconductor materials include silicon, germanium, etc. Metal materials are used to manufacture chip pins and heat sinks, while ceramic materials are used to manufacture chip packaging casings.

Voltage regulator chip design

The design of the voltage regulator chip mainly includes circuit design and layout design. Circuit design is to design the corresponding circuit diagram based on the functional requirements of the voltage regulator and determine the parameters and connection methods of each component.

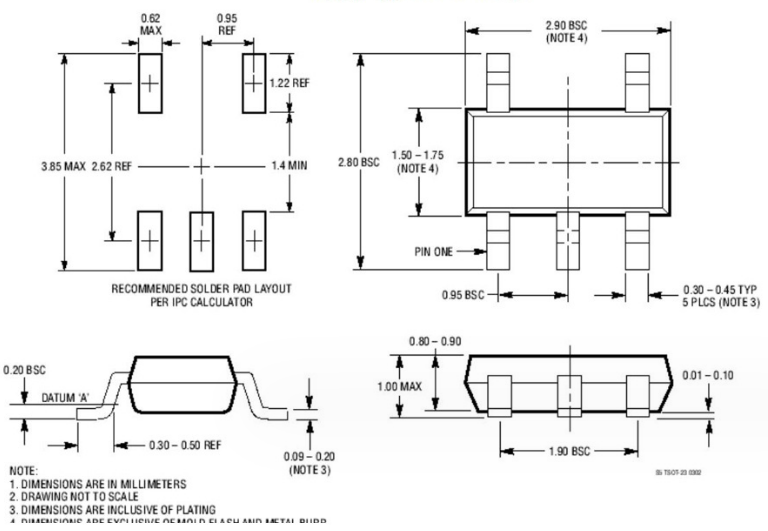

Voltage regulator chip circuit design layout structure diagram – Instructions for use of the 5V voltage regulator chip L5300AH with built-in thermal protection function

Layout design is to transform the circuit design into a specific physical structure, including the layout and wiring of components.

Voltage regulator chip manufacturing process

The manufacturing process of voltage regulator chips mainly includes thin film manufacturing, photolithography, etching, doping, etc.

- Thin film manufacturing: Through methods such as chemical vapor deposition or physical vapor deposition, a thin film of a certain thickness is formed on the surface of the chip. These thin films can be semiconductor materials, metal materials or insulating materials, etc.

- Photolithography: The designed circuit diagram is transferred to the chip surface through photolithography technology to form a mask for the circuit pattern.

- Etching: Using chemical or physical methods to remove unnecessary materials to form circuit patterns.

- Doping: By adding impurity elements to semiconductor materials, their conductive properties are changed to achieve circuit functions.

Voltage regulator chip testing and quality inspection

After manufacturing is completed, the voltage regulator chip needs to be tested to ensure that its performance and quality meet requirements. Testing includes electrical performance testing, reliability testing, environmental adaptability testing, etc.

Voltage regulator chip packaging and aging analysis

The voltage regulator chip that has passed the test needs to be packaged and aged. Packaging is to fix the chip in a package shell to protect the chip from the external environment. Aging is to run the chip under certain temperature and humidity conditions for a long time to test its stability and reliability.

What are the packaging methods of voltage regulator modules?

The packaging methods of voltage regulator modules mainly include the following:

Direct plug-in package

This packaging method inserts the voltage regulator chip directly into the socket on the circuit board and connects to the circuit board through pins. In-line packaging has the advantages of simple installation and low cost, but it takes up a lot of circuit board space.

surface mount package

Surface mount packaging is a packaging method in which the voltage regulator chip is directly soldered to the surface of the circuit board. This packaging method has the advantages of small size, light weight, and high reliability, so it has been widely used in electronic equipment.

Module packaging

Module packaging is to assemble multiple voltage regulator chips and other electronic components into a module, and then connect them to the circuit board through pins. Module packaging has the advantages of high integration and easy maintenance, so it has been widely used in some complex circuits.

Different packaging methods are suitable for different applications and different electronic devices. When selecting the packaging method of the voltage regulator module, comprehensive considerations need to be made based on factors such as specific application requirements and circuit board space.

Voltage regulator chip packaging process

The packaging process of the voltage regulator chip mainly includes pin welding, shell packaging, marking and other links.

- Pin welding: Weld the pins of the chip to the pins of the package shell to connect the chip to the external circuit. Pin welding can be done manually or automatically.

- Shell packaging: The chip is placed in the packaging shell, and the pins of the shell are connected to the pins of the chip. At the same time, the protection of the shell prevents the chip from being affected by the external environment. The shell package can be made of metal, ceramics and other materials.

- Marking: After the packaging is completed, the chip surface needs to be marked, including chip model, production date and other information, for subsequent identification and use.

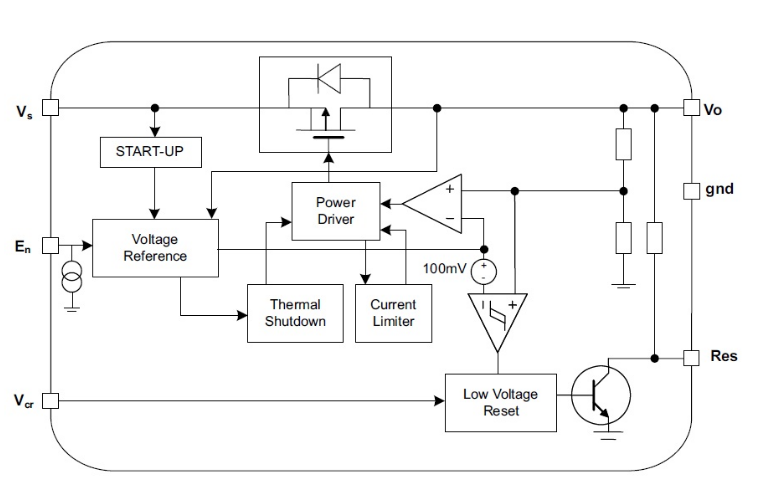

Principle Analysis of Voltage Regulator Chip

The principle of voltage regulator chips is mainly based on voltage regulation and current limiting. Through the regulation of the internal circuit, the output voltage is maintained within a stable range while limiting the output current to not exceed a safe range. Specifically, voltage regulator chips typically use linear or switching power supply technology to achieve voltage regulation and current limiting. Linear voltage regulators use linear adjustment tubes to adjust the output voltage, which have the advantages of low power consumption and low noise; switching power supply voltage regulators use switching tubes to adjust the output voltage, which have the advantages of high efficiency and small size.

In the voltage regulator chip, the realization of voltage regulation and current limitation also involves some key technical links, such as error amplifier, comparator, power tube, etc. The error amplifier is used to detect the error between the output voltage and the reference voltage, and amplify the error signal and pass it to the comparator; the comparator compares the error signal with the internal reference voltage, and controls the on and off of the power tube based on the comparison result; The power tube adjusts the output voltage and current according to the control signal of the comparator.

In short, the manufacturing process of voltage regulator chips involves many complex technical links, including material preparation, chip design, manufacturing process, testing, etc. Its principle is mainly based on the realization of voltage regulation and current limitation. Through the regulation of the internal circuit, the output voltage is maintained within a stable range and the output current is limited to not exceed a safe range.

Precautions for voltage regulator chip packaging process

When performing the packaging process of the voltage regulator chip, you need to pay attention to the following points:

- When welding pins, ensure the welding quality and avoid virtual welding, cold welding and other phenomena.

- When encapsulating the shell, ensure sealing to prevent moisture, dust, etc. from entering the inside of the chip.

- Marking should be clear and accurate to facilitate subsequent identification and use.

Development Trend of Voltage Regulator Chip Packaging Process

With the continuous development of technology, the packaging process of voltage regulator chips is also constantly improving. In the future, as chip sizes continue to shrink and integration levels continue to increase, the requirements for packaging processes will become more stringent. Therefore, it is necessary to continuously improve and optimize the packaging process to improve production efficiency and product quality. At the same time, with the continuous improvement of environmental awareness, green and environmentally friendly packaging materials and processes will also become a future development trend.